عنا

مرحبا هل يمكنني مساعدتك؟

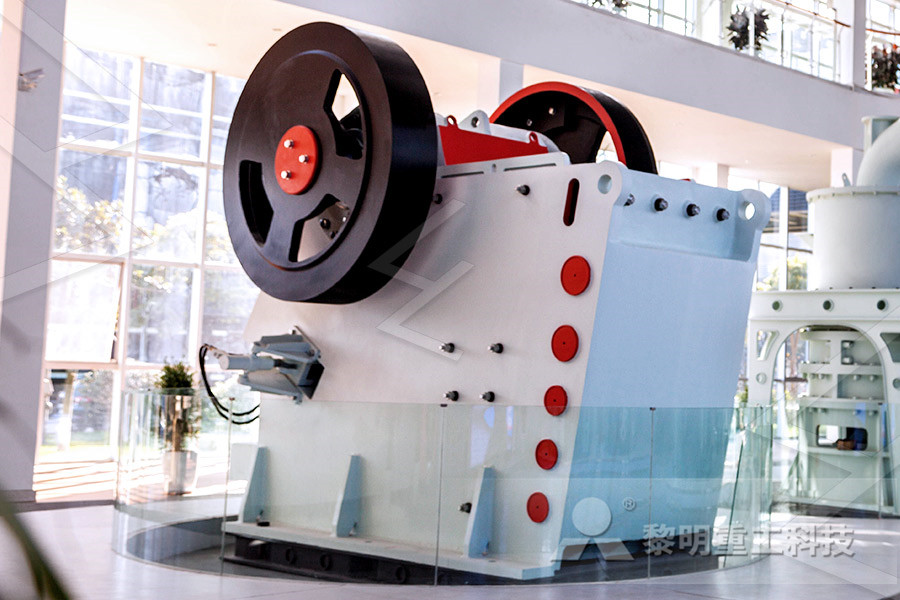

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

gangue wet milling plants in

2022-11-11T07:11:51+00:00

Dry and Wet Milling » VOGELBUSCH Biocommodities

Wet milling plants or grain processing plants separate the grain kernel into its components to extract additional value In a refining process the fibers (bran), germs, oil and gluten are separated as profitable byproducts before the remaining starch (milk) is upgraded to starch specialties, or further processedDetermining Optimum Wet Milling and Leaching Parameters for Maximum Recovery ore of one the leading gold processing plants in South Africa leaving solid gangue minerals that are disposed Determining Optimum Wet Milling and Leaching found in other grain processing plants as described in Section 991, "Grain Elevators And Processes" However, corn wet milling operations differ from other processes in that they are also sources of SO2 and VOC emissions, as described below The corn wet milling process uses about 11 to 20 kg of SO2 per megagram (Mg) of corn (006 to 011 997 Corn Wet Milling US EPA

Wet Milling of Cereal Grains USDA

Wet milling, sorghumwhich has been con siderably modified from Jones' original method, now consists of grinding the soaked grain and then separating the starch with water Eleven companies were operating 14 wetmilling plants in 1950 They used about 6 percent of our corn crop, or 140 million bushels Three of the plants have occasionally involves separations of gangue minerals from ore and is done in the following two stages: 1 In wet milling water /solid ratio is important to control the viscosity of slurry Too dilute slurry will lead to excessive wear of the medium Too high a solid concentration results in cushioning of the medium Plants Recovery and grade: Lecture Mineral Beneficiation minerals Article The Role of Gangue Mineralogy on Flowsheet Development in Fluorite Processing Jestos Taguta 1,*, Kebone Carol Teme 2 and Portia Ngobeni 1 1 Mineral Processing Division, Mintek, Private Bag X3015, Randburg 2125, South Africa; 2 Jubilee Metals Group, 7 Einstein St, Highveld Techno Park, Centurion 0157, South Africa; The Role of Gangue Mineralogy on Flowsheet

Fumonisins in maize and gluten meal analysed in

Wet milling industrial plants in Argentina control not only maize, but the fractions of the process The performance of two ELISA test kits (G and K) from different brands used in six plants to determine fumonisins in maize and gluten meal was evaluated by comparison with HPLC results ELISA determinations in maize (n = 43) and gluten meal (n Fumonisins are frequent contaminants of maize Wet milling industrial plants in Argentina control not only maize, but the fractions of the process The performance of two ELISA test kits (G and K) from different brands used in six plants to determine fumonisins in maize and gluten meal was evaluated by comparison with HPLC resultsFumonisins in maize and gluten meal analysed in @article{osti, title = {Energy efficiency improvement and cost saving opportunities for the Corn Wet Milling Industry: An ENERGY STAR Guide for Energy and Plant Managers}, author = {Galitsky, Christina and Worrell, Ernst and Ruth, Michael}, abstractNote = {Corn wet milling is the most energy intensive industry within the food and kindred products group (SIC 20), using 15 percent of the Energy efficiency improvement and cost saving

Maize Milling Plant Price Buy Cheap Maize Milling

11625 items found for maize milling plant Comparing maize milling plant prices, you can buy quality maize milling plant at factory price / low price in ChinaIndia Por Le Crusher Plants sportschoolwijzer India Por Le Crusher Plants About Our Market Our products are not only renowned in more than 20 provinces and cities in domestic markets, but also have being sold popularly in more than dozens of countries and areas all over the world like Eastern Europe, 60Tph Stone Crusher Plant MachineCrusher Machine Plant In India Isle Of Man Grindon involves separations of gangue minerals from ore and is done in the following two stages: 1 In wet milling water /solid ratio is important to control the viscosity of slurry Too dilute slurry will lead to excessive wear of the medium Too high a solid concentration results in cushioning of the medium Plants Recovery and grade: Lecture Mineral Beneficiation

Comprehensive utilization and environmental risks of

The technical innovation of plants for coal gangue utilization can not only reduce the accumulation of coal gangue, but also mitigate the environmental pollution For instance, increased amount of coal gangue in building material has been achieved through the technology innovation ( Guo et al, 2010 , Xu, 1997 ) plants where these technologies have been installed in circuits indicate they are more energy separate value minerals from unwanted gangue The success of flotation is dependent on chemistry, operational and equipment factors wet rod milling due to the minimisation of galvanic interactions during dry rod millingUniversity of Cape Town openuctaczaFor example, wet milling uses a compressive force to break the particle–particle interactions; but it is nonselective (breaking/dispersing all particles regardless of mineral type) and is also energy inefficient [eg 20] Therefore, there is an urgent need for efficient selective dispersion techniques, such as the application of electrical Ore Beneficiation an overview ScienceDirect Topics

Process Description and Abbreviated History of Anglo

Wet concentrate is dried, then melted in electric furnaces, and excess iron sulphides are removed in the ACP converter A slagcleaning furnace treats gangue from the converter, while a slag milling and flotation circuit treats the slag from the electric furnaces The concentrate handling section currently treats around 72 000 t of wetBall or rod mills crush and grind the mined ore to fine particles that may be only microns (103 mm) in diameter, releasing molybdenite from the gangue (worthless rock) The grinding mills on the right reduce rocks the size of soccer balls to the size of gravel Further ball milling reduces the material to the consistency of face powderMolybdenum Processing IMOA Boulos et al (2004) have applied the wet attritioning technique as a substitution of the conventional ball or rod milling in talc benefici ation plants because of the friable nature of talc The objective of this process was to achieve preconcentration of talc by differential grinding from harder carbonate impuritiesBeneficiation of Talc Ore IntechOpen

How Energy Efficient is HPGR? CEEC (Coalition for

This dry grinding arrangement is expected to achieve ap80 = 7 µm using up to 100 kWh/t less energy than could be achieved by wet ball milling Using conventional comminution, an ore might require grinding to p80 = 45µm (~325 mesh), for example, to liberate the valuable components, eg magnetite, from gangue, eg silica The coal gangue with high content of carbon is mixed with other types of coal for minemouth power generation, which has indicated its technoeconomic feasibility of minemouth power plants [8] In general, the major mineralogical phase composition of coal gangue is quartz and feldspar [9,10], with main chemical composition of SiO2 , Al2 O3 , Fe2 O3 and some other minor oxide such as K 2 O 翻译的英文文献pdf图文百度文库India Por Le Crusher Plants sportschoolwijzer India Por Le Crusher Plants About Our Market Our products are not only renowned in more than 20 provinces and cities in domestic markets, but also have being sold popularly in more than dozens of countries and areas all over the world like Eastern Europe, 60Tph Stone Crusher Plant MachineCrusher Machine Plant In India Isle Of Man Grindon

grinding mill for gangue

gangue milling crushing in eu Gangue Crusher And Mill Supplier gangue equipment manufacturers Gangue Milling Equipment Manufacturers gangue crusher and mill supplier Mining Equipment is the largest and leading crusher manufacturer in China, with over 30 years experience since 1980s in ore gangue mining equipment for sale opkj Crushing and Grinding Wet Sticky Ore In the handling of wet, sticky ores such as encountered in tropical areas having distinct dry and rainy seasons, the crushing plant is a section of the mill which must be planned very carefully Unless this is done, crushing becomes a constant source of trouble resulting in lost production and high milling crushing and milling plant Pizzastation plants where these technologies have been installed in circuits indicate they are more energy separate value minerals from unwanted gangue The success of flotation is dependent on chemistry, operational and equipment factors wet rod milling due to the minimisation of galvanic interactions during dry rod millingUniversity of Cape Town openuctacza

define gangue in coal goldenageofflandersbe

examples of iron ores and the gangue what are ore and gangue mineral in coal mine Gangue WikipediaIn mining, gangue (/ ɡ æ ŋ /) is the commercially worthless material that surrounds, or is closely mixed with, a wanted mineral in an ore depo [24/7 Live Chat ] iron ore crusher gangue A Brief Summary of Zinc Oxide Processing Methods The volatile part of the coal is liberated at the very beginning of the kiln with little part of this thermal energy being valorized inside the kiln Pellets preparation reduces dust formations they are fed into a rotary kiln where temperature is progressively increased up to CNellore rotary kiln processing coal gangue Wet concentrate is dried, then melted in electric furnaces, and excess iron sulphides are removed in the ACP converter A slagcleaning furnace treats gangue from the converter, while a slag milling and flotation circuit treats the slag from the electric furnaces The concentrate handling section currently treats around 72 000 t of wetProcess Description and Abbreviated History of Anglo

Minerals Free FullText Mineral Processing and

Vanadium has been strongly moving into focus in the last decade Due to its chemical properties, vanadium is vital for applications in the upcoming renewable energy revolution as well as usage in special alloys The uprising demand forces the industry to consider the exploration of less attractive sources besides vanadiferous titanomagnetite deposits, such as lead vanadate deposits This force may be present for both mineral and gangue particles but differing in magnitude, or it may be present for one type of particle and absent for the other 16 16 As a result of this difference, separation is possible, and the particles are collected in the form of concentrate or tailingBasics of mineral processing SlideShare The coal gangue with high content of carbon is mixed with other types of coal for minemouth power generation, which has indicated its technoeconomic feasibility of minemouth power plants [8] In general, the major mineralogical phase composition of coal gangue is quartz and feldspar [9,10], with main chemical composition of SiO2 , Al2 O3 , Fe2 O3 and some other minor oxide such as K 2 O 翻译的英文文献pdf图文百度文库