عنا

مرحبا هل يمكنني مساعدتك؟

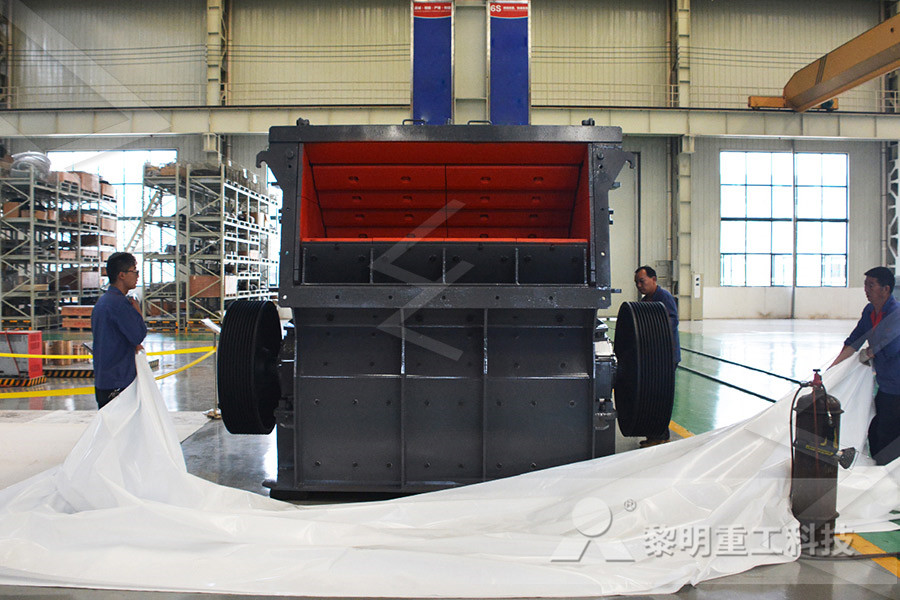

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

flow process ball mill

2019-01-27T20:01:16+00:00

Ball Mill Flow Process

ball mill process flow Ball mill process knowledge beijing power equipment ,therefore, it is unwise to use the open flow system in the new grinding station ball mill system when using the closedcircuit grinding process, if the osepa separator is used to introduce the coldair powder, the cement temperature can be reduced by compared with the openpath millget priceThe vector stencils library "Industrial equipment" contains 81 symbols of pumps, compressors, fans, turbines, and power generators Use these shapes to design pumping systems, air and fluid compression systems, and industrial process diagrams in the ConceptDraw PRO software extended with the Chemical and Process Engineering solution from the Chemical and Process Process Flow Diagram Symbols ConceptDrawThe ball mill modelling process is described as the point where the feed entering the distribution size is coarse, and where there is an overflow and discharge of the mill, the distribution size New approach to ball mill modelling as a piston flow

New approach to ball mill modelling as a piston flow

In this case, the piston flow was introduced for a more realistic process The ball mill modelling process is described as the point where the feed entering the distribution size is coarse, and where there is an overflow and discharge of the mill, the distribution size is fine and equivalent to the product distribution size The ball mill modelling process is described as the point where the feed entering the distribution size is coarse, and where there is an overflow and discharge of the mill, the distribution size is fine and equivalent to the product distribution size In this work, the evolution of the size of particles along the mill piston flow process was studiedNEW APPROACH TO BALL MILL MODELLING AS A Influence of roller and ball mill grinding technology applied for sucrose particles in a lipophilic suspension was investigated considering both particle properties and suspension's flow behaviorImproving particle size distribution and flow

Ball Mills an overview ScienceDirect Topics

A ball mill is a type of grinder used to grind and blend bulk material into QDs /nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shellNew approach to ball mill modelling as a piston flow process By Eduard Guasch Cascallo, Hernán Francisco Anticoi Sudzuki, Sarbast Hamid, Josep Oliva Moncunill, María Pura Alfonso Abella, Teresa Escobet Canal, Lluís Sanmiquel Pera and Marc Bascompta MassanesNew approach to ball mill modelling as a piston flow 2 Description of the Ball Mill Grinding Process The ball mill grinding process we studied is shown in Fig1, and its operation is as follows The fresh ore feed into a ball mill for grinding with the water fed to control the mill slurry concentration Then the discharge slurry from the mill pours into a LNCS 4491 Hybrid Intelligent Modeling Approach for

New approach to ball mill modelling as a piston flow

New approach to ball mill modelling as a piston flow process By Eduard Guasch Cascallo, Hernán Francisco Anticoi Sudzuki, Sarbast Hamid, Josep Oliva Moncunill, María Pura Alfonso Abella, Teresa Escobet Canal, Lluís Sanmiquel Pera and Marc Bascompta MassanesThe vector stencils library "Industrial equipment" contains 81 symbols of pumps, compressors, fans, turbines, and power generators Use these shapes to design pumping systems, air and fluid compression systems, and industrial process diagrams in the ConceptDraw PRO software extended with the Chemical and Process Engineering solution from the Chemical and Process Engineering area of ConceptDraw Process Flow Diagram Symbols ConceptDrawImproving particle size distribution and flow properties of milk chocolate produced by ball mill and blendingImproving particle size distribution and flow

Fluid mechanics of slurry flow through the grinding

@article{osti, title = {Fluid mechanics of slurry flow through the grinding media in ball mills}, author = {Songfack, P K and Rajamani, R K}, abstractNote = {The slurry transport within the ball mill greatly influences the mill holdup, residence time, breakage rate, and hence the power draw and the particle size distribution of the mill productThe invention relates to a dispersing process in which a mill base consisting of solids and of a liquid phase is conveyed through a stirred ball mill containing a grinding medium, energy is supplied in this stirred ball by rotating rotors, and the solids are dispersed, and wet with the liquid phase, wherein the rotors rotate at such a high speed that the grinding medium moved by them forms, as Dispersing process and stirred ball mill for carrying Main equipment: LM170K vertical mill; Process Flow Of Gypsum Grinding Line LM vertical roller mill a comprehensive, largescale grinding equipment that integrates the five functions of crushing, grinding, powder selection, drying, and material conveying The LM vertical mill integrates crushing, drying, grinding, powder selection, and conveyingProcess Flow Of Gypsum Grinding Line

Grinding control strategy on the conventional milling

(9 mm) is fed to the rod mill, and the water is fed in ratio to the ore feed mass The rod mill discharge is pumped, without any further water addition, to the first ball mill The ball mill discharges to a sump where water is added before the slurry is pumped to the first cyclone (Cylcone 1) See Figure 1 for a schematic of the process flowMills and grinders for pellet press applications These allow homogenous KBr powder preparation for analysis such as FTIR transmission and diffuse reflectanceMills and Grinders SpecacChemical and Process Engineering Solution from the Industrial Engineering Area of ConceptDraw Solution Park is a unique tool which contains variety of predesigned process flow diagram symbols for easy creating various Chemical and Process Flow Diagrams in ConceptDraw PRO Mill Process Flow Diagram Symbols Industrial equipment

HIGH INTENSITY GRINDING ISSUE 32 AT ITS FINEST

As the flow transfers upwards, the ore slurry passes through the rotating discs and the free space between the static counter discs lining the wall (see Fig 2) Due to the vertical arrangement of the mill, classification is conducted simultaneously throughout the grinding process with larger particles remaining longer at the peripheral,New approach to ball mill modelling as a piston flow process By Eduard Guasch Cascallo, Hernán Francisco Anticoi Sudzuki, Sarbast Hamid, Josep Oliva Moncunill, María Pura Alfonso Abella, Teresa Escobet Canal, Lluís Sanmiquel Pera and Marc Bascompta MassanesNew approach to ball mill modelling as a piston flow High efficient dry process cement ball mill 1 Usage of cement ball mill: Cement ball Mill is mainly used for grinding various cement clinker or other materials in building China High Efficient Dry Process Cement Ball Mill

Modelling of the HighEnergy Ball Milling Process

In this paper, the milling parameters of high energy ball mill (Fritsch Pulverisette 7) like vial geometry, number and size of balls and speed of the mill were modelled and discussed Simulations through discrete element method (DEM) provide correlation between the milling parameters A mathematical model is used to improve and develop this processThe vector stencils library "Industrial equipment" contains 81 symbols of pumps, compressors, fans, turbines, and power generators Use these shapes to design pumping systems, air and fluid compression systems, and industrial process diagrams in the ConceptDraw PRO software extended with the Chemical and Process Engineering solution from the Chemical and Process Engineering area of ConceptDraw Process Flow Diagram Symbols ConceptDrawChocolate mass is produced by roller refining and conching or alternatively by ball milling Grinding can generate varying particle size distributions (PSD), which again influence flow parameters The latter are very important for downstream processing as well as mouthfeel and consumer acceptance of the final product The objective of the work was to influence and control PSD and flow Improving particle size distribution and flow

Dispersing process and stirred ball mill for carrying

The invention relates to a dispersing process in which a mill base consisting of solids and of a liquid phase is conveyed through a stirred ball mill containing a grinding medium, energy is supplied in this stirred ball by rotating rotors, and the solids are dispersed, and wet with the liquid phase, wherein the rotors rotate at such a high speed that the grinding medium moved by them forms, as (9 mm) is fed to the rod mill, and the water is fed in ratio to the ore feed mass The rod mill discharge is pumped, without any further water addition, to the first ball mill The ball mill discharges to a sump where water is added before the slurry is pumped to the first cyclone (Cylcone 1) See Figure 1 for a schematic of the process flowGrinding control strategy on the conventional milling Mills and grinders for pellet press applications These allow homogenous KBr powder preparation for analysis such as FTIR transmission and diffuse reflectanceMills and Grinders Specac

HIGH INTENSITY GRINDING ISSUE 32 AT ITS FINEST

As the flow transfers upwards, the ore slurry passes through the rotating discs and the free space between the static counter discs lining the wall (see Fig 2) Due to the vertical arrangement of the mill, classification is conducted simultaneously throughout the grinding process with larger particles remaining longer at the peripheral,Chemical and Process Engineering Solution from the Industrial Engineering Area of ConceptDraw Solution Park is a unique tool which contains variety of predesigned process flow diagram symbols for easy creating various Chemical and Process Flow Diagrams in ConceptDraw PRO Mill Process Flow Diagram Symbols Industrial equipment