عنا

مرحبا هل يمكنني مساعدتك؟

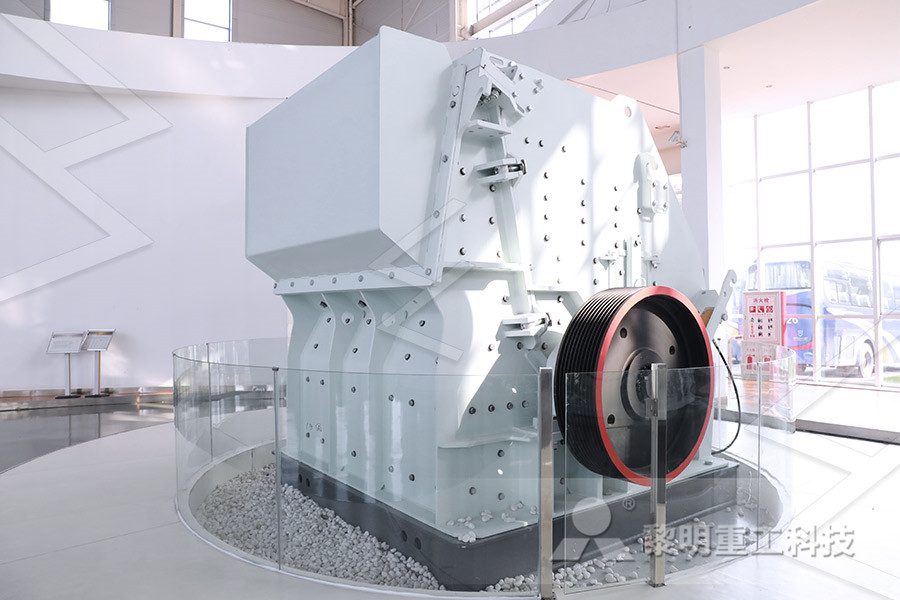

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

ball mill nditions

2021-06-12T06:06:13+00:00

Ball Mill an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightApr 28, 2017 Table of ContentsOpen Circuit GrindingClosed Circuit GrindingSingle Stage GrindingTwo Stage GrindingFirst Stage of Ball MillingSecond Stage of Ball MillingLarge VS Small Grinding BallsRelation between Speed of Mill Size of Balls in MillDeductions from Operating TestsDesign Regulation of a Fine Crushing PlantMechanics inside a Ball MillAction of Charge at Slow Ball Mill Grinding Theory Crushing Motion/Action InsideBall mills characterized by high energy consumption When the mill idles, the energy consumption is approximately equal to the energy consumption with full mill capacity Therefore, the work of the mill with partial load conditions is unprofitableThe operating principle of the ball mill Primo Pizza

Ball Mill: Operating principles, components, Uses

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill sizeBall Mill Design A survey of Australian processing plants revealed a maximum ball mill diameter of 524 meters and length of 884 meters (Morrell, 1996) Autogenous mills range up to 12 meters in diameter The lengthtodiameter ratios in the previous table are for normal applicationsAMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill But the mill is operated at a speed of 15 rpm Therefore, the mill is operated at 100 x 15/307 = 4886 % of critical speed If 100 mm dia balls are replaced by 50 mm dia balls, and the other conditions are remaining the same, Speed of ball mill = [04886/ (2 p)] x [9812/ (1 0025)] 05Ball Mill Operating Speed Mechanical Operations Solved

Ball Nose Finishing Mills Speed Feed Calculator DAPRA

Ball Nose Finishing Mills Speed Feed Calculator Instructions: Fill in the blocks shaded in blue with your application information The calculator will automatically provide the necessary speed and feed in Cobalt Steel Ball End Mills with Two Milling Ends With better heat and wear resistance than highspeed steel, these cobalt steel end mills can run at higher speeds and provide better performance on hard material, such as cast iron, hardened steel, titanium, and tool steelBall End Mills McMasterCarrA ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Ball mill Wikipedia

Ball Mill Operating Speed Mechanical Operations Solved

At what speed will the mill have to be run if the 100 mm balls are replaced by 50 mm balls, all the other conditions remaining the same? Calculations: The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball For R = 1000 mm and r = 50 mm, n c = 307 rpm But the mill A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill Ball Mill: Operating principles, components, Uses A ball mill, a type of crusher, is a cylindrical device used to grind chemicals or mix compositions Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium, ideally non sparking milling media like lead balls An internal cascading effect reduces the material to a fine powderBall mill PyroData

Temperature progression in a mixer ball mill SpringerLink

Apr 22, 2016 Mechanochemistry using ball mills is a promising technique with applications in organic and inorganic chemistry as well as material sciences [1–4]During ball milling, up to 80 % of the energy that is generated in the mill is dissipated as heat []This is why measurement and control of the temperature in the ball mills is important, for example, if heatsensitive products are formed that Cobalt Steel Ball End Mills with Two Milling Ends With better heat and wear resistance than highspeed steel, these cobalt steel end mills can run at higher speeds and provide better performance on hard material, such as cast iron, hardened steel, titanium, and tool steelBall End Mills McMasterCarrBall Nose Finishing Mills Speed Feed Calculator Instructions: Fill in the blocks shaded in blue with your application information The calculator will automatically provide the necessary speed and feed in Ball Nose Finishing Mills Speed Feed Calculator DAPRA

194 questions with answers in BALL MILLING Science topic

Feb 19, 2021 "In a typical synthesis, 0012 mol Li2CO3 (An excess of 20 mol% Li2CO3 was added to compensate for Li loss during processing), 001 mol La2O3, and 004 mol TiO2, were mixed and ball The High Energy Ball Mill Emax combines highfrequency impact, intensive friction, and controlled circular jar movements to a unique and highly effective size reduction mechanism The grinding jars have an oval shape and are mounted on two discs respectively which move the jars on a circular course without changing their orientationEmax High Energy Ball Mill RetschBallMill Base with Ventilated MotorCover Installed BallMill Base with Ventilated MotorCover Removed The BallMill Drive System Looking inside the mill's motor compartment, you can now see the motor, with a small fan and pulley on its shaft That small pulley is connected by a drive belt to a large pulley which is mounted on the unit's drive Quick and Easy Black Powder Ball Mill — Skylighter, Inc

Playing ball with the Haber–Bosch process Advanced

Dec 23, 2020 In an eyeopening recent report it was demonstrated that the ammonia synthesis process could be powered mechanochemically in a simple ball mill laboratory experiment under the seemingly very gentle conditions of 45 °C and 1 atmosphere The mechanochemical ammonia yield reported was found to be significantly higher than the Haber–BoschA lipasecatalyzed esterification of lignin model compounds in the ball mill was developed combining the advantages of enzyme catalysis and mechanochemistry Under the described conditions, the primary aliphatic hydroxy groups present in the substrates were selectively modified by the biocatalyst to afford monoesterified productsBJOC Selective enzymatic esterification of lignin model The effect of ball mill on the morphological and structural features of cellulose has been described by Okajima and coworkers 20 They treated microcrystalline cellulose derived from cotton linters in a planetary ball mill at 200 rpm for 4–8 hours in dry and wet conditions with three solvents (water, toluene, 1butanol) They observed that Ball milling: a green technology for the preparation and

[PDF] Effects of Ball Milling Conditions on Breakage

The effects of ball milling conditions on breakage response of Baban Tsauni (Nigeria) leadgold ore was examined in this research work The three factors considered were, the grinding media mass to ore sample mass ratio, the grinding time and the ball mill speed The breakage response measured in terms of cumulative per cent mass passing the liberation size increased with increase in media A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill Ball Mill: Operating principles, components, Uses Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill Ball Mills Mineral Processing Metallurgy

Ball End Mills McMasterCarr

Cobalt Steel Ball End Mills with Two Milling Ends With better heat and wear resistance than highspeed steel, these cobalt steel end mills can run at higher speeds and provide better performance on hard material, such as cast iron, hardened steel, titanium, and tool steelPlanetary Ball Mills are used wherever the highest degree of fineness is requiredIn addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical alloyingThe extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and Planetary Ball Mill PM 100 RETSCH highest finenessDec 23, 2020 In an eyeopening recent report it was demonstrated that the ammonia synthesis process could be powered mechanochemically in a simple ball mill laboratory experiment under the seemingly very gentle conditions of 45 °C and 1 atmosphere The mechanochemical ammonia yield reported was found to be significantly higher than the Haber–BoschPlaying ball with the Haber–Bosch process Advanced

Ball End Mills MSC Industrial Supply

Ball end mills, also known as ball nose end mills, are used for milling contoured surfaces, slotting and pocketing A ball end mill is constructed of a round cutting They have a ball end for milling rounded slots, slopes, and contours All are center cutting, allowing plunge cuts into a surface End mills with fewer flutes provide better chip clearance for high volume, highspeed plunge, slotting, and roughing cuts; end mills with more flutes provide a finer finish and operate with less vibration when run DiamondCoated End Mills McMasterCarrOur SAG mill strategies automatically adjust feed rate, mill speed and water addition to reduce upsets , eliminate grindouts, protect liners/lifters, and increase tonnage We maintain desired operating conditions by constantly monitoring bearing pressure, mill power, recycle pebbles, mill density, charge toe and mill acoustics,GrindingExpert™ WordPress

Ball Home

Ball Corporation is the world’s leading provider of innovative, sustainable aluminum packaging for beverage, personal care and household products, as well Purchasing Conditions; DFARS/FARS; Contact; Astm A449; Ball mill liner bolts; Bolt Manufacturers; Custom Fasteners; Double Ended Stud; Large Bolts; Large Nuts; Mining bolts; Mining bolts and nuts; Socket Head Cap Screw; Types of ball mill liners; ArticlesProducts – Dyson CorpApr 22, 2016 Mechanochemistry using ball mills is a promising technique with applications in organic and inorganic chemistry as well as material sciences [1–4]During ball milling, up to 80 % of the energy that is generated in the mill is dissipated as heat []This is why measurement and control of the temperature in the ball mills is important, for example, if heatsensitive products are formed that Temperature progression in a mixer ball mill SpringerLink

[PDF] Effects of Ball Milling Conditions on Breakage

The effects of ball milling conditions on breakage response of Baban Tsauni (Nigeria) leadgold ore was examined in this research work The three factors considered were, the grinding media mass to ore sample mass ratio, the grinding time and the ball mill speed The breakage response measured in terms of cumulative per cent mass passing the liberation size increased with increase in media SPEED TIGER ISB Carbide Ball Nose End Mill Micro Grain Carbide End Mill for Alloy Steels/Hardened Steels 2 Flute ISB5/16"2T Made in Taiwan (1 Piece, 5/16") 43 out of 5 stars 24 MiscAmazon: Ball Nose End Mills: Industrial ScientificOpen gearing applications, particularly those associated with ball mill and finishing mill applications, are considered some of the most difficult applications a lubricant can encounter Generally, these types of open gears operate at low pitch line velocities and/or under heavy loadsPractical Lubrication of Open Gearing