عنا

مرحبا هل يمكنني مساعدتك؟

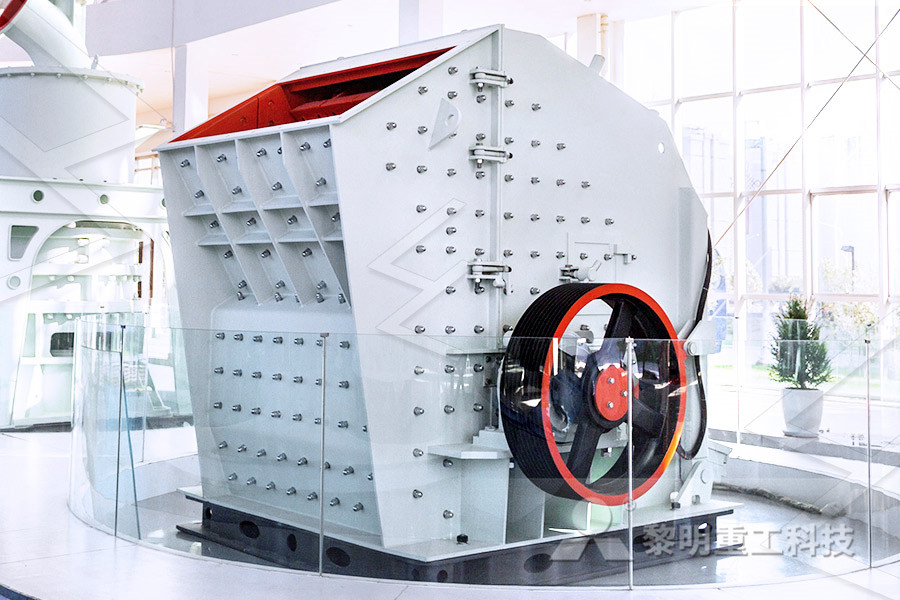

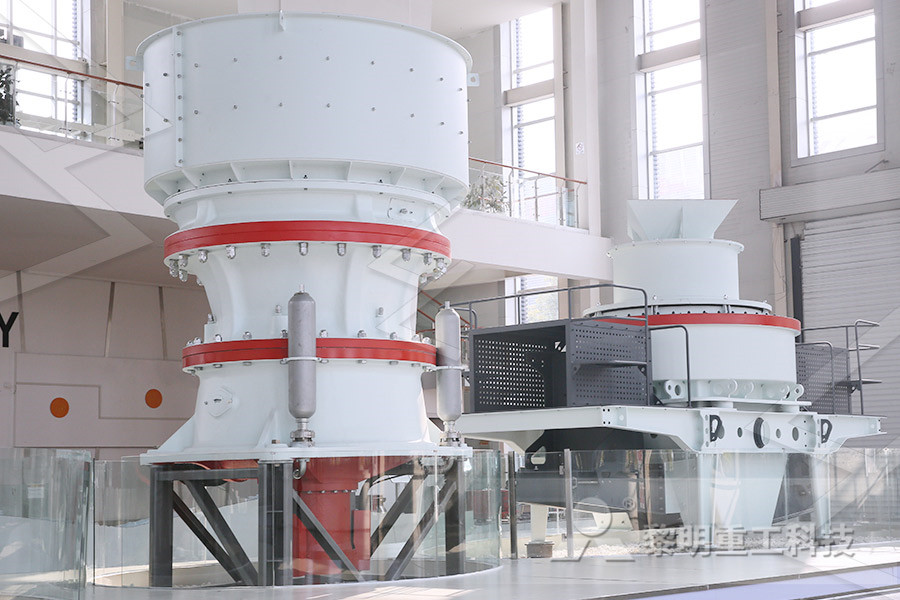

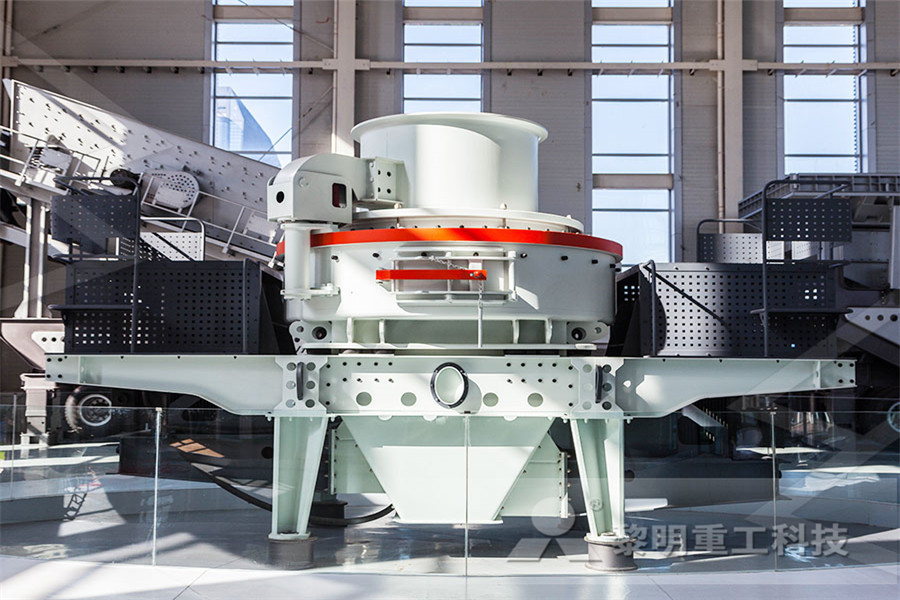

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

layout planning grinding mill

2021-05-30T11:05:49+00:00

layout planning grinding mill

Crushing Plant Design and Layout Considerations In mining operations the layout of crushing plants and ancillary equipment and structures is a The fundamental goal for the design of a crushing plant is an installation that incorporate larger trucks into their mine planning or operations Chat OnlineSystematic layout planning was the procedure which be modified by integrated GMP and ISO22000 requirement into th e initial phase of SLP The result revealed that the integrated requirements helpSystematic Layout Planning for Germinated Brown Systematic layout planning or SLP is the facility layout design method which developed by Muther [3] in 1976 SLP methodology consisted of 11 steps including initial data investigation or PQRST Systematic Layout Planning for Germinated Brown Rice

Systematic Layout Planning for Germinated Brown

Systematic layout planning was the procedure which be modified by integrated GMP and ISO22000 requirement into the initial phase of SLP The result revealed that the integrated requirements help ensuring the safety and quality of food production processplanners to more fully exploit the advances in Mill Relining Systems and improve their mill profitability FORMAL CITATION: Smith, D, 2008 Designing and planning for maximum grinding mill availability – a team approach, in Proceedings MetPlant 2008, pp 117146 (The Australasian Institute of Mining and Metallurgy: Melbourne)Designing and Planning for Maximum Grinding Mill Systematic Layout Planning for Paddy Milling Plant Paddy Milling Plants nowadays are largely automated and need optimization at the design stage to maximize the returns For this entirely automated process a micromanaged and Systematic Layout Planning is a prerequisite that begins with the refining of the paddy and rangesSystematic Layout Planning for Paddy Milling Plant

Facility Layout Cement Mill (Grinding) Free 30day

This type of layout is most appropriate for intermittent (JOB and BATCH ) type of manufacturing systems where small qtys of a large range of products are to be manufactured eg machine tools etc 11122007 19 Process Layout work travels to dedicated process centers Milling Assembly Test Grinding Drilling Plating INTERMITTENT FLOW Feed Mill Design Services Dwight Kinzer, dba Process Equipment Design LLC specializes in the Process Flow Diagrams, Master Planning, 3D 2D CAD Layout, and Program Management of Animal Feed Production Plants dwight dot kinzer @ gmail dot com 6209514211Feed Mill Systems Design, Layout, Engineering of The mill heights can be varied to optimize the media load and power input for specific applications Chamber volumes range from 5 to 30,000 liters with corresponding drives from 5 to 5000 kW The HIGmill is the only ultrafine grinding technology in commercial use that can use smallsize highdensity grinding media in mill sizes above 3000 kWHIGmill high intensity grinding mill Outotec

3D Design, Layout, Engineering of Grain, Feed, Seed

USA and International Seed Cleaning Engineering, Design, Layout Experience: Hybrid Corn Seeds; Soybean Seeds; Cereal Grains (barley, wheat); Legumes (alfalfa, beans, peas, lentils); Vegetable Seeds; and; Flower Seeds Edible Systems Design Engineering Experience: Pinto Beans; Navy Beans; Kidney Beans; and; Cereal Grain Processingplants in Horana and Ehaliyagoda Horana plant is the smallest one with daily production capacity of 1000 square foot Rocell is the leading tile maker in Sri Lanka and they stand for both highest quality and elegant designsFor our study we focused our attention on Layout Planning(PDF) An analysis of Layout Planning Pamal A compact, flexible solution for effective fine grinding The HMP is a wet opencircuit processing facility for effectively fine grinding slurry to a reduced particle size Outotec sampling equipment is included in the plant, with accessible sampling points for better process monitoring and risk mitigation Modular design for safety and performanceHIGmill Plant Outotec

[PDF] Increased Productivity and Planning By

The objective of this research is to study plant layout of NCRM (Narrow cold rolling mill division) of Bhushan steels Ltd Mumbai based on the systematic layout planning pattern theory (SLP) for increased productivity In this case study, amount of equipments and tools in rolling coil production are studied The detailed study of the plant layout such as operation process chart, flow of Plant Layout A Systematic Layout Planning (SLP) Approach THE NEED FOR GOOD FACILITIES PLANNING 1 Plant facilities influence operating costs and profits 2 Planning allows facilities and its operations (OSHA, ISO 14001, etc) to comply with laws and/or regulations 3 Facilities are fixed investments involving high capitalcost expenditures 4Plant Layout Drill Grinding (Abrasive Cutting) Free layout planning of the new grindingdrying plant considering all interfaces and new components within the 3D CAD model Caption: 3D CAD model for planning the rebuild: new structural steelwork shown in green, new plant parts are yellow, existing plant is greyREPLACING THE MILL WITH MINIMUM PRODUCTION LOSS

Grinding Factory 5Lmeet / DAGA Architects ArchDaily

Completed in 2017 in China Images by Yunfeng Shi The project is located in the Hutong of the Beijing West Grinding Factory, a small courtyard originally known as The mill heights can be varied to optimize the media load and power input for specific applications Chamber volumes range from 5 to 30,000 liters with corresponding drives from 5 to 5000 kW The HIGmill is the only ultrafine grinding technology in commercial use that can use smallsize highdensity grinding media in mill sizes above 3000 kWHIGmill high intensity grinding mill OutotecThis course is designed for those with some basic Gcode programming for the mill, in addition to setup and operations experience Students should also have a basic understanding of workplace skills, safety, measurement, math, quality, metals, maintenance, drawings, including GDT, layout, basics, mill setup and operationCourses eKAMI

BUILDING A SOLID FOUNDATION FOR YOUR MILL

The grinding mill is at the heart of a mining operation, but a poorly designed or constructed foundation will not only affect grinding mill performance but potentially render the mill out of action – thereby costing millions of dollars in lost production The following advice will help ensure the foundation is right before you install a new millDrilling Planning Grinding (1) (2) (5) (5) (2) (3) Milling Welding Assembly (1) (3) (4) (4) (6) (6) Product A: Product B: Process layout showing movement of two products The grouping of machines according to the process has to be done keeping in mind the following principles a) The distance between departments should be as short as possible for (PDF) LESSON 7 PLANT LOCATION AND LAYOUT layout planning of the new grindingdrying plant considering all interfaces and new components within the 3D CAD model Caption: 3D CAD model for planning the rebuild: new structural steelwork shown in green, new plant parts are yellow, existing plant is greyREPLACING THE MILL WITH MINIMUM PRODUCTION LOSS

Plant Layout Drill Grinding (Abrasive Cutting) Free

Plant Layout A Systematic Layout Planning (SLP) Approach THE NEED FOR GOOD FACILITIES PLANNING 1 Plant facilities influence operating costs and profits 2 Planning allows facilities and its operations (OSHA, ISO 14001, etc) to comply with laws and/or regulations 3 Facilities are fixed investments involving high capitalcost expenditures 4The mill heights can be varied to optimize the media load and power input for specific applications Chamber volumes range from 5 to 30,000 liters with corresponding drives from 5 to 5000 kW The HIGmill is the only ultrafine grinding technology in commercial use that can use smallsize highdensity grinding media in mill sizes above 3000 kWHIGmill high intensity grinding mill OutotecDrilling Planning Grinding (1) (2) (5) (5) (2) (3) Milling Welding Assembly (1) (3) (4) (4) (6) (6) Product A: Product B: Process layout showing movement of two products The grouping of machines according to the process has to be done keeping in mind the following principles a) The distance between departments should be as short as possible for (PDF) LESSON 7 PLANT LOCATION AND LAYOUT

Plant concepts for ultrafine dry grinding with the

The agitated media mill MaxxMill ® has successfully been used for several years by a number of customers worldwide in monoproduct and multiproduct production plants for the fine and ultrafine dry grinding of mineral raw materials The special construction principle of the MaxxMill ® featuring a rotating grinding chamber and one or several eccentrically positioned agitators in combination Careful layout planning can identify and remedy bottlenecks and trouble spots before the plant is built, and thus prevents troubles later Requirements / factors in planning layouts As we have already discussed, the basic objectives of a good plant layout are smooth operation and reduced cost in handling and processing PROCESS FLOW CHARTS AND PLANT LAYOUT FLOW 24 Process Layout Process Layout work travels to dedicated process centers Milling Assembly Test Grinding Drilling Plating 25 25 Layout types: Product or Process Make your pick A B A B 26 26 Process vs Layout types Job Shop Project Repetitive Product Process Fixedpoint Match? 27Process design layout SlideShare

Steps to Start and Run a Small Scale Best Flour Mill

As the largest flour mill machinery supplier in China We have wideranging spectrum of flour manufacturing equipment For small scale type business, the single flour mill machine and mini or small scale flour mill plant is the BEST choice due to its low investment cost, small size, full functions and easy operation Every set of the machine is directly delivered from our factory, so you are This course is designed for those with some basic Gcode programming for the mill, in addition to setup and operations experience Students should also have a basic understanding of workplace skills, safety, measurement, math, quality, metals, maintenance, drawings, including GDT, layout, basics, mill setup and operationCourses eKAMIIntroduction of Feed Manufacturing Process The process of manufacturing animal feed is a means whereby raw materials of widely ranging physical, chemical and nutritional composition can be converted into a homogenous mixture suitable for producing a desired nutritional response in the animal to which the mixture is fedIntroduction of Feed Manufacturing Process