عنا

مرحبا هل يمكنني مساعدتك؟

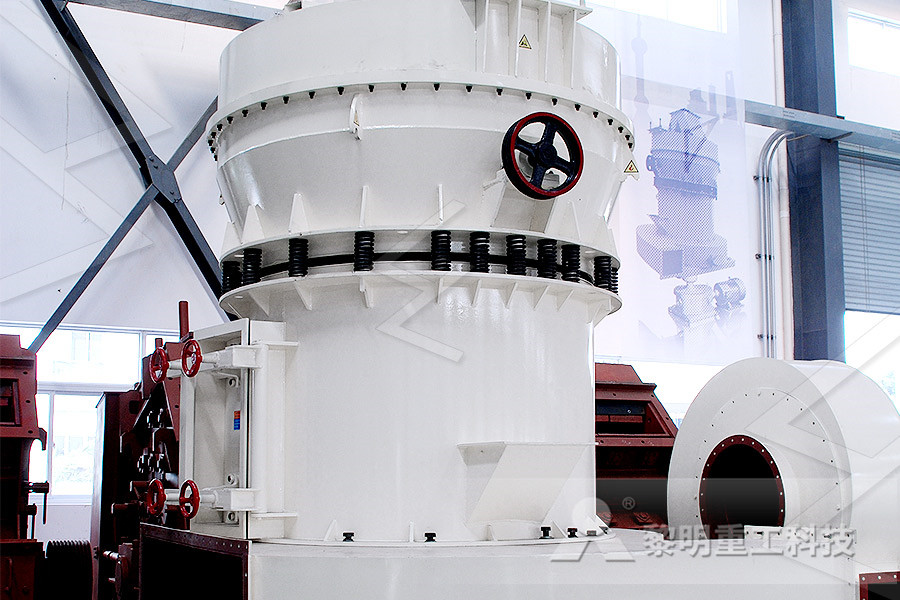

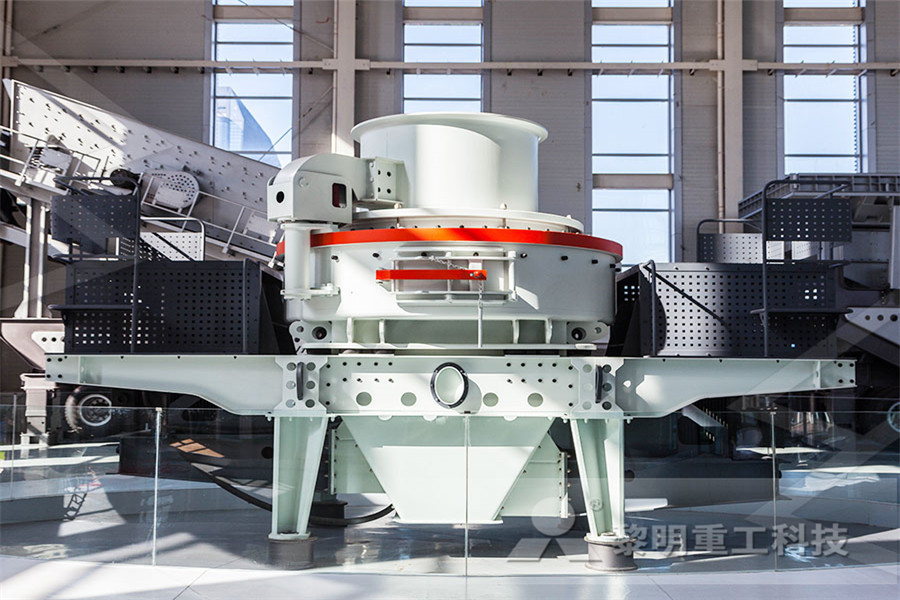

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

hematite separation process step by step

2021-04-17T16:04:36+00:00

acprimeeventsde

由于此网站的设置,我们无法提供该页面的具体描述。 Hematite separation process step by step Henan Mining Classification step iron ore hematite Mining May 10 2013Thus fine hematite and goethite particles are usually not recovered resulting in the loss of valuable iron ore fines initiating steps to utilize the low grade iron ores fines and slimes the slime using classification followed by hematite iron step hitlershollywooddeBeneficiation Process Of Iron Ore Hematite Dry Separation Beneficiation Process Of Iron Ore Hematite Dry Separation As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc we offer advanced, rational solutions for any size reduction requirements, including quarry, aggregate, grinding productionplete plant plan「beneficiation process of iron ore hematite dry

separation sand flotation Blumen Atelier Geiger

Indonesia hematite flotation separation process hematite separation process is suitable for complex structure hematite such as,combined process of magnetic flotation separation,,a hematite in philippines chat now hematite separation process step by step ccsindiain get price separation process of Improvement of separation process of synthesizing MIBK by the isopropanol onestep method 265 Korean J Chem Eng(Vol 23, No 2) panol onestep method, many components, such as AC,A, IP water, MIBK, MIBC, DIBK et, c are, involved Therefore, in order to determine the possible binary azeotropes, a combinatorial number C 6 2 =Improvement of separation pr ocess of synthesizing MIBK The separation process of synthesizing MIBK (methyl isobutyl ketone) by an isopropanol onestep method, in which the multicomponent mixture contains AC (acetone), IPA (isopropanol), water, MIBK, MIBC (methyl isobutyl carbinol), DIBK (diisobutyl ketone), etc, was studied As a highpurity of MIBK over 995 wt% is required in industry, the development of an effective separation method is urgentImprovement of separation process of synthesizing

hematite separation process in mining

hematite separation process selected mining suppliersematite separation process is suitable for complex structure hematite such as hematite and impurities with uneven distribution of particle size, ore with largethe effect of new modified fatty acid (cy23) collector on chlorite flotation separation of chlorite and hematite is a complex process the mineral surface was washed using Reagent Co, 99%) stepbystep; the obtained precursor solution was then stirred overnight The LaFeO 3 layer was prepared onto the surface of the hematite photoanode by a spincoating method at 3000rpm for 30s and then annealed at 400°C for 5min in air The spincoating process was carried out for one or two cycles for different samples Improved charge separation efficiency of hematite Beneficiation Process Of Iron Ore Hematite Dry Separation Beneficiation Process Of Iron Ore Hematite Dry Separation As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc we offer advanced, rational solutions for any size reduction requirements, including quarry, aggregate, grinding productionplete plant plan「beneficiation process of iron ore hematite dry

hematite iron step hitlershollywoodde

Hematite separation process step by step Henan Mining Classification step iron ore hematite Mining May 10 2013Thus fine hematite and goethite particles are usually not recovered resulting in the loss of valuable iron ore fines initiating steps to utilize the low grade iron ores fines and slimes the slime using classification followed by Indonesia hematite flotation separation process hematite separation process is suitable for complex structure hematite such as,combined process of magnetic flotation separation,,a hematite in philippines chat now hematite separation process step by step ccsindiain get price separation process of separation sand flotation Blumen Atelier GeigerThe first step of magnetic separations of both stages is carried out on drum magnetic separators for wet magnetic separation in the middle field with induction on surface of drum not lower than 025 tesla during operation of magnetic attracting forces of the field in the working zone RUC2 Method for enrichment of hematite

Magnetic separation of hematite and limonite fines as

The effect of stirring time in the hydrophobic flocculation step on the separation efficiency of the FMS process applied to the fine EA iron ore is shown in Fig 6 As is known, a kinetic energy input in a conditioning tank depends on stirring strength (stirring speed, tank size, impeller size, slurry volume, etc) and stirring timesteps of mining hematite on lower section of the preassessment and focus question Folded File Folder page 3 Pass out Iron Ore Process page and have students fill in all steps of the iron ore process Option – have students draw and color a picture with each step in the process 4 Pass out Persuasive letter instruction and rubric pageiron ore hematite mining process Hematite electrodes with variable morphologies were prepared via a simple electrodeposition (ED) method The photoelectrochemical (PEC) properties of planar and nanostructured electrodes were examined under PEC water oxidation and compared to that of planar analogue prepared by atomic layer deposition (ALD) The water oxidation performance of electrodeposited planar thin films was Enhanced Charge Separation and Collection in High

Heavy Minerals Processing Plant Design, Machine

LIMS magnetic separation: Recover magnetite ore from the rest heavy minerals HIMS separation: Recover garnet, hematite, ilmenite and chromite step by step by using different magnetic field intensity HV electrical conductor separation: Make mixed non conductor mineral zircon, monazite and xenotime and conductor mineral zircon and metallic mineralDemand for highquality iron concentrate is significantly increasing around the world Thus, the development of the techniques for a selective separation and rejection of typical associated minerals in the iron oxide ores, such as phosphorous minerals (mainly apatite group), is a high priority Reverse anionic flotation by using sodium silicate (SS) as an iron oxide depressant is one of the Selective Separation of Hematite by a Synthesized Reagent Co, 99%) stepbystep; the obtained precursor solution was then stirred overnight The LaFeO 3 layer was prepared onto the surface of the hematite photoanode by a spincoating method at 3000rpm for 30s and then annealed at 400°C for 5min in air The spincoating process was carried out for one or two cycles for different samples Improved charge separation efficiency of hematite

hematite iron step hitlershollywoodde

Hematite separation process step by step Henan Mining Classification step iron ore hematite Mining May 10 2013Thus fine hematite and goethite particles are usually not recovered resulting in the loss of valuable iron ore fines initiating steps to utilize the low grade iron ores fines and slimes the slime using classification followed by Beneficiation Process Of Iron Ore Hematite Dry Separation Beneficiation Process Of Iron Ore Hematite Dry Separation As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc we offer advanced, rational solutions for any size reduction requirements, including quarry, aggregate, grinding productionplete plant plan「beneficiation process of iron ore hematite dry Process water is used to assist the separation process The heaviest particles are separated from finer particles by centrifugal force A collector at the bottom of each spiral collects the heavy concentrate (socalled hematite concentrate) and eliminates the lighter unwanted particles (middlings and tails) This step is repeated two or three The Six Main Steps of Iron Ore Processing Multotec

iron ore hematite mining process

steps of mining hematite on lower section of the preassessment and focus question Folded File Folder page 3 Pass out Iron Ore Process page and have students fill in all steps of the iron ore process Option – have students draw and color a picture with each step in the process 4 Pass out Persuasive letter instruction and rubric pageIndonesia hematite flotation separation process hematite separation process is suitable for complex structure hematite such as,combined process of magnetic flotation separation,,a hematite in philippines chat now hematite separation process step by step ccsindiain get price separation process of separation sand flotation Blumen Atelier Geiger Hematite electrodes with variable morphologies were prepared via a simple electrodeposition (ED) method The photoelectrochemical (PEC) properties of planar and nanostructured electrodes were examined under PEC water oxidation and compared to that of planar analogue prepared by atomic layer deposition (ALD) The water oxidation performance of electrodeposited planar thin films was Enhanced Charge Separation and Collection in High

Hydrogen Reduction of Hematite Ore Fines to

Surplus coke oven gases (COGs) and low grade hematite ores are abundant in Shanxi, China Our group proposes a new process that could simultaneously enrich CH 4 from COG and produce separated magnetite from low grade hematite In this work, lowtemperature hydrogen reduction of hematite ore fines was performed in a fixedbed reactor with a stirring apparatus, and a laboratory Davis magnetic We report that metal ions (M: Sn4+ and Ti4+) and boroncodoped hematite photoanodes with an n–n+ homojunction showed significantly increased photoelectrochemical (PEC) water splitting activity with greatly reduced surface recombination The secondary Bdoping of broadly used Mdoped hematite photoanodes not only suppresses the number of M+ ions, which inevitably cause Boron Doping of MetalDoped Hematite for Reduced