عنا

مرحبا هل يمكنني مساعدتك؟

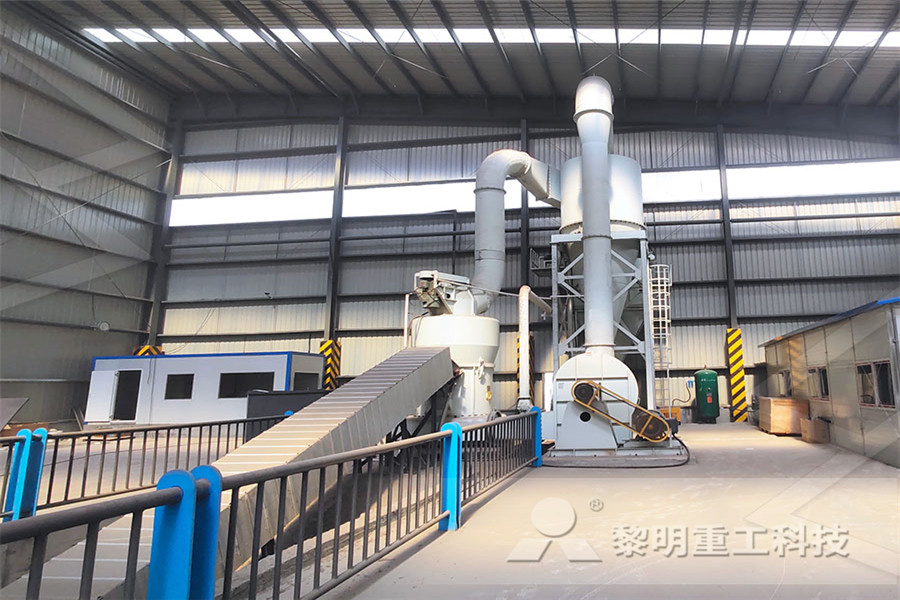

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

how to design surge bin capacity

2021-12-02T00:12:07+00:00

Design of Mineral Sand Surge Bin to deliver consistent

In order to design the bin with the appropriate hopper angles to achieve massflow, flow property testing was undertaken on the mineral sand slurry utilising a Jenike shear tester with the test cell submerged to simulate conditions within the surge bin as shown in Figure 1 The design 1 The purpose of a surge bin between two machines is to permit either of the two machines to continue production for at least some of the time while the other machine is interrupted by break down or by preventive maintenance or by other problems up or down the line This results in a higher capacity than would have been possible without a surge binHow to Calculate the Size of Surge BinsAbstract The logistics transportation system with surge links is widely used in mines, power plants, material yards; and etc Bin capacity size in surge links has great influence on reliability and production efficiency of whole logistics transportation systemStudy of Integrated Design Processing Methods of

Surge Bins for Bulk Material Processes National Bulk

For surge bin specifications that necessitate engineeredtoapplication design and construction, NBE ETA project delivery will ensure the design, construction, and integration of surge bin systems specific to the most demanding application requirements Standard quantity and location of view windows depends on surge bin capacity High and Design of Mineral Sand Surge Bin to deliver consistent Lyons J, Hill G, Vadeikis C, Wiche S Innovative Surge Bin Design for Mineral Sands Processing Plant, Recent Advances in Mineral Processing Plant Design Tucson 2009 Historically, mineral sand surge bins were designed without considering the mode of flow within the binMineral Processing Surge Bin DesignSurge Bin Design Large capacity surge bin mining nldcindiain surge bin in coal mine design More About surge bin designs mining Please The system Hyder worked on consisted of a 500 tonne capacity surge bin surge bin designs mining coal russian viewchannelmx surge bin design May 18 2013 A key component was Mineral Technologies innovative surgeSurge Bin In Coal Mine Design espacekuglerch

Eleven Ways to Transform Surge Capacity in the

1 Collaboration for surge A 2007 review of INGO surge capacity led by People In Aid for Emergency Capacity Buliding (ECB) recommended increasing surge collaboration across the sector Almost ten years on, collaboration is still fragmented and the greatest progress has in Funnel Flow bin : the discharge of the product at the center of the bin will be promoted, a funnel will be created These bins are sensitive to arching AND ratholing It is generally advantageous in the industry to design a mass flow bin, which, when designed properly Calculation method to Design Hoppers and Silos How to Design Efficient and Reliable Feeders for Bulk Solids by John W Carson, PhD and Greg Petro, PE A feeder is an extremely important element in a bulk material handling system, since it is the means by which the rate of solids flow from a bin or hopper is controlled When a feeder stops, solids flow should cease When aHow to Design Efficient and Reliable Feeders for Bulk Solids

INSTALLATION AND SYSTEM GUIDELINES

SYSTEM DESIGN 14 Bulk Material Weighing Systems F Figure 110 illustrates a loss in weight system This is used where a process needs a batch of material (not more than the capacity of the weigh hopper), but that material needs to be fed to the process at a controlled rate The process starts by filling the hopper with at least enoughDesign of Mineral Sand Surge Bin to deliver consistent Lyons J, Hill G, Vadeikis C, Wiche S Innovative Surge Bin Design for Mineral Sands Processing Plant, Recent Advances in Mineral Processing Plant Design Tucson 2009 Historically, mineral sand surge bins were designed without considering the mode of flow within the binMineral Processing Surge Bin DesignSurge Bin Design Large capacity surge bin mining nldcindiain surge bin in coal mine design More About surge bin designs mining Please The system Hyder worked on consisted of a 500 tonne capacity surge bin surge bin designs mining coal russian viewchannelmx surge bin design May 18 2013 A key component was Mineral Technologies innovative surgeSurge Bin In Coal Mine Design espacekuglerch

Feed Mill Design SA Trade Hub

Design capacity = 75 MTPH Assume 4 metric ton capacity mixer Batches per hour = 75/4 = 1875 Cycle time = 60/1875 = 32 minutes Cycle time = 32 x 60 = 192 seconds Surge Bin Liquid Manifold Twin Rotor Mixer Mixer Intervent Surge Bin Pelleting System Pelleting System Capacity is dependent on driveLevel measurement and point level detection in the coal surge bin Process data Measuring task: Level measurement and point level detection Efficient use of the entire container capacity User friendly Simple mounting and setup Very long service life and low maintenance due to robust design ; Reliable switching point ensured through Coal surge bin – level measurement, point level Nominal air capacity: 172 cubic feet 6020 lb, 201 cubic feet 7035 lb, 228 cubic feet 7980 lb, 257 cubic feet 8995 lb, 286 cubic feet 10010 lb Est Usable Capacity: 138 cubic feet 4830 lb, 161 cubic feet 5328 lb, 182 cubic feet 6384 lb, 206 cubic feet 7196 lb, 229 cubic feet 8008 lb HeightIMS Tri Mechanical – Surge Bin 72″ x 72″ – IMS Tri

DESIGN RECOMMENDATION FOR STORAGE TANKS AND

carrying capacity in the structure Design spectra for sloshing, spectra for long period range in other words, damping ratios for the sloshing phenomena and pressures by the sloshing on the tank roof have been presented For aboveground vertical cylindrical storage tanks without any restraining element, such as Funnel Flow bin : the discharge of the product at the center of the bin will be promoted, a funnel will be created These bins are sensitive to arching AND ratholing It is generally advantageous in the industry to design a mass flow bin, which, when designed properly Calculation method to Design Hoppers and Silos Mass flow portable container, Ybranch, and mass flow surge hoppers for dualsided press compacting potent pharmaceutical powder into tablets What’s Next After completion of the functional design for a silo, bin, or hopper, Jenike Johanson can perform accurate load analyses and structural engineering to develop design drawings needed to Silos, Bins, Hoppers Jenike Johanson

PROCESS VESSELS ScienceDirect

The choice of bin design—conical or pyramidal—affects in part the problems noted above Steve (2000) discusses the capacity of a bin as a function of bin geometry and gave equations for the design of bins In nonconical hoppers (eg, a wedgeshaped bin with an elongated outlet), a wider range of conditions for a material can occur without SYSTEM DESIGN 14 Bulk Material Weighing Systems F Figure 110 illustrates a loss in weight system This is used where a process needs a batch of material (not more than the capacity of the weigh hopper), but that material needs to be fed to the process at a controlled rate The process starts by filling the hopper with at least enoughINSTALLATION AND SYSTEM GUIDELINESDesign of Mineral Sand Surge Bin to deliver consistent Lyons J, Hill G, Vadeikis C, Wiche S Innovative Surge Bin Design for Mineral Sands Processing Plant, Recent Advances in Mineral Processing Plant Design Tucson 2009 Historically, mineral sand surge bins were designed without considering the mode of flow within the binMineral Processing Surge Bin Design

Coal surge bin – level measurement, point level

Level measurement and point level detection in the coal surge bin Process data Measuring task: Level measurement and point level detection Efficient use of the entire container capacity User friendly Simple mounting and setup Very long service life and low maintenance due to robust design ; Reliable switching point ensured through Nominal air capacity: 172 cubic feet 6020 lb, 201 cubic feet 7035 lb, 228 cubic feet 7980 lb, 257 cubic feet 8995 lb, 286 cubic feet 10010 lb Est Usable Capacity: 138 cubic feet 4830 lb, 161 cubic feet 5328 lb, 182 cubic feet 6384 lb, 206 cubic feet 7196 lb, 229 cubic feet 8008 lb HeightIMS Tri Mechanical – Surge Bin 72″ x 72″ – IMS Tri 2 天前 Operator adjusts lowers cyclone decelerator arm to top of bin Wand is placed into raw material storage container (drum or Gaylord) Operator adjusts timer dial to desired setting Operator then presses start button Pneumatic conveyor transfers resin into bin until timer times out or Portable Surge Bins, Resin Bin, Bulk Container,

IMS Tri Mechanical Surge Bin 48" x 48" IMS Tri

34 variations of the IMS Tri Mechanical Surge Bin are available Different sizes, capacities, discharge openings, slopes Please carefully check the technical specifications below prior to orderingMass flow portable container, Ybranch, and mass flow surge hoppers for dualsided press compacting potent pharmaceutical powder into tablets What’s Next After completion of the functional design for a silo, bin, or hopper, Jenike Johanson can perform accurate load analyses and structural engineering to develop design drawings needed to Silos, Bins, Hoppers Jenike Johanson The choice of bin design—conical or pyramidal—affects in part the problems noted above Steve (2000) discusses the capacity of a bin as a function of bin geometry and gave equations for the design of bins In nonconical hoppers (eg, a wedgeshaped bin with an elongated outlet), a wider range of conditions for a material can occur without PROCESS VESSELS ScienceDirect

Hoppers, Bins, Tanks, Vessels, and Silos US SYSTEMS

Funnel Flow vs Mass Flow Two important concepts in bin design is Funnel Flow and Mass Flow Funnel Flow In funnel flow, material flows downward by gravity in the middle of the bin with stagnant material remaining along the wall of the vessel Funnel flow can be advantageous when headroom is at a premium and the application is not depending on FIFO (FirstInFirstOut) sequence or uniform flow2 天前 Tank Capacity Calculators Dry Bulk Tank Capacity Calculator for figuring the tank size and tank volume of dry bulk storage tanks including: skirted tanks with door access, drive through skirted silo, elevated tanks with leg support and elevated tanks with structure support; Liquid Flat Bottom Capacity Calculator for figuring the tank size and tank volume of Liquid Flat Bottom TanksDry Bulk Storage Capacity Calculator Since the NEMA design squirrel cage motor operates with full torque at all times, it can “stop and resume” feed at any capacity, even 5000 TPH The control responds accurately and smoothly to any manual, pneumatic, hydraulic or electronic input signalload cell, belt scale, computer – Vibrating Feeder Design Stockpile Reclaim