عنا

مرحبا هل يمكنني مساعدتك؟

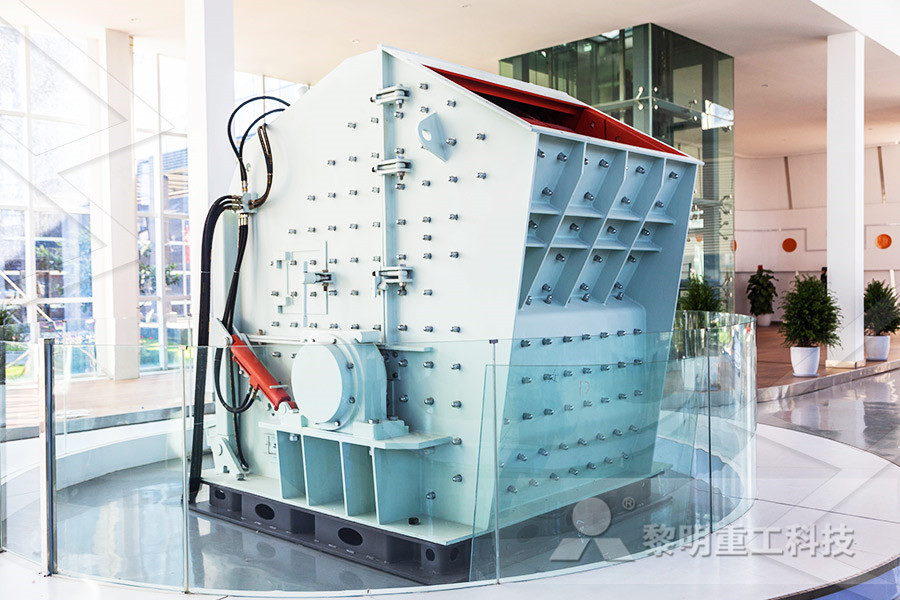

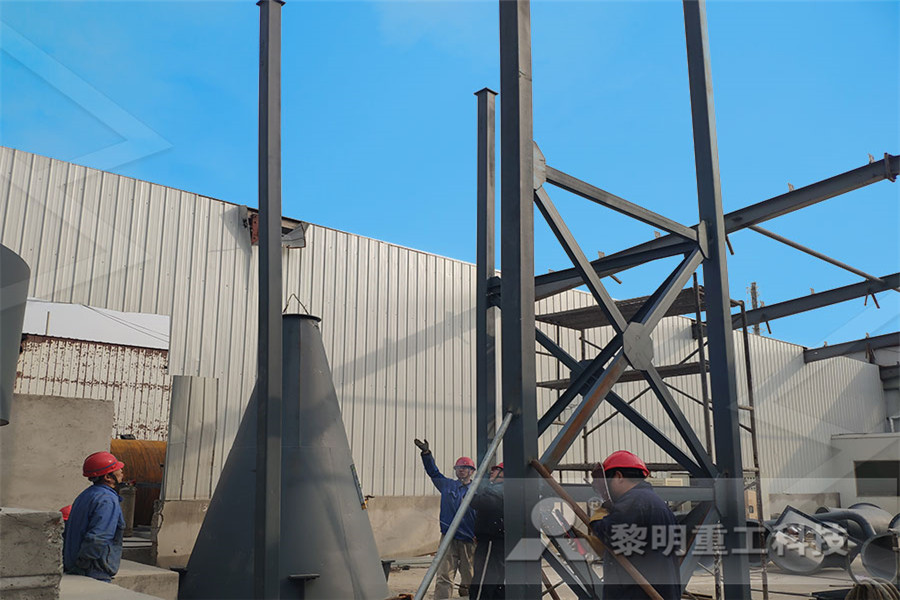

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Operation Process Grinding

2020-10-28T11:10:13+00:00

Grinding Operation an overview ScienceDirect Topics

For surface grinding operations, the process parameters, ie the linear feed, the cross feed, and the depth of cut, have a direct influence on the roughness of the ground surface Higher values of any of them would result in a higher material removal rate, and therefore, a Grinding Process Grinding is a surface finishing operation where very thin layer of material is removed in the form of dust particles Thickness of material removed is in range of 025 to 050 mm Tool used is a abrasive wheel Grinding machine is a power operated machine tool where, the work piece is fedGRINDING PROCESSOre Processing Challenges in Gold Operation Grinding Circuits By Scott Ferguson 06162020 Continuous control of the final grinding product size is important to optimize gold liberation for gold milling operations In addition, the live monitoring of the final product particle size leads to a maximum grinding circuit throughputOre Processing Challenges in Gold Operation

QUALITY IMPROVEMENT OF A GRINDING OPERATION

76 Int J Mech Eng Rob Res 2012 J Praveen Kumar et al, 2012 QUALITY IMPROVEMENT OF A GRINDING OPERATION USING PROCESS CAPABILITY STUDIES J Praveen Kumar 1*, B Indhirajith and K Thiruppathi1 *Corresponding Author: J Praveen Kumar, jpmech1603@gmail Quality is a state of a finished product, being free from defects, deficiencies Grinding Process Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool 6 Surface Grinding Surface grinding uses a rotating abrasive wheel to remove material, creating a flat surface 7Grinding operation SlideShare This process is known as Dressing of grinding wheel and the whole process takes 15 to 20 minutes to operate The life of the grinding wheel is described as the time period between two successive dressings Grinding operation is one of the machining Grinding Machining Process : Complete Notes

Crushing and Grinding Process JXSC Machine

The grinding process is the final operation of making the mineral to dissociate from the monomer and making the particle size meet the selection requirements Grinding is a highefficiency and lowefficiency operation grinding processes Grinding is the most common form of abrasive machining It is a material cutting process which engages an abrasive tool whose cutting elements are grains of abrasive material known as grit These grits are characterized by sharp cutting points, high hot hardness, and chemical stability and wear resistance The grits areCHAPTER 1 INTRODUCTION TO GRINDING Grinding – Ex 11 • You are grinding a steel, which has a specific grinding energy (u) of 35 Ws/mm3 • The grinding wheel rotates at 3600 rpm, has a diameter (D) of 150 mm, thickness (b) of 25 mm, and (c) 5 grains per mm2 The motor has a power of 2 kW • The work piece moves (v) at 15 m/min The chip thickness ratio (r) is 10Grinding and Finishing IIT Bombay

QUALITY IMPROVEMENT OF A GRINDING OPERATION

Process Control are the charts, where the average, range, standard deviations, process capability values can be determined by statistical approach These tools use the Process Capability index value as a major technique to verify whether any variations occurred on the grinding operation or not (Gijo, 2005) Process Capability Calculation Quality is a state of a finished product, being free from defects, deficiencies and significant variations This measure of an excellence can be brought about by the strict and consistent adherence to measureable and verifiable standards to achieve uniformity of output that satisfies specific customer or user requirements This paper gives a proposed methodology for to increase the quality of QUALITY IMPROVEMENT OF A GRINDING The grinding process and mill operation Progress is our tradition MPS vertical roller mill MVR vertical roller mill TP/ Ne 08 / 04 PFEIFFER Vertical roller mills for the cement industry GEBR PFEIFFER Unchanged Changed / Improved Grinding Process and Operation Cement Mill

traininggovau FDFOP2038A Operate a grinding

1 Prepare the grinding equipment and process for operation 11 Materials are confirmed and available to meet production requirements 12 Cleaning and maintenance requirements and status are identified and confirmed 13 Machine components and related attachments are fitted and adjusted to meet operating requirements 14Grinding is machining process that’s used to remove material from a workpiece via a grinding wheel As the grinding wheel turns, it cuts material off the workpiece while creating a smooth surface texture in the process While grinding sounds simple enough, there are probably some things you don’t know about this machining process5 Facts About Grinding Processes Monroe Engineering Grinding is an operation applied in almost every type of manufacturing process It aims to produce high surface finish and to maintain close tolerances in the manufactured product To make the grinding operation more productive and efficient, dressing and truing operations are performed on the grinding wheels VariousREVIEW OF DRESSING AND TRUING OPERATIONS FOR

Grinding Machine [Grinding Wheel, Types,

The grinding process is truly a chip producing machining process The rough surface of the abrasive wheel spreads into small portions of the workpiece as required It is also known as a grinder The grinding process is capable of producing very accurate sizes, equally accurate geometry like flatness or circle and extremely good surface finish various types of grinding process in our previous post, where we have discussed each grinding process in detail We have also discussed basic principle of grinding in our previous post, where we have seen the basics of grinding process and various abrasives materials as well as we have also noted the various factors affecting the quality of object surface created by grinding processAPPLICATIONS AND ADVANTAGES OF GRINDING Grinding – Ex 11 • You are grinding a steel, which has a specific grinding energy (u) of 35 Ws/mm3 • The grinding wheel rotates at 3600 rpm, has a diameter (D) of 150 mm, thickness (b) of 25 mm, and (c) 5 grains per mm2 The motor has a power of 2 kW • The work piece moves (v) at 15 m/min The chip thickness ratio (r) is 10Grinding and Finishing IIT Bombay

Centerless Grinding an overview ScienceDirect Topics

Fine grinding is performed on a lapping machine with bonded grinding wheels, providing advantages over the lapping process, including more speed, better accuracy, and cleaner parts Fine grinding is faster than the lapping operation, which will reduce the operating costProcess Control are the charts, where the average, range, standard deviations, process capability values can be determined by statistical approach These tools use the Process Capability index value as a major technique to verify whether any variations occurred on the grinding operation or not (Gijo, 2005) Process Capability CalculationQUALITY IMPROVEMENT OF A GRINDING OPERATION 1 Prepare the grinding equipment and process for operation 11 Materials are confirmed and available to meet production requirements 12 Cleaning and maintenance requirements and status are identified and confirmed 13 Machine components and related attachments are fitted and adjusted to meet operating requirements 14traininggovau FDFOP2038A Operate a grinding

Grinding safety operation Procedure图文百度文库

Supervise grinding operation to meet the safety hygiene requirements a 作业前必须对重要设备进行粉尘防护; Must prevent important equipments from dust before work b 作业区域应停止不相容作业,并消除遗留的危险因素; Should stop irrelative operation in the working area and eliminate the rudimental dangerous factors Quality is a state of a finished product, being free from defects, deficiencies and significant variations This measure of an excellence can be brought about by the strict and consistent adherence to measureable and verifiable standards to achieve uniformity of output that satisfies specific customer or user requirements This paper gives a proposed methodology for to increase the quality of QUALITY IMPROVEMENT OF A GRINDING Grinding is the most common form of abrasive machining It is a material cutting process which engages an abrasive tool whose cutting elements are grains of abrasive material known as grit These grits are characterized by sharp cutting operation are called active grains In peripheral grinding , each active grain remove a CHAPTER 1 INTRODUCTION TO GRINDING

Grinding Process Dominance by Means of the

Summary This work shows a way to dominate the grinding process through the dressing operation The influence of dressing upon the grinding process performance is investigated regarding to the metal removal rate, surface roughness, cutting forces during the grinding wheel life GRINDING MACHINES Grinding is the process of removing metal by the application provided for safety and ease of operation Grinding machines grinding on either the periphery or side of the wheel Tapered Tapered wheels, type number 4, take tapered safety flangesGRINDING MACHINES irem sen various types of grinding process in our previous post, where we have discussed each grinding process in detail We have also discussed basic principle of grinding in our previous post, where we have seen the basics of grinding process and various abrasives materials as well as we have also noted the various factors affecting the quality of object surface created by grinding processAPPLICATIONS AND ADVANTAGES OF GRINDING

Automatic control system of grinding process IEEE

The grinding processes in mineral processing plants are characterized by nonlinearity, timevariability, with large inertia Furthermore, their boundary conditions often change during operation, and technical indexes such as grinding particle size are difficult to measure online, and optimizing control is difficult to achieve These often result in unstable operation, so the product quality Grinding – Ex 11 • You are grinding a steel, which has a specific grinding energy (u) of 35 Ws/mm3 • The grinding wheel rotates at 3600 rpm, has a diameter (D) of 150 mm, thickness (b) of 25 mm, and (c) 5 grains per mm2 The motor has a power of 2 kW • The work piece moves (v) at 15 m/min The chip thickness ratio (r) is 10Grinding and Finishing IIT Bombay