عنا

مرحبا هل يمكنني مساعدتك؟

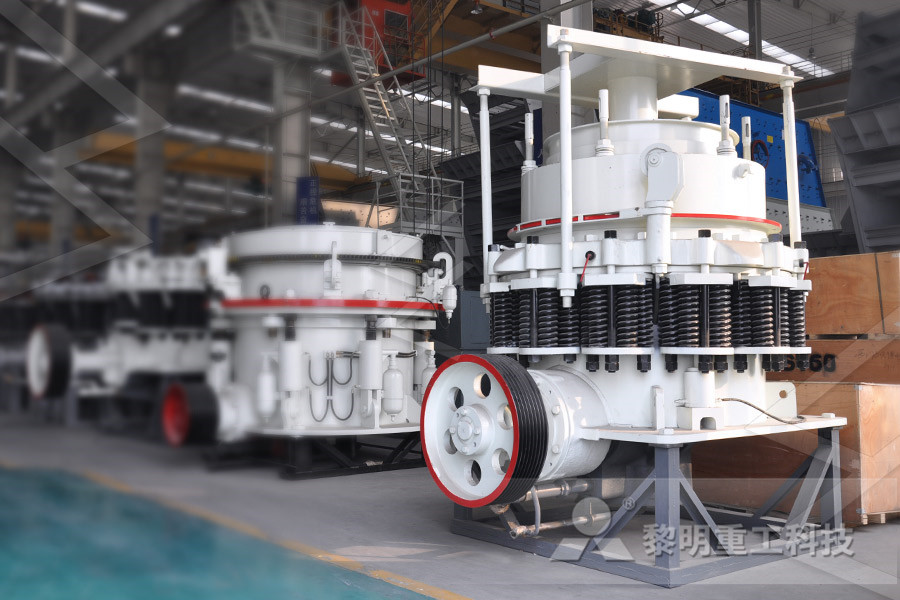

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

ball mill pdf size for gold

2023-10-12T13:10:56+00:00

ball mill pdf size for gold mikadobestpl

Ball mill pdf size for gold 25” are sent to the grinding section for further size reductionThe screen deck oversize, consisting of particles over 025”, is recycled Download PDF MDPI 16 Nov 2020 This problem can be partially solved by scalingup the geometric size of ball mills What is ball milling? A ball mill is a type of grinder used to grind materials into extremely fine powder 7 Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speed 8 Types of Ball MillsBall Milling University of Massachusetts Boston In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner wear and Calculate and Select Ball Mill Ball Size for Optimum

Grinding in Ball Mills: Modeling and Process Control

The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material (feeders), and the system for discharging the output product The size of a mill is usually characterized by the ratio “length to diameter” and this where d bmax is the maximum size of feed (mm); σ is compression strength (MPa); E is modulus of elasticity (MPa); ρb is density of material of balls (kg/m 3); D is inner diameter of the mill body (m) Generally, a maximum allowed ball size is situated in the range from D /18 to D/24 The degree of filling the mill with balls also influences productivity of the mill and milling efficiencyBall Mill an overview ScienceDirect Topics involve grinding) With Lloyd's ball milling book having sold over 2000 copies, there are probably over 1000 home built ball mills operating in just America alone This article borrows from Lloyd's research, which was obtained from the commercial ball milling industry, and explains some of the key design criteria for making your own ball millPage 1 Ball Milling Theory

Ball Mills Mineral Processing Metallurgy

Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill Ball Size as Initial Charge Commercial ball sizes 10 – 150 mm; Number, size and mass of each ball size depends on mill load and whether or not the media is being added as the initial charge For the initial chargin of a mill, Coghill and DeVaney (1937) defined the ball size as a function of the top size of the feed, ie, d↓V = 040 AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill We discuss the types of ball mill, the basic principles of the ball mill, how it works, the details of design including equations for optimum dimensions in all cases, some manufacturers for the ball mill, and estimation of the cost the ball mill 6 1 Introduction Ball mill is an efficient tool for grinding many materials into fine powderBall Mill SlideShare

Optimum choice of the makeup ball sizes for

For a single size of makeup ball, the mass fractions in the mill within the size ranges are calculated from: (11) m k = d k u 4 − Δ − d k l 4 − Δ d max 4 − Δ − d min 4 − Δ where d k u and d k l represent the upper and lower boundaries of the ball size interval k, d max is the largest ball size in the mill, and d min is the Autogenous mills, semiautogenous mills and ball mills for wet SAG and ball mill for gold ore grinding One of three SAG mills with 975 m diameter and 2 x 4000 kW drive power These mills the mill lining and free design »More detailedball mill design pdf for gold MiningBall Mill Specification Pdf Ball Mill Kgs Price India Cam Ball Mill Commercial Gold Ball Mill For Flotation Cell Ceramic Ball Mill For Sale In The Usa Worldcrushers Ball Mill Aggregate Plant Products Co In California Mining C Bingham Canyon Mine In Pit Ball Mill Ball Mill Mesh Screen SizeBall Mill neuroingelheimde

Ball Mill, Rod Mill, Raymond Mill, HGM Superfine

Feeding size: ≤25≤30mm Output size: 0173mm0044mm (80325mesh) Fumine's ball mill is of energy conservation and environment protection and efficiency of grinding It is in stable work performance Fumine truly puts the interests of users into mind indonesia ball mill maintenance pdf 2017; nigeria grinding media design for cement A gold mine was surveyed to investigate the ball milling requirements of an industrial HPGR circuit Two surveys of the ball mill operating at different conditions found that milling efficiency (PDF) The effect of roller press grinding on ball milling This paper covers theoretical and experimental explorations for the sake of determining the optimal ball charge in mills In the first part of the paper, on the basis of the theoretical analysis of the energygeometric correlations, which are being established during the grain comminution by ball impact, as well as on the basis of the experiment carried out on grinding quartz and copper ore in [PDF] The optimal ball diameter in a mill Semantic

(PDF) DESIGN AND FABRICATION OF MINI BALL MILL

PDF This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder The effect of ball size on mill performance 1 Calculation of ball mill capacity The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting There are many factors affecting the production capacity of the ball mill, in addition to the nature of the material (grain size, hardness, density, temperature and humidity), the degree of Ball Mill Parameter Selection Calculation Power fractions The long residence time of the gold within the grinding circuit can cause some of the GRG to become nongravity recoverable due to smearing on to grinding media, mill liners and gangue minerals This effect is minor as more than 98% of the GRG entering the ball mill remains gravity recoverable after grinding (LaPlante, 2000)GRAVITY RECOVERY OF GOLD FROM WITHIN GRINDING

TECHNICAL NOTES 8 GRINDING R P King

the mill is used primarily to lift the load (medium and charge) Additional power is required to keep the mill rotating 813 Power drawn by ball, semiautogenous and autogenous mills A simplified picture of the mill load is shown in Figure 83 Ad this can be used to establish the essential features of a model for mill powerBall Mill Specification Pdf Ball Mill Kgs Price India Cam Ball Mill Commercial Gold Ball Mill For Flotation Cell Ceramic Ball Mill For Sale In The Usa Worldcrushers Ball Mill Aggregate Plant Products Co In California Mining C Bingham Canyon Mine In Pit Ball Mill Ball Mill Mesh Screen SizeBall Mill neuroingelheimdeA gold mine was surveyed to investigate the ball milling requirements of an industrial HPGR circuit Two surveys of the ball mill operating at different conditions found that milling efficiency (PDF) The effect of roller press grinding on ball milling

[PDF] The optimal ball diameter in a mill Semantic

This paper covers theoretical and experimental explorations for the sake of determining the optimal ball charge in mills In the first part of the paper, on the basis of the theoretical analysis of the energygeometric correlations, which are being established during the grain comminution by ball impact, as well as on the basis of the experiment carried out on grinding quartz and copper ore in 1 Calculation of ball mill capacity The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting There are many factors affecting the production capacity of the ball mill, in addition to the nature of the material (grain size, hardness, density, temperature and humidity), the degree of Ball Mill Parameter Selection Calculation Power Mill Chute Area CalculationThe following criteria must be considered while sizing the ball mill inlet chute: The dimensions/areas for a chute should as far as possible be chosen according to the outlet flange for a machine The smallest side length in a chute must be min 5 times the max lump size Min chute size for lumpy material: 250mm x (PDF) DESIGN AND ANALYSIS OF BALL MILL INLET

Ball Mill, Rod Mill, Raymond Mill, HGM Superfine

Feeding size: ≤25≤30mm Output size: 0173mm0044mm (80325mesh) Fumine's ball mill is of energy conservation and environment protection and efficiency of grinding It is in stable work performance Fumine truly puts the interests of users into mind indonesia ball mill maintenance pdf 2017; nigeria grinding media design for cement Lopulco Mill Plasster Plant lopulco mill design drawings Jaw Crusher One of the cement ball mill jaw crusher for since the new design install ball mill design drawing ball mill design drawing gross power calculator SMC Testing power at pinion would be about 67 lower than the gross power draw sawmill plans eBay Ballmill Design DrawingBall mill crusher drawings beckersmuehlede Ss – Ball size factor To determine the power that a dry grinding needs, full grate discharge mill Equation 1 is multiplied by the factor of 108 A multicompartment ball mill consists of two or more grate discharge ball mills in series The same equation is used to calculate the power that each ball mill compartment should draw The total CALCULATION OF THE POWER DRAW OF DRY

The operating principle of the ball mill Primo Pizza

The operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls Then, discharge of ground material performed the mill is used primarily to lift the load (medium and charge) Additional power is required to keep the mill rotating 813 Power drawn by ball, semiautogenous and autogenous mills A simplified picture of the mill load is shown in Figure 83 Ad this can be used to establish the essential features of a model for mill powerTECHNICAL NOTES 8 GRINDING R P King