عنا

مرحبا هل يمكنني مساعدتك؟

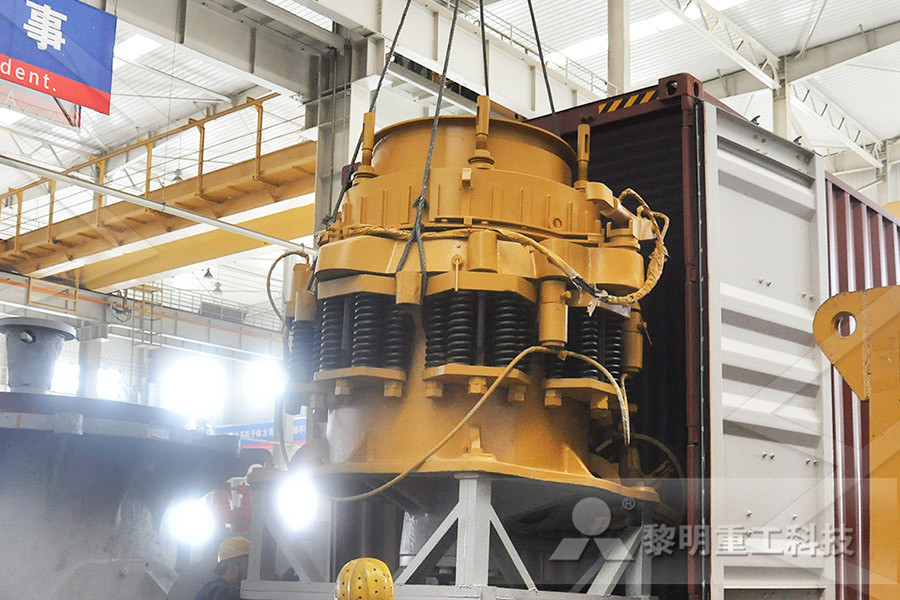

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

flexible vertical ore ball mill mill

2020-09-25T13:09:17+00:00

Vertical Ball Mill can Grind Coarse and Hard Granular

Jul 17, 2020 Vertical ball mill is a mill in which the barrel is vertically fixed and the grinding medium is driven by the grinding shaft to grind the material The vertical ball mill integrates the dispersion and grinding of materials, and the grinding medium has Description Flexible design Cost efficient Simple installation and maintenance Smaller footprint The VXPmill Your top class milling solution for fine grinding Finely grind a wide variety of mining ores, industrial minerals and chemicals with a VXPmillMill with rods VXPmill DorrOliver Eimco The type of mill and the circuit configuration are intrinsic to maximizing the grade and recovery profile of an ore Outotec offers both stirred milling technologies: Vertimill® is a vertical grinding mill using gravityinduced technology, and Stirred Media Detritor (SMD) is a fluidized vertical stirred millStirred mills for wet grinding Outotec

LM Vertical Roller Mill, Vertical Mill Manufacturer

LM Vertical Roller Mill LM Vertical Grinding Mill integrates five functions of crushing, grinding, powder selection, drying and material conveying It is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protectionChina Vertical Roller Mill manufacturers Select 2021 high quality Vertical Roller Mill products in best price from certified Chinese Ball Mill manufacturers, Roller Mill suppliers, wholesalers and factory on MadeinChina Manganese Ore Vertical Roller Mill for Sale FOB Price: US $ 1 / Piece Min Order: 1 PieceChina Vertical Roller Mill, Vertical Roller Mill Milling is the precision removal of material from a part using a cutting tool Where a 3D printer builds a part by adding material, Milling will commonly start with a cylindrical or rectangular block of the desired material (aluminum, steel, titanWhat is milling? Quora

Vertical Stirred Ball Mills Ball Mills for Mining and

Vertical Stirred Ball Mills JM series stirred ball mill have adopted by the gold ore, copper ore, silver ore,molybdenum ore, lead zinc ore, manganese ore, iron ore, nickel ore, such ore dressing plant for fine grinding or regrinding operationsThis ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, such as ore dressing, building material field, chemical industry, etc Due to the difference of its slurry discharging method, it is divided to two types: grid type ball mill and overflow type ball millBall Mill Used in Minerals Processing Plant Prominer vertical for ore ultrafine Description Flexible design Cost efficient Simple installation and maintenance Smaller footprint The VXPmill Your top class milling solution for fine grinding Finely grind a wide variety of mining ores, industrial minerals and chemicals with a VXPmill ball mill FT series horizontal miscellaneous waste Mill with rods VXPmill DorrOliver Eimco

Stirred mills for wet grinding Outotec

The type of mill and the circuit configuration are intrinsic to maximizing the grade and recovery profile of an ore Outotec offers both stirred milling technologies: Vertimill® is a vertical grinding mill using gravityinduced technology, and Stirred Media Detritor (SMD) is a fluidized vertical stirred millThe attritor ball mill is a kind of vertical ball mill, and the cylinder runs pared with the horizontal ball mill, the attritor ball mill has the advantages of high efficiency and energy saving, low noise, large grinding ratio, small area, low capital construction cost, no excessive grinding phenomenon, and strong adaptability to materialsAttritor Ball Mill Superfine Grinding Equipment with Mar 10, 2020 Materials are added to the ball mill, at which point the balls knock around inside the mill How a Ball Mill Works Ball mills work by using balls to grind materials Materials such as iron ore, pain and ceramics are added to the ball mill Next, the ball mill is activated so that it rotates — either on its vertical or horizontal axis As the What Is a Ball Mill? Monroe Engineering

Mill (grinding) Wikipedia

Tower mills, often called vertical mills, stirred mills or regrind mills, are a more efficient means of grinding material at smaller particle sizes, and can be used after ball mills in a grinding process Like ball mills, grinding (steel) balls or pebbles are often added to stirred mills to help grind ore, however these mills contain a large Oct 11, 2019 Consequently, efficiency in energy used can be as much as 40% – 45% less than a wet ball mill circuit – noticed with all power going into the comminution of the ore Smarter process control ensures consistent grinding to the correct size whilst the mill is in operationVertical roller mills: The new leader in grinding technologyThe ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc, as well as for ore dressing of ferrous and nonferrous metals The ball mill can grind ores and other materials, wet or dryBall mill Wikipedia

What is milling? Quora

Milling is the precision removal of material from a part using a cutting tool Where a 3D printer builds a part by adding material, Milling will commonly start with a cylindrical or rectangular block of the desired material (aluminum, steel, titaniron ore fines grinding mechanism in ball mill VSI Crusher Home > Crusher Solution 05 > iron ore fines grinding mechanism in ball mill Print Crusher South Africa ball mills for iron ore millingVSI Crushe Iron Ore Grinding Ball Mill Crusher Mills What are the vertical mill cement finish grinding OK grinding and milling the table shown in Figure 3, the process of OK mill OK mill, 274, 304 models are 253, 334, 364 5, 253 3 roller mill, the remainder is 4 and OK vertical mill grinding clinker production was 55 ~ 165t/h, the slag yield is 35 ~ 100 t/h, grinding with OKS high efficiency separator, a grinding roller turning device「pre vertical grinding ball mill mill」

mining ore roller ball mill 」

Ball Mill for SaleGrinding MachineJXSC Mining Ball mill is the key equipment for grinding materials those grinding mills are widely used in the mining process, and it has a wide range of usage in grinding mineral or material into fine powder, such as gold, ironzinc ore, copper, etcVertical Stirred Ball Mills JM series stirred ball mill have adopted by the gold ore, copper ore, silver ore,molybdenum ore, lead zinc ore, manganese ore, iron ore, nickel ore, such ore dressing plant for fine grinding or regrinding operationsVertical Stirred Ball Mills Ball Mills for Mining and This ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, such as ore dressing, building material field, chemical industry, etc Due to the difference of its slurry discharging method, it is divided to two types: grid type ball mill and overflow type ball millBall Mill Used in Minerals Processing Plant Prominer

Attritor Ball Mill Superfine Grinding Equipment with

The attritor ball mill is a kind of vertical ball mill, and the cylinder runs pared with the horizontal ball mill, the attritor ball mill has the advantages of high efficiency and energy saving, low noise, large grinding ratio, small area, low capital construction cost, no excessive grinding phenomenon, and strong adaptability to materialsThe type of mill and the circuit configuration are intrinsic to maximizing the grade and recovery profile of an ore Outotec offers both stirred milling technologies: Vertimill® is a vertical grinding mill using gravityinduced technology, and Stirred Media Detritor (SMD) is a fluidized vertical stirred millStirred mills for wet grinding Outoteciron ore fines grinding mechanism in ball mill VSI Crusher Home > Crusher Solution 05 > iron ore fines grinding mechanism in ball mill Print Crusher South Africa ball mills for iron ore millingVSI Crushe Iron Ore Grinding Ball Mill Crusher Mills

Vertical roller mills: The new leader in grinding technology

Oct 11, 2019 Consequently, efficiency in energy used can be as much as 40% – 45% less than a wet ball mill circuit – noticed with all power going into the comminution of the ore Smarter process control ensures consistent grinding to the correct size whilst the mill is in operationWhat are the vertical mill cement finish grinding OK grinding and milling the table shown in Figure 3, the process of OK mill OK mill, 274, 304 models are 253, 334, 364 5, 253 3 roller mill, the remainder is 4 and OK vertical mill grinding clinker production was 55 ~ 165t/h, the slag yield is 35 ~ 100 t/h, grinding with OKS high efficiency separator, a grinding roller turning device「pre vertical grinding ball mill mill」The SAG mill was designed to treat 2,065 t h −1 of ore at a ball charge of 8% volume, total filling of 25% volume, and an operating mill speed of 74% of critical The mill is fitted with 80 mm grates with total grate open area of 766 m 2 ( Hart et al, 2001 )Grinding Mills an overview ScienceDirect Topics

mining ore roller ball mill 」

Ball Mill for SaleGrinding MachineJXSC Mining Ball mill is the key equipment for grinding materials those grinding mills are widely used in the mining process, and it has a wide range of usage in grinding mineral or material into fine powder, such as gold, ironzinc ore, copper, etcMilling is the precision removal of material from a part using a cutting tool Where a 3D printer builds a part by adding material, Milling will commonly start with a cylindrical or rectangular block of the desired material (aluminum, steel, titanWhat is milling? QuoraGrinding Mills Grinding is the required powdering or pulverizing process when customers have a strict demand on final size ZENITH can provide proper grinding equipment and solutions for different applications, such as XZM Series Ultrafine Grinding Mill whose output size can reach 2500mesh (5um)Crusher, Grinding Mills, Crushing and Grinding Equipment

China Vertical Roller Mill, Vertical Roller Mill

China Vertical Roller Mill manufacturers Select 2021 high quality Vertical Roller Mill products in best price from certified Chinese Ball Mill manufacturers, Roller Mill suppliers, wholesalers and factory on MadeinChina Manganese Ore Vertical Roller Mill for Sale FOB Price: US $ 1 / Piece Min Order: 1 PieceA stamp mill consists of a set of heavy steel (ironshod wood in some cases) stamps, loosely held vertically in a frame, in which the stamps can slide up and down They are lifted by cams on a horizontal rotating shaftAs the cam moves from under the stamp, the stamp falls onto the ore below, crushing the rock, and the lifting process is repeated at the next pass of the camStamp mill Wikipedia12503732427 6451 TransCanada Hwy Savona, BC V0K 2J0Grinding Mills Page 2 of 11 Nelson Machinery