عنا

مرحبا هل يمكنني مساعدتك؟

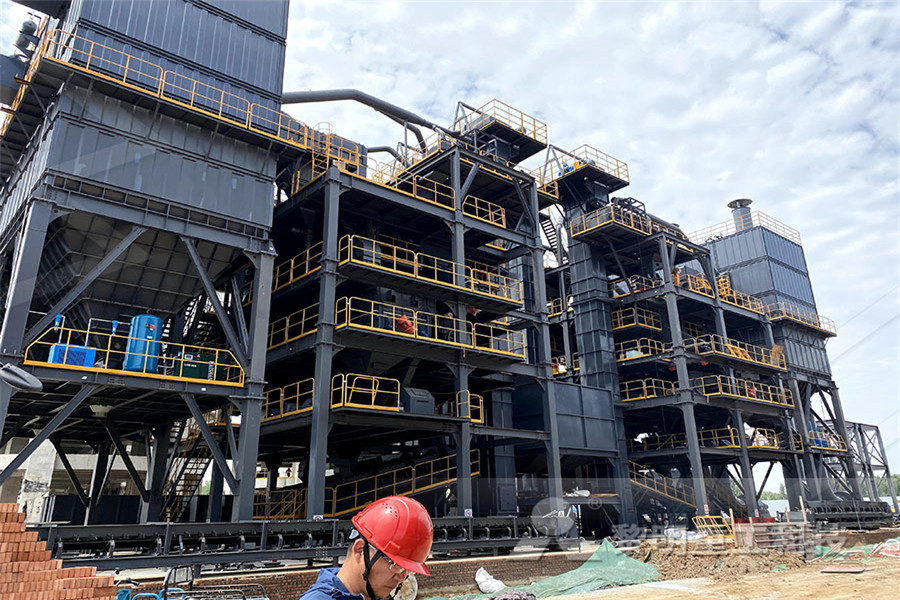

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

manufacturing process of steel balls for mining

2020-10-11T15:10:54+00:00

Manufacturing process of grinding media balls

Transversal rolling of balls from the round billet is economical It differs from other methods due to the possibility to produce grinding balls on the uninterrupted automated aggregates, which allows 2 to 8 times to increase the output and 1015% to reduce the consumption of metal The process involves the following stages:Home; Grinding balls for mining suitable for all mill applications Grinding balls for mining are made from various metals such as steel, hard metal and ceramicHowever, they are commonly manufactured from steel and steel alloys which have superior resistance to abrasion and low wear ratesHardness might be between 15 and 66 on the Rockwell Scale or between 85 to 105 on the Vickers hardness Stainless steel grinding balls for mining / ball millManufacturing process of grinding media balls The process involves the following stages: 1 Incoming inspection of preform For the production of grinding balls, Energosteel uses hot rolled round bar from medium and high carbon and lowalloyed steel produced by the world’s leading metallurgical companiesgrinding media balls manufacturing process ME

manufacturing process of cast iron grinding balls

The Manufacturing process for balls, stainless steel balls precision Abbott manufactures over five billion balls each year in a range of sizes and materials by the forming dies, is removed as balls roll between heavy, cast iron plates Most are of stainless or carbon steel, while the rest are from brass, aluminum, chrome steel, precious metals, and offers glass and plastic Abbott has a special department devoted to the manufacture of precious metal balls, including gold, silver, platinum, palladium, titanium and specialized alloys, for uses such as electrical contacts The Manufacturing process for balls, stainless steel The production process of casting grinding balls: The casting grinding ball is a kind of grinding balls which uses the medium frequency electric furnace to melt the scrap steel, scrap iron and so on The furnace charge is fully melted and the precious Introduction of manufacturing process of casting

Grinding Ball Grinding Steel Ball, Grinding Media Ball

Grinding Ball, ALLSTAR Grindingball, a certified ISO 9001 company, is the worldleading manufacturer of grinding media ball, grinding steel ball, forged steel ball, casting steel ball with annual production capacity of 100,000 metric tonsThe iron and steel manufacturing process begins with mining raw materials, which must then be carefully processed to ensure quality finished products that meet specificationsThere are more than 3,500 different grades of steel with many different Raw Material Mining and Quality Control for Steel Forged steel balls are widely used many areas, such as largescale mines, gold mine, copper ores, alumina ores, iron ores, metal ores, metallurgical mines, cement building materials, power plant, etc There are three types for forged grinding balls They are C grinding ball, Mn grinding ball and special alloy grinding ballsGrinding balls,chrome steel balls,grinding media ball

Steel Balls for Grinding • Sidenor

Steel balls for grinding are produced in a range of 60100mm diameter They are used in ore grinding mills, such as SAG (Semi Autogenous Grinding) mills when it is for initial grinding or ball mills for regrinding The most common applications of these steel balls are in gold, copper, iron, zinc, nickel and silver mining2 天前 Grinding Balls in alloy steel rolled and/or stamped We supply balls on a wide and complete range of hardnesses, with different hardness profiles, to maximize the grinding performance in wear rate and impact endurance, at a regular wear and with tailor Supplier mining grinding media mill steel forged balls The three principal factors in the manufacturing of steel grinding balls used in mining industry are the material, the forging process and the heat treatment If this parts fail during drop ball Steel Grinding Balls Failures in Drop Ball Test (DBT)?

Steel Balls for Ball Seat Valves Balls for Oil Industry

The 52100 Chrome balls have an HRc of 6067 hardness while the S2 Rockbit balls have an HRc of 5559 The S2 Rockbit balls are also used in the rotary bits for the mining industry We also offer ceramic balls used in the oil and gas sector, often used in chemical injection pumps and valve applications for the supreme wearability of the materialMining operations require grinding media or grinding balls for crushing minerals or rock extracts in order to seperate them and obtain pure powders Crushing is done by contact between the grinding balls and the minerals which are placed together inside big mixing containers : the grinding balls crush the raw ore thanks to their weight and Grinding media / Grinding balls CIMAPThe feed can be dry or wet, as for dry materials process, the shell dustproof to minimize the dust pollution Gear drive mill barrel tumbles iron or steel balls with the ore at a speed Usually, the balls filling rate about 40%, the mill balls size are initially 30–80 cm Ball Mills Industry Grinder for Mineral Processing

CITIC HIC Response to AntiDumping

The manufacturing process of hotrolled steel balls controls all aspects of production, including steel bar billets and heat treatment The process is computer controlled which maintains quality, enhances production efficiency, and reduces human and environmental factors on productivity Introduction to CITIC Heavy Industries DK Machine offers valve ball and seat manufacturing and repair, and provides spherical grinding services for many industries including military, mining, pulp and paper, petroleum and chemical We produce precision valve balls for use in severe duty, high pressure, and high tolerance applicationsDK Machine Valve Balls, Seats, Spherical Grinding, Steel shot for sale Leading Steel shot manufacturer in India We are the supplier exporter of 410 steel shot, stainless steel shot, 28 ga steel shot, 20 ga steel shot, and 16 ga steel shot Buy steel shot at affordable price in IndiaSteel Shot for Sale Steel Shot Manufacturer

SAG Molycop

The Molycop range of SAG grinding balls is prepared for impact Through an innovative manufacturing process we’ve produced a ball with greater impact resistance and reduced spalling compared to the standard SAG ball, ready to perform in the highest impact SAG milling environmentsForged steel balls are widely used many areas, such as largescale mines, gold mine, copper ores, alumina ores, iron ores, metal ores, metallurgical mines, cement building materials, power plant, etc There are three types for forged grinding balls They are C grinding ball, Mn grinding ball and special alloy grinding ballsGrinding balls,chrome steel balls,grinding media ball 2 天前 Grinding Balls in alloy steel rolled and/or stamped We supply balls on a wide and complete range of hardnesses, with different hardness profiles, to maximize the grinding performance in wear rate and impact endurance, at a regular wear and with tailor Supplier mining grinding media mill steel forged balls

Grinding media / Grinding balls CIMAP

Mining operations require grinding media or grinding balls for crushing minerals or rock extracts in order to seperate them and obtain pure powders Crushing is done by contact between the grinding balls and the minerals which are placed together inside big mixing containers : the grinding balls crush the raw ore thanks to their weight and 825 Manufacturing Process 83 Downstream of Forged Steel Grinding Balls 831 Leading Distributors/Dealers of Forged Steel Grinding Balls Figure Global Forged Steel Grinding Balls for Mining Industry Sales and Growth Rate (20132018) Figure Example of Thermal Power PlantForged Steel Grinding Balls Market Trends, Size The feed can be dry or wet, as for dry materials process, the shell dustproof to minimize the dust pollution Gear drive mill barrel tumbles iron or steel balls with the ore at a speed Usually, the balls filling rate about 40%, the mill balls size are initially 30–80 cm Ball Mills Industry Grinder for Mineral Processing

CITIC HIC Response to AntiDumping

The manufacturing process of hotrolled steel balls controls all aspects of production, including steel bar billets and heat treatment The process is computer controlled which maintains quality, enhances production efficiency, and reduces human and environmental factors on productivity Introduction to CITIC Heavy Industries DK Machine offers valve ball and seat manufacturing and repair, and provides spherical grinding services for many industries including military, mining, pulp and paper, petroleum and chemical We produce precision valve balls for use in severe duty, high pressure, and high tolerance applicationsDK Machine Valve Balls, Seats, Spherical Grinding, The clinker is then cooled and ground to a fine powder in a tube or ball mill A ball mill is a rotating drum filled with steel balls of different sizes (depending on the desired fineness of the cement) that crush and grind the clinker Gypsum is added during the grinding process to provide means for controlling the setting of the cementCement: Materials and manufacturing process

Densification Behavior of 316L Stainless Steel Parts

This manufacturing process is characterized by highly localized laser energy inputs during short interaction times which significantly affect the densification process In this present work, experimental investigation of fabricating 316L stainless steel parts by SLM process was conducted to determine the effect of different laser energy The Manufacturing Process The process of extracting copper from copper ore varies according to the type of ore and the desired purity of the final product Each process consists of several steps in which unwanted materials are physically or chemically removed, and the concentration of copper is progressively increasedHow copper is made material, used, processing,