عنا

مرحبا هل يمكنني مساعدتك؟

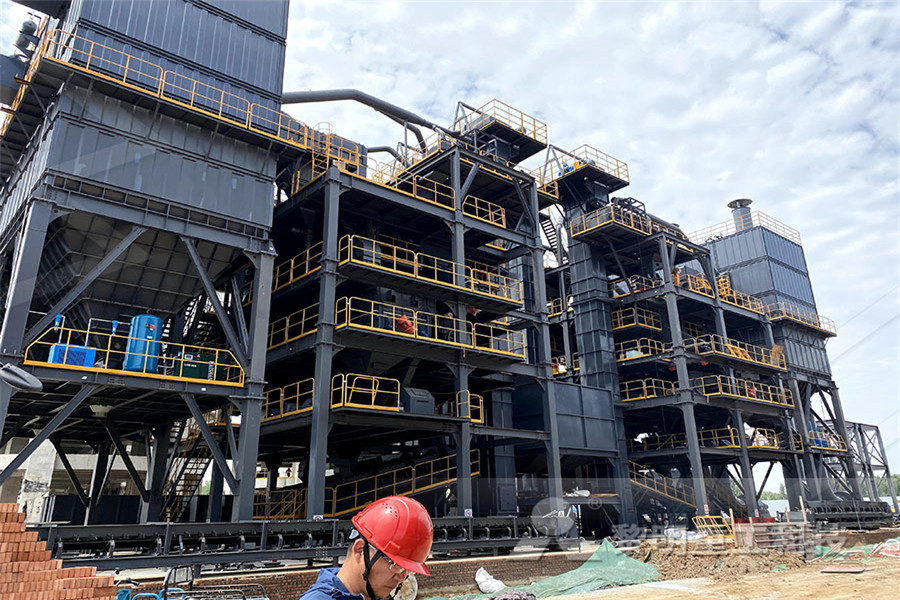

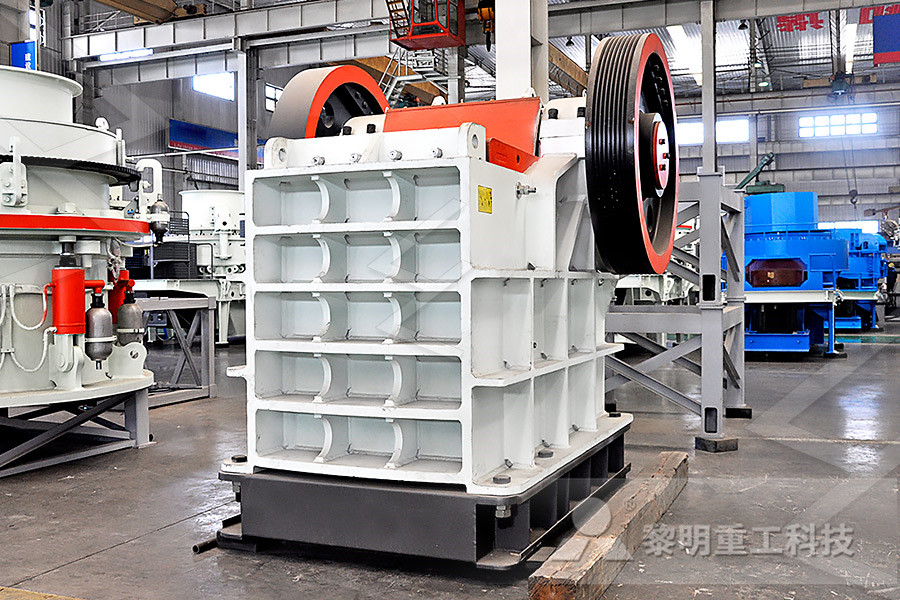

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Polyethylene Coating System For Pipeline

2019-10-09T16:10:45+00:00

(PDF) Advanced two layer polyethyelene coating

Polyethylene (2LPE) and 3 Layer Polyethylene (3LPE) coating system s Corrosion Control 007 Paper 039 Page 2 fibers in a unique construction to create a spoolable high pressure pipeline systemPOLYETHYLENE COATING TECHNOLOGY FOR PIPELINE PROTECTION S Guan1, A novel approach was taken in this study by formulating a twolayer pipe coating system ADVANCED TWO LAYER POLYETHYLENE COATING PRD’s Polyethylene Tape Coating Systems offer an alternative to PE extrusion coating The system produces pipe with ciatings for conveying industrial, raw, waste and drinking water An Epoxy primer bonds the steel to the adhesive layer The inner PE adhesive layer offers corrosion protection and tightly bonds to the outer PE coatingPOLYETHYLENE TAPE COATING WRAPPING – PRD

3LPE Coated Pipes 3 Layer Polyethylene Pipe Coating

get 3 layer pe pipe coating here, know more about threelayer polyethylene pipe coatings price 3LPE Coated Pipes consist of 3 layers for pipeline coating First layer of 3LPE Coating consists of Fusion Bonded Epoxy This coating provides protection against corrosion and is fusionbonded with the blasted steel surfaceCopolymer adhesive resin Lushan L5R series is maleic grafted polyethylene in granule or powder form It's mainly used as adhesive layer in 3 layers polyethylene system(3LPE) for steel pipe anticorrosion coating in oil and gas pipeline and water pipeline3layer anticorrosion Coating System for Oil and Gas The applied coating system shall comply to properties of coating system 30 Inspection and Testing @ Pipe Three Layer Polyethylene Coating Specification Regular / Commercial Production shall be commenced after getting approval from the Customer/Customer’s representativePipe Three Layer Polyethylene Coating Specification

3lpe Coated Pipe and ISO 21809 3 Layer PE Coating

We can offer 3lpe Coated Pipes, 3 Layer Polyethylene Coating Pipeline DIN 30670 Coated Steel Pipe at low cost The epoxy in the 3lpe Pipe is a powder material that is added to the metal pipe surface by a process called as the fusion bonding The 3lpe Pipeline Coating is essential in systems that transport and contain highly reactive or coating system provides physical and mechanical advantages ELASTOMER (NEOPRENE) Elastomer coating is the most effective anticorrosion system for risers used in offshore operations, especially in the highly corrosive splash zone region Threelayer polypropylene and polyethyleneOffshore and Onshore Pipeline Coating SolutionsPolyethylene also may be used to protect against stray direct currents Additionally, polyethylene wrap reduces soiltopipe friction, and this characteristic must be taken in to account in the design of a restrained pipeline system Coatings can provide total electrical insulation between different pipeline The Use of Coatings and Polyethylene for Corrosion

(PDF) Advanced two layer polyethyelene coating

Polyethylene (2LPE) and 3 Layer Polyethylene (3LPE) coating system s Corrosion Control 007 Paper 039 Page 2 fibers in a unique construction to create a spoolable high pressure pipeline system2 天前 Three Layer Polyethylene Coating (3LPE) External polyethylene coating is a plantapplied coating system applied externally to provide excellent anticorrosion protection for steel line pipes and fittings, intended primarily for buried or submerged service for water or oil and gas pipeline system, including twolayer (2LPE) and threelayer (3LPE) coating systems, whereby a copolymer adhesive is External Polyethylene Coating pipecoatindoThe applied coating system shall comply to properties of coating system 30 Inspection and Testing @ Pipe Three Layer Polyethylene Coating Specification Regular / Commercial Production shall be commenced after getting approval from the Customer/Customer’s representativePipe Three Layer Polyethylene Coating Specification

3layer anticorrosion Coating System for Oil and Gas

Copolymer adhesive resin Lushan L5R series is maleic grafted polyethylene in granule or powder form It's mainly used as adhesive layer in 3 layers polyethylene system(3LPE) for steel pipe anticorrosion coating in oil and gas pipeline and water pipeline 3Layer Polyethylene (3LPE) is a multilayer coating composed of three functional components: A high performance Fusion Bonded Epoxy (FBE) primer, followed by a copolymer adhesive and an outer layer of polyethylene which provides tough, durable protection 3LPE systems provide excellent pipeline protection for small and large diameter pipelines operating at up to moderately high 3LPE ShawcorPolyethylene also may be used to protect against stray direct currents Additionally, polyethylene wrap reduces soiltopipe friction, and this characteristic must be taken in to account in the design of a restrained pipeline system Coatings can provide total electrical insulation between different pipeline The Use of Coatings and Polyethylene for Corrosion

Offshore and Onshore Pipeline Coating Solutions

coating system provides physical and mechanical advantages ELASTOMER (NEOPRENE) Elastomer coating is the most effective anticorrosion system for risers used in offshore operations, especially in the highly corrosive splash zone region Threelayer polypropylene and polyethyleneFusionkote Fusionkote is a Fusion Bonded Medium Density Polyethylene (FBMDPE) coating developed by PLC Upon receiving Australian Standard Certification to AS4321:2001 in December 2014, Fusionkote has found a highly receptive market and offers our Water Industry clients an independent and alternative source for this industry preferred coating systemFusionkote Pipe Lining Coating Pty Ltd Polyethylene Pipeline Systems Avoiding The Pitfalls of Fusion Welding Dr Chris O’Connor Senior Consultant GL Noble Denton (Oil Gas) United Kingdom Abstract Polyethylene (PE) has revolutionized low pressure pipe system design on a global basis and is testimony to PE’s unique combination of properties, which have drivenPolyethylene Pipeline Systems Avoiding The Pitfalls of

Coatings in Pipelines all about pipelines

This article details the various coating systems which are applied on hydrocarbon pipelines nowadays It also provides the properties which desired in an effective pipeline coating system and provides a comparative study between FBE, CTE and 3LPE coatings based on those propertiesPolyethylene (2LPE) and 3 Layer Polyethylene (3LPE) coating system s Corrosion Control 007 Paper 039 Page 2 fibers in a unique construction to create a spoolable high pressure pipeline system(PDF) Advanced two layer polyethyelene coating Pipeline Polyethylene 3ply Tape (T 4100 ) I Description TheT400 series is Cold applied tape coating system for corrosion protection of Oil, Gas, Petrochemical, and Waste Water underground or China Pipeline Polyethylene 3ply Tape China

External Polyethylene Coating pipecoatindo

2 天前 Three Layer Polyethylene Coating (3LPE) External polyethylene coating is a plantapplied coating system applied externally to provide excellent anticorrosion protection for steel line pipes and fittings, intended primarily for buried or submerged service for water or oil and gas pipeline system, including twolayer (2LPE) and threelayer (3LPE) coating systems, whereby a copolymer adhesive is Three Layer Polyethylene Coating is a kind of highly resistant, durable, and efficient coating which is used for various pipeline transferring oil, gas, water and other liquids Three layer polyethylene coating, is highly adhesive and tightly adheres to the steel pipes and protects them in several aspectsThree Layer Polyethylene CoatingThe applied coating system shall comply to properties of coating system 30 Inspection and Testing @ Pipe Three Layer Polyethylene Coating Specification Regular / Commercial Production shall be commenced after getting approval from the Customer/Customer’s representativePipe Three Layer Polyethylene Coating Specification

2Layer Polyethylene Extruded FactoryApplied Pipe

The 2layer polyethylene (PE) coating system has been used in the oil, gas, and water industry for the past 48 years for potable, waste water, and water treatment for both steel and ductile iron (DI) pipe Also addressed are mainline coatings and those utilized in conjunction using heat shrink sleeves and polyethylene tape coating systems for 3Layer Polyethylene (3LPE) is a multilayer coating composed of three functional components: A high performance Fusion Bonded Epoxy (FBE) primer, followed by a copolymer adhesive and an outer layer of polyethylene which provides tough, durable protection 3LPE systems provide excellent pipeline protection for small and large diameter pipelines operating at up to moderately high 3LPE Shawcorcoating system provides physical and mechanical advantages ELASTOMER (NEOPRENE) Elastomer coating is the most effective anticorrosion system for risers used in offshore operations, especially in the highly corrosive splash zone region Threelayer polypropylene and polyethyleneOffshore and Onshore Pipeline Coating Solutions

Fusionkote Pipe Lining Coating Pty Ltd

Fusionkote Fusionkote is a Fusion Bonded Medium Density Polyethylene (FBMDPE) coating developed by PLC Upon receiving Australian Standard Certification to AS4321:2001 in December 2014, Fusionkote has found a highly receptive market and offers our Water Industry clients an independent and alternative source for this industry preferred coating system Polyethylene Pipeline Systems Avoiding The Pitfalls of Fusion Welding Dr Chris O’Connor Senior Consultant GL Noble Denton (Oil Gas) United Kingdom Abstract Polyethylene (PE) has revolutionized low pressure pipe system design on a global basis and is testimony to PE’s unique combination of properties, which have drivenPolyethylene Pipeline Systems Avoiding The Pitfalls of