عنا

مرحبا هل يمكنني مساعدتك؟

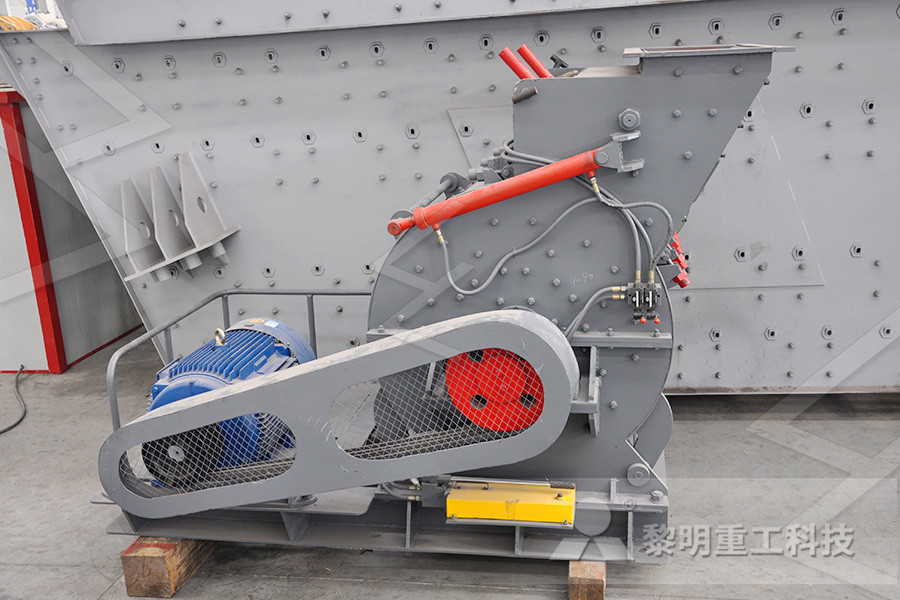

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

vertical roller mills maintenance

2022-06-03T17:06:07+00:00

Vertical Roller Mill Routine Maintenance

Vertical Roller Mill Routine Maintenance To prolong the service life of vertical roller mill, reduce the number of repair, we must do a good job in vertical roller mill routine maintenance, specific steps may refer to the following maintenance method Often listen to vertical roller mill running sound is normal, there is no noiseside of feed near the roller crushing face Avoid excess water spray Bypassing of hot air also creates this problem; 6 Analyse reject closely to identify hard materials; 7Vertical Roller Mill Maintenance LinkedInMaintenance and repair of vertical roller mill is a highly technical and specialized business, which should be performed by experts Vertical roller mill maintenance can be broken down into three general areas; rolls and bearingsVertical Roller Mill Routine Maintenance And Repair

Vertical Roller Mill Maintenance

When the device is used for a period of time, the operation personnel needs a complete overhaul of equipment, especially for dry mill, vertical mill and other equipment of the grinding roller and grinding ring, blade wearing parts, necessary to handle according to the degree of wear, if wearing parts wear to a certain degree need to repair, when the wear degree is more serious that requires the user to change Maximise mill performance with a reliable maintenance strategy The vertical roller mill VRM is firmly established in cement plants all over the world The biggest issues facing plants are not due to the equipment itself but more to do with how well mill maintenance is understood and how the mill is looked after following commissioningVertical Roller Mill Maintenance lianestreblowdeVertical Roller Mills For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product qualityvertical roller mill maintenance huberbeilngriesde

Vertical Roller Mill Ube Maintenance Manual

Milling Equipment: vertical roller mill ube maintenance manual A class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine grinding in the field of industrial grinding The finished product can be controlled freely from 0 Vertical roller mills offer supreme grinding with high energyefficiency Years of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertlydesigned vertical roller mill Vertical Roller Mills Welding Alloys’ Solution A unique knowledge of vertical roller mill (VRM) grinding components and repair requirements Welding Alloys designed cored wires with wear characteristics specially adapted for these applications in mill repairs We can supply new advanced grinding components using our wires and welding techniquesVertical Roller Mill (VRM) Repair Welding Alloys

MVR vertical roller mill with planetary Gebr Pfeiffer

Wear protection/maintenance Depending on the abrasiveness of the material to be ground and areas to be protected, different wear materials are used on our vertical roller millsVertical Roller Mill Maintenance Contact with dry grinding equipment friends all know, the equipment is not only large volume is expensive, but also the need of the user during use user maintenance, otherwise it will be “emotional” effect of productionVertical Roller Mill MaintenanceVertical Roller Mill Maintenance and Repair Vertical roller mills became increasingly dominant for grinding raw materials mainly for the cement industry due to their high energy efficiency and excellent drying capacity Maintenance and repair of vertical roller mill is a highly technical and specialized business, which should be performedvertical roller mill maintenance pdf huberbeilngriesde

Maintenance of Cement plant vertical roller mill wear

Maintenance of Cement plant vertical roller mill wear parts News Date: 13:30:38 The cement vertical roller mill design allows the option of rotating the roller segments 180 degrees before replacing They can also be hardfaced in place with a standard rewelding procedure VRM onsite weld repair, maintenance and rebuilding services, cement plant vertical mill in situ hardfacing of rollers and grinding tables to increase service life A unique knowledge of vertical roller mill (VRM) grinding components and repair requirements Smart welding concept for vertical roller mills Consistency and Customer ServiceVertical Roller Mill (VRM) Repair Welding Alloys Vertical roller mills (VRMs) have become the equipment of choice for raw and solid fuel grinding in cement factories Increasingly modern cement plants also use VRMs for cement grinding However, opportunities for the optimisation of VRMs are less obvious than with ball mills as all processes of grinding, drying, classification and regrinding Vertical roller mill optimisation

Atlas Vertical Roller Mill NETZSCH Grinding

NETZSCH Ecutec's Atlas Vertical Roller Mills has been developed for more efficient fine grinding of soft to mediumhard materials The Atlas is a roller airswept mill designed for continuous operation with minimum maintenance The fundamental difference between the Atlas and other tableroller mills is the bearing arrangement for the grinding table, which is incorporated into the base of the The vertical roller mills produced by our company have been applied intensive in China’s market and abroad feature multifunction of material drying, grinding, selecting conveying as a whole, have a series of advantages of high yield production, less occupied place, lower power consumption, easy maintenance, high operation rate and life Vertical Roller Mill北方重工 NHI Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newlybuilt] and about 230 million US$ [retrofitted], including the Vertical roller mill for raw Application p rocess materials

» Vertical power Evolution

In addition, vertical roller mills occupy less floor space than ball mills The quality of the cement produced by both machines is almost the same, although vertical roller mills have a less complicated structure and higher efficiency, and require less maintenance “China’s cement industry has a common goal, namely to eliminate ball mills – Lower maintenance costs • Maintained production rates • Lower power consumption • Reduced operating costs • Lower Total Cost of Ownership New WearResistant Welding Technology for Vertical Roller Mills Nick Sutherland Welding Alloys Group s New WearResistant Welding Technology for Vertical Vertical Roller Mill Maintenance Contact with dry grinding equipment friends all know, the equipment is not only large volume is expensive, but also the need of the user during use user maintenance, otherwise it will be “emotional” effect of productionVertical Roller Mill Maintenance

vertical roller mill maintenance pdf huberbeilngriesde

Vertical Roller Mill Maintenance and Repair Vertical roller mills became increasingly dominant for grinding raw materials mainly for the cement industry due to their high energy efficiency and excellent drying capacity Maintenance and repair of vertical roller mill is a highly technical and specialized business, which should be performed Structure and maintenance of Pfeiffer's MPS vertical roller mill The structure of the MPS BC series, to which all mills producing cement or BFS powder belong, basically corresponds to that of the MPS vertical roller mills that have been used for cement MPS vertical roller mills for slag and slag cements The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etcOperation Guide for Vertical Roller Mill in Cement

Vertical Roller Mill北方重工 NHI

The vertical roller mills produced by our company have been applied intensive in China’s market and abroad feature multifunction of material drying, grinding, selecting conveying as a whole, have a series of advantages of high yield production, less occupied place, lower power consumption, easy maintenance, high operation rate and life Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newlybuilt] and about 230 million US$ [retrofitted], including the Vertical roller mill for raw Application p rocess materials Vertical roller mills (VRMs) have become the equipment of choice for raw and solid fuel grinding in cement factories Increasingly modern cement plants also use VRMs for cement grinding However, opportunities for the optimisation of VRMs are less obvious than with ball mills as all processes of grinding, drying, classification and regrinding Vertical roller mill optimisation

Vertical Roller Mill for Clinker Grinding

Vertical Roller Mill for Clinker Grinding 1 First Principles of Grinding Ball mills and vertical mills use different forces to achieve the necessary size reduction of clinker and gypsum plus other materials – such as pozzolan, flyash, limestone and slag – that may also be part of the feed to the millVertical Roller Mills The roller grinding mill technology, patented in 1928 and continuously developed since then has become synonymous with Loesche’s pioneering engineering and knowhow The material to be ground is crushed between the rotating grinding Vertical Roller Mills Ammermann Pty LtdUltrafine vertical roller mill has high reliability, good stability, directly reduces the maintenance, repair, and thus directly reduces the cost of repair material expenditure The normal production situation, vertical mill repair material cost is the most direct roll grinding, grinding and LUM Ultrafine Vertical Roller Mill Gravel Mill