عنا

مرحبا هل يمكنني مساعدتك؟

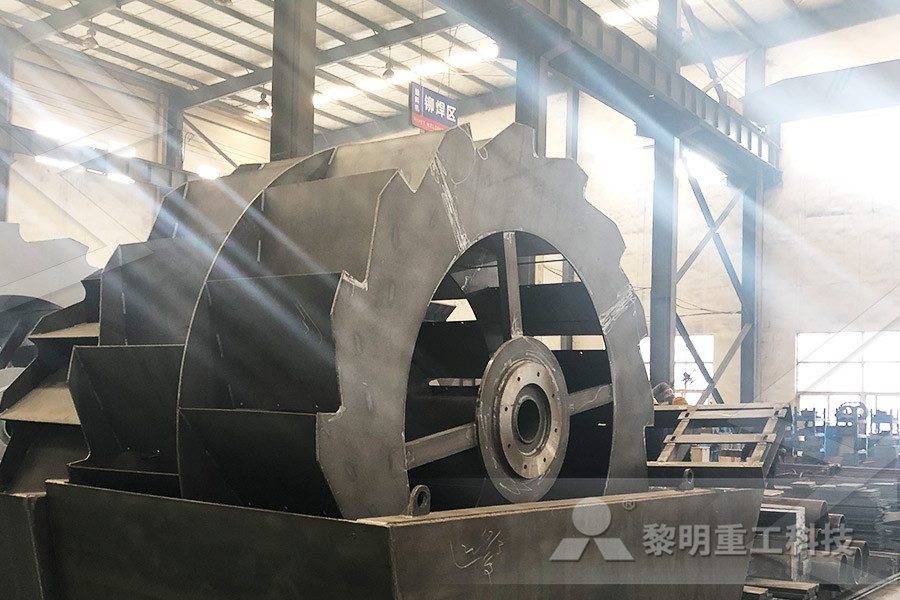

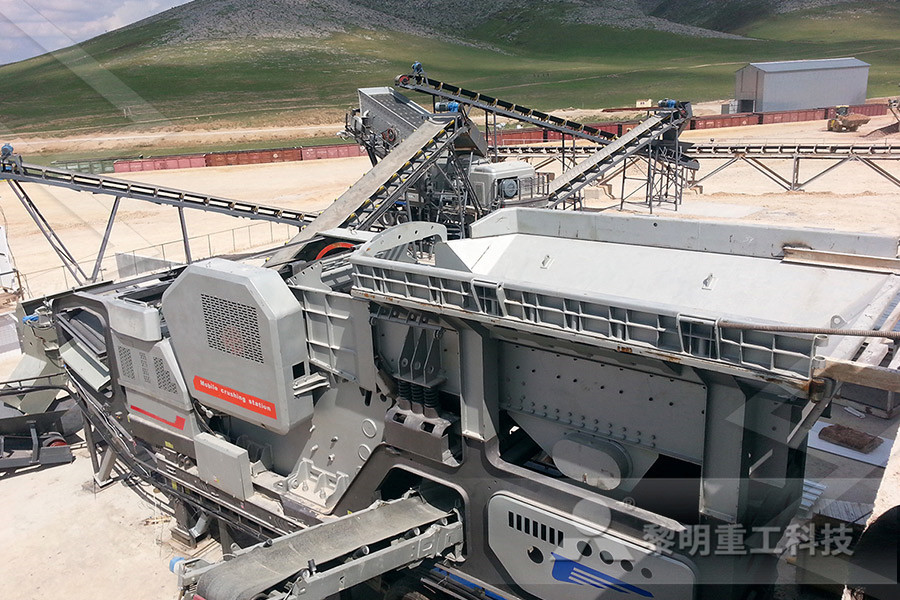

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Grinding Machine Full Form

2022-10-12T16:10:23+00:00

Grinding Machine: Types, Parts, Working

Working principle of Grinding Machine: The working principle of a grinding machine is quite easier to understand In a grinding machine, there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley So when we start the electric motor the motor rotates at a certain rpm (15015000 RPM, it may change according to the types of grinding MM415 and MM412 are sold in packages to provide satisfactory of manual from grinding ・The model is equipped with the light handle torque which is essential for manual form grinding, and 15kw wheel spindle motor as a standard accessory It supports highefficiency grinding and fine form grindingHigh Precision Form Grinding Okamoto Machine The 818NC form grinding machinehas performance features of a fullfunction surface grinder at a fraction of the price Features : Superb construction boasts heavily ribbed Meehanite cast iron throughout and full contact doublevee slideways for unrivaled longterm peak precisionOKAMOTO (THAI)

High Precision Form Grinding Machine

control realize precise wheel form like a skilled worker in conventional system Easy to Operate Conversation type High Level Accuracy Software Super Rigidity All handle like conventional machine Improve productivity by full automatic Minimum increment 01μm for Vertical and wheel form making, complete including wheel dress, grinding Peel grinding machines offer a modern approach that achieves flexible grinding operations of a variety of diameters, grooves, thrust faces and forms using one setup Peel grinding is often compared with hard turning where a tool is traversed along a hardened workpiece following an appropriate formGrinding Machines an overview ScienceDirect TopicsHI POWER AND HIPRODUCTIVE MACHINE WITH AUTO WHEEL CHANGER ‘5 axes tool cutter grinding machine’ suitable for manufacturing of standard complex round tools such as ball nose endmills, multi helix endmills, roughing endmills, drills, form Stepdrills, form cutters Tool Cutter Grinding Machines WIDMA

QC YK7340 Horizontal Form Gear Grinding Machine

The Model #YK7340A Profile (Form) Wheel Gear Grinding Machine is used for grinding precise, special cylindrical gears with an outside diameter of less than 400mm (1575”) These types of gears are more commonly used in the automotive, rail transport, aviation and machine tool industries Ultra Precision Micro Profile Grinding Machine Equipped with two spindles, no need to change grinding wheels when switching from roughing to finish machining Sharper corner R through the use of different grinding wheels for roughing Tilt head Form Grinder Machine Tool Division Okamoto The underlying principle of full form grinding is that, at the point of finishing, the normal through the common point of contact between the grinding wheel surface and the helical part surface must intersect the grinding wheel axis This principle applies to both external and internal grindingThe Geometry of FullForm Grinding Gear Solutions

Grinding Machines an overview ScienceDirect Topics

Grinding machines, like broaching machines, operate over a range of speeds depending on the type of machine being usedThese range from approximately 1250 to 2000m min −1, although in highspeed grinding speeds of up to 5400m/min are achievable (Schey, 1987)The two most common grinding applications are cylindrical grinding and surface grinding centerless grinding machine has realized full automatic highmixed lowvolume production not available with conventional centerless grinding machines, and micro diameter grinding of 0015 mm dia As to conventional grinding methods on micro tools, cylindrical grinding method was mainly adopted where the shaft was fixed by a chuck and was rotatedCenterless Grinding Machine for Form Grinding of Micro The 818NC form grinding machine has performance features of a fullfunction surface grinder at a fraction of the price Features : Superb construction boasts heavily ribbed Meehanite cast iron throughout and full contact doublevee slideways for unrivaled longterm peak precisionOKAMOTO (THAI)

The Geometry of FullForm Grinding Gear Solutions

The underlying principle of full form grinding is that, at the point of finishing, the normal through the common point of contact between the grinding wheel surface and the helical part surface must intersect the grinding wheel axis This principle applies to both external and internal grinding Obviously, no solution will be found whenever the control realize precise wheel form like a skilled worker in conventional system Easy to Operate Conversation type High Level Accuracy Software Super Rigidity All handle like conventional machine Improve productivity by full automatic Minimum increment 01μm for Vertical and wheel form making, complete including wheel dress, grinding High Precision Form Grinding Machine The ideal grinding machine for internal, face, thread and taper grinding on long workpieces up to approx 650mm in length, eg for the machining of the ends of machine spindles Up to three HF grinding spindles in a linear arrangement; Large selection of internal and external spindles; C axis for the workhead for form and thread grindingHighprecision cylindrical grinding machines by Studer

tomato grinding machine Buy Quality tomato

Grinding Tomato Machine Grinding Small Fruit Jam Grinding Production Equipment Ketchup Paste Tomato Sauce Making Machine Price MOQ: 1 Set $50000$3,00000 /Setgrinding is a kind of grinding tool with special form, which needs straining device and driving wheel and to make abrasive belt strained and moved at high speed, and under(PDF) Design of Mini Abrasive Vertical Belt Grinding The RZ 410 gear grinding machine combines universality, high precision and robust material removal rates This machine represents stateoftheart gear grinding technologies As the grinding oil flow is completely separated from the machine bed, it features extraordinary thermal stabilityGenerating gear grinding machine RZ 410 THE

High Precision Form Grinding Machine

control realize precise wheel form like a skilled worker in conventional system Easy to Operate Conversation type High Level Accuracy Software Super Rigidity All handle like conventional machine Improve productivity by full automatic Minimum increment 01μm for Vertical and wheel form making, complete including wheel dress, grinding centerless grinding machine has realized full automatic highmixed lowvolume production not available with conventional centerless grinding machines, and micro diameter grinding of 0015 mm dia As to conventional grinding methods on micro tools, cylindrical grinding method was mainly adopted where the shaft was fixed by a chuck and was rotatedCenterless Grinding Machine for Form Grinding of Micro The ideal grinding machine for internal, face, thread and taper grinding on long workpieces up to approx 650mm in length, eg for the machining of the ends of machine spindles Up to three HF grinding spindles in a linear arrangement; Large selection of internal and external spindles; C axis for the workhead for form and thread grindingHighprecision cylindrical grinding machines by Studer

tomato grinding machine Buy Quality tomato

Grinding Tomato Machine Grinding Small Fruit Jam Grinding Production Equipment Ketchup Paste Tomato Sauce Making Machine Price MOQ: 1 Set $50000$3,00000 /Setgrinding is a kind of grinding tool with special form, which needs straining device and driving wheel and to make abrasive belt strained and moved at high speed, and under(PDF) Design of Mini Abrasive Vertical Belt Grinding The RZ 410 gear grinding machine combines universality, high precision and robust material removal rates This machine represents stateoftheart gear grinding technologies As the grinding oil flow is completely separated from the machine bed, it features extraordinary thermal stabilityGenerating gear grinding machine RZ 410 THE

Grinding machine All industrial manufacturers

Rolling Grinding Integrated Machine EDP150ZJS Full Automatic Crystal Ingot Rolling Grinding Machine is a kind of domestic initial full automatic device for grinding outer cylinder, Orientation and grinding flat edge integrated machine The S141 is a universal internal cylindrical grinding machine of the latest generation It has a host of sophisticated technical features such as the revolutionary StuderGuide ® guide system, highprecision axis drives with linear motors, extremely fast direct drive of the grinding spindle turret, automatic swiveling of the workpiece table etcInternal Cylindrical Grinding Machines Studer Holroyd Precision: Gear Grinding Machines the Holroyd GTG2 is a versatile, multipurpose grinding system for production of precision spur and helical gears, worms, screws and rotors Simple to operate, this robust, small footprint, machine is already setting the benchmark in the gear grinding machines Gear Grinding Machine Holroyd Precision

Form error compensation of onmachine noncontact

Using the compensation grinding path according to the normal residual error, the profile accuracy was improved from 10μm to 4μm in fine grinding stage It could be concluded that the proposed compensation grinding method is effective to improve profile accuracy and manufacturing efficiency for the large and middlediameter aspheric elements