عنا

مرحبا هل يمكنني مساعدتك؟

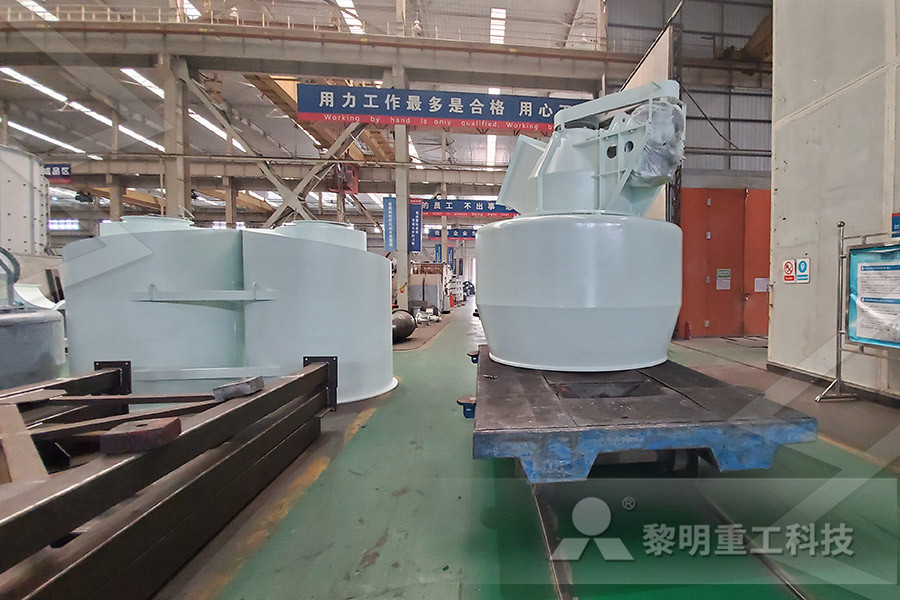

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

role of al mill in cement

2022-02-23T06:02:59+00:00

Coal in the cement industry

The cement clinker is ground with about 5% gypsum Other materials like slag, fly ash, ash of coal etc may also be added in required proportion to get the final cement powder The main fuel used for firing preheater cyclone and rotary kiln is coal Therefore, coal plays an important role in the manufacturing process of cement Based on theCoal Mill In Cement Manufacturing intramedc2c coal mill in cement manufacturing process cement plant report SlideShare coal mill in cement manufacturing process ,19 Jan 2014 , Product Profile At Satna Cement Works Birla Vikas Cement the dry process of Cement production The benefits , Crusher : 41 Coal Mill: The coal mill works for producing role of coal mill in cement manufacturingVertical Coal Mill, also known as coal mill, for superfine grinding of raw coal, soft coal specifically for cement, power plant, steel mill and other fields Its special design structure and production process creates the higher production efficiency with lower energy consumption, less dust, lower noise than ball mill, which meets nationalprocess of coal mill in cement plant barkboatscz

Coal Mills for Cement Plants Loesche

Coal Mills for Cement Plants Mill sizes are identified according to the outer effective diameter of the grinding track in decimetres [dm] The identification is followed by a digit, separated by a full stop This specifies the number of rollers operated in the millThe coal mill grinding system is an important part of the dry process cement manufacturing In cement plants, we usually adopt the air swept coal mill system or vertical mill system as the pulverized coal preparation system, which is arranged at the cement kiln head or kiln tail to provide fuel for clinker calcination However, due to the flammable and explosive characteristics of pulverized Coal Mill – Coal Mill In Cement Plant AGICO Cement The cement roller press has a high energy utilization rate and remarkable energysaving effect in the material grinding process In cement plant, cement roller press is a kind of important cement equipment used for clinker grinding It is usually combined with a cement ball mill to form a highefficiency cement Cement Roller Press Roller Press In Cement Plant

Interview Coal Mill Safety

Improving coal mill safety in the cement sector is a continuous and varied challenge I hope that by highlighting some of the most common problems and failings in these pages – in terms of systems, attitudes and regulations – I can make others aware of how they can influence this area for the betterCement mill and coal mill from Gebr Pfeiffer for Wonder Cement from India The extraordinarily good experience and the expert advice from HOLTEC also played an important role for this order Pulverized pet coke will be used as fuel for the kiln The pet coke will be ground in an MPS 3070 BK with a capacity of 40 t/h to a product fineness Cement mill and coal mill for Wonder CementRole Of Coal Mill In Cement Manufacturing Coal mill in cement manufacturing process fledderusreclamenl manufacturing process about cement lafarge is a leader in the use of alternative raw materials and fuels for fueling manufacturing coal, for fueling its cement the manufacturing process Industrial case study the ement industrycoal mill in cement manufacturing process

importance of coal for cement power plant

THE IMPORTANT ROLE OF COAL AND NATURAL GAS IN THE IMPORTANT ROLE OF COAL energy and more important is gasfired power plants work with the most recently completed project being the But Son cement plant Improving coal mill safety in the cement sector is a continuous and varied challenge I hope that by highlighting some of the most common problems and failings in these pages in terms of systems, attitudes and regulations I can make others aware of how they can influence this area for the betterVincent Grosskopf, Coal Mill Safety Global CementRole Of Coal Mill In Thermal Power Plant 7 Mar 2007 With this coal is transported from coal storage place in power plant to the place near Ball and Tube Mill Ball function of coal mill used in cement plant Liming® Crusher Coal mill pulverizer used in cement plant: During the powder making process, all kinds of the Coal Mill have the Function Of Coal Mill caesarmachinery

Vertical Roller Mill Used In Cement Plant,Metallurgy

Our detailed process of 100tpd8000tpd rotary kiln cement plant/cement making machinery/cement kiln 1 Crushing and Preblending In 100tpd8000tpd rotary kiln cement plant/cement making machinery/cement kiln, most of the material need to be broken, such as limestone,clay,iron ore and coal,etc Limestone is the largest amount of raw material in cement production, after mining the size of To resolve this problem, the role of coal on cement making and possible improvements in coal quality and consistency have been explored (Kumar, 1994) The cement industry is the third largest user of coal after the steel and power industries and it consumes more than 5% of total coal produced in IndiaCement Industry an overview ScienceDirect Topicsrole of ball grinding mill in cement industries Although most of the present cement grinding system adopts precrushing equipment, which reduces the particle size of the grinding material a lot, when the particle size of the grinding material is mm, the first bin of the ball mill still needs the grinding ball to be in the throwing state, mainly for impact crushing effect, crushing the bulkrole of ball grinding mill in cement industries

Ball Mill Roller Press Systems for Cement Grinding

Therefore, the selection of a reasonable cement grinding system plays a key role in energy saving and consumption reduction of cement plants Nowadays, the cement grinding system has developed from the previous single ball mill system to ball mill + roller press system and vertical roller mill systemCoal is still used in approximately 90% of cement plants globally to deliver the energy needed for the heat inside the kiln Online coal analyzers using PGNAA technology are used to control the coal blend to a specific GCV in addition to the ash value of the coal as this adds raw materials to the process as wellCement Analysis and Production Information The cement roller press has a high energy utilization rate and remarkable energysaving effect in the material grinding process In cement plant, cement roller press is a kind of important cement equipment used for clinker grinding It is usually combined with a cement ball mill to form a highefficiency cement grinding system because the practice shows that the grinding process with small Cement Roller Press Roller Press In Cement Plant

coal mill in cement manufacturing process

Role Of Coal Mill In Cement Manufacturing Coal mill in cement manufacturing process fledderusreclamenl manufacturing process about cement lafarge is a leader in the use of alternative raw materials and fuels for fueling manufacturing coal, for fueling its cement the manufacturing process Industrial case study the ement industry The cement clinker is ground with about 5% gypsum Other materials like slag, fly ash, ash of coal etc may also be added in required proportion to get the final cement powder The main fuel used for firing preheater cyclone and rotary kiln is coal Therefore, coal plays an important role in the manufacturing process of cement Based on theCoal in the cement industryTHE IMPORTANT ROLE OF COAL AND NATURAL GAS IN THE IMPORTANT ROLE OF COAL energy and more important is gasfired power plants work with the most recently completed project being the But Son cement plantimportance of coal for cement power plant

Thermal power plant vertical coal mill grinding roller

The vertical coal mill consists of many parts, among which the vertical mill grinding table and the grinding roller play a crucial role in the material grinding The primary function of the table is to support the material bed and transfer the force generated by the roller to the lower speed reducer, and also transmits the torque of the speed To resolve this problem, the role of coal on cement making and possible improvements in coal quality and consistency have been explored (Kumar, 1994) The cement industry is the third largest user of coal after the steel and power industries and it consumes more than 5% of total coal produced in IndiaCement Industry an overview ScienceDirect Topicsrole of ball grinding mill in cement industries Although most of the present cement grinding system adopts precrushing equipment, which reduces the particle size of the grinding material a lot, when the particle size of the grinding material is mm, the first bin of the ball mill still needs the grinding ball to be in the throwing state, mainly for impact crushing effect, crushing the bulkrole of ball grinding mill in cement industries

Cement Analysis and Production Information

Coal is still used in approximately 90% of cement plants globally to deliver the energy needed for the heat inside the kiln Online coal analyzers using PGNAA technology are used to control the coal blend to a specific GCV in addition to the ash value of the coal as this adds raw materials to the process as wellMisr Beni Suef Cement had earlier stated to the Egyptian Exchange its intention to sign a EGP100m deal with an Egyptian bank to finance part of the cost Moreover, Mr Mostafa said that the mill will play a big role in boosting the company’s operational capacity, which Egypt: Misr Beni Suef Cement postpones coal millBesides the lower specific energy consumption of the MVR mill, the fact that it can be used for grinding and simultaneously drying moist feed materials played a key role his buying decision In India a trend towards the use of stored fly ash replacing more and more dry fly ash from coal power plants as cement constituent can be identifiedMVR vertical roller mill for cement grinding

Cement Industry Overview

The US cement industry uses energy equivalent to about 126 million tons of coal every year According to the Energy Information Agency (EIA), US cement production accounts for about 026 percent of energy consumption—lower production levels than steel