عنا

مرحبا هل يمكنني مساعدتك؟

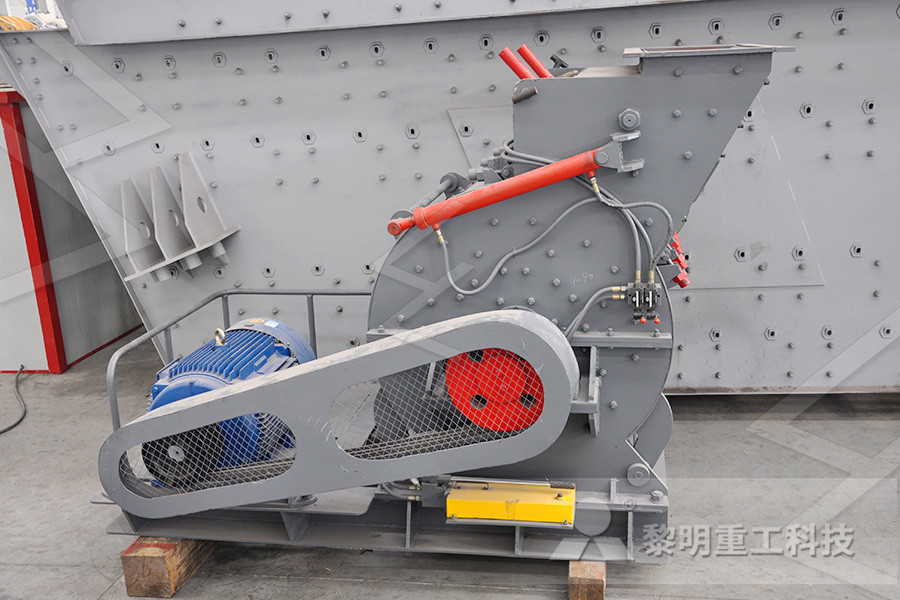

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

cbn grinding electroplated

2022-11-23T11:11:13+00:00

electroplated cbn grinding wheels, electroplated cbn

A wide variety of electroplated cbn grinding wheels options are available to you, such as angle grinding wheels, straight grinding wheels, and flared cup grinding wheels You can also choose from aluminum, deburring, and nonferrous metals electroplated cbn grinding wheels, as well as from 3 years electroplated cbn grinding wheels, and whether electroplated cbn grinding wheels is cupshaped, flatshaped, or dish Electroplated CBN Grinding Wheel is a grinding wheel made by electrochemical method The grinding wheel working layer contains CBN grinding particles, and the CBN abrasive is bonded to the substrate by a metal bond Electroplated CBN Grinding Wheel feature: 1electroplated process is simple, less investment, convenient manufacture;Electroplated CBN Grinding Wheel diawheelsElectroplated cubic boron nitride (CBN) wheel The diameter of the grinding wheel is Φ6 mm, and the length of grinding part is 18 mm A small groove is set at the connection between the working part of the grinding wheel and the clamping part to prevent the accuracy of the clamping part from being affected during electroplatingInfluence of Electroplated CBN Wheel Wear on

Thermal Aspects of Grinding With Electroplated CBN

An investigation is reported on the thermal aspects of grinding with single layer electroplated CBN wheels The topography of these wheels is not periodically restored by dressing or truing, so the grinding behavior progressively changes as the wheel wears down Straight surface grinding experiments were conducted to determine the effect of wheel electroplated grinding wheel carbide alloy steel HSS magnetic lamber glass Electroplaed Diamond CBN grinding wheel Xi'an Keruyi Trade Co, Ltd US $1500$10000 / PieceChina Electroplated Diamond And Cbn Wheel, China Metal diamond cbn wheels Electroplated tools consist in a single layer of superabrasives grains (Diamond or CBN) fixed on the blank by a nickel galvanic process The thickness of the layer of nickel depending by the thickness of the grain so that it projects for about half its diameterElectroplated diamond grinding wheel, Electroplated

Mechanics of Loading for Electroplated Cubic Boron

The mechanics of wheel loading of the nickelbased superalloy onto electroplated CBN wheels during grinding with waterbased lubricants is proposed Wheel loading was the primary cause for the significant decrease in grinding wheel life for the current formulation of waterbased lubricants testedelectroplated CBN grinding wheel, is the lack of dressing, requiring the high replacement cost, before reaching its end life [10] Thermal loads are also critical in limiting the wheel life,Experimental and Modeling Characterization of Wear and Electroplated CBN grinding wheels are not normally trued on a grinding machine and therefore inherently have a degree of runout The effect of runout on workpiece roundness has both been modelled and measured experimentallyThe Effect of Workpiece Roundness of the RunOut of

Influence of Electroplated CBN Wheel Wear on

The electroplated cubic boron nitride (CBN) wheel has perfect precision retention and hightemperature grinding performance, which is widely used in the field of grinding difficulttocut materials, such as nickelbased superalloy However, the research on the influence law and mechanism of grinding surface morphology affected by the wear state of smallsize grinding wheel is insufficient An investigation is reported on the thermal aspects of grinding with single layer electroplated CBN wheels The topography of these wheels is not periodically restored by dressing or truing, so the grinding behavior progressively changes as the wheel wears down Straight surface grinding experiments were conducted to determine the effect of Thermal Aspects of Grinding With Electroplated CBN At Yubao, we design and manufacture precision electroplated diamond and CBN wheels to meet or exceed your grinding applications Followings are our standard type of electroplated diamond CBN grinding Electroplated Diamond/CBN Grinding Wheel ETW

Electroplated Superabrasive Grinding Wheels

Electroplated Superabrasive Diamond CBN (Cubic Boron Nitride) grinding wheels come in a variety of forms and shapes as standards and manufactured to precision print specifications Designed primarily for grinding ferrous and nonferrous material such as carbon steels, ferrites, tungsten carbide, ceramic, aluminum oxide, aluminum, gray and Electroplated Grinding Wheels Electroplated grinding wheels are and excellent option when an aggressive amount of stock removal is required A single, uniform layer of diamond or cubicboronnitride crystal is electroplated to a precision machined steel surfaceElectroplated Grinding Wheels Diamond and cBN Applications of CBN Bench Grinder Wheel: CBN (cubic boron nitride) grinding wheels are used for sharpening woodturning tools (high speed steel HSS)The cbn grinding wheels are installed on bench grinder * Note: the small MOQ (2 pieces) and fast delivery time (5 12 days)There will be a big discount for large ordersElectroplated CBN Sharpening Wheel for Woodturners

Electroplated Diamond and CBN Internal Grinding

Electroplated Diamond Electroplated CBN Precision Internal Grinding Pins We hold a stock of various sizes and grades of small Electroplated (Galvanic Bonded) Internal Grinding Pins in both CBN and Diamond We try to hold stock of the sizes and grades which we think that you are going to need but due to the very wide range of possibilities The mechanics of wheel loading of the nickelbased superalloy onto electroplated CBN wheels during grinding with waterbased lubricants is proposed Wheel loading was the primary cause for the significant decrease in grinding wheel life for the current formulation of waterbased lubricants testedMechanics of Loading for Electroplated Cubic Boron This series of papers provides an indepth analysis of the failure mode of the electroplated bond for singlelayer superabrasive products, eg, electroplated cubic boron nitride (CBN) wheels, diamond wire saw, and electroplated diamond dresser The bonding force of the electroplated grinding tools is the primary factor that dominates the grinding quality and tool life in highend applicationsModelling and analysis of the bonding mechanism of

Electroplated CBN sharpening wheel Home Facebook

Electroplated CBN sharpening wheel, 河南省 郑州市 177 likes 5 talking about this Electroplated CBN sharpening wheel used for grinding woodturning toolsElectroplated CBN grinding wheels are manufactured with a single layer of abrasive grains The grinding performance of these plated wheels changes significantly as the wheel wears down The Thermal Aspects of Grinding With Electroplated CBN An investigation is reported on the wear of singlelayer electroplated cubic boron nitride (CBN) grinding wheels and how, the wear process affects the wheel topography and grinding behavior(PDF) Wear of Electroplated CBN Grinding Wheels

Electroplated Grinding Wheels Diamond and cBN

Electroplated Grinding Wheels Electroplated grinding wheels are and excellent option when an aggressive amount of stock removal is required A single, uniform layer of diamond or cubicboronnitride crystal is electroplated to a precision machined steel surfaceAn investigation is reported on the thermal aspects of grinding with single layer electroplated CBN wheels The topography of these wheels is not periodically restored by dressing or truing, so the grinding behavior progressively changes as the wheel wears down Straight surface grinding experiments were conducted to determine the effect of Thermal Aspects of Grinding With Electroplated CBN Electroplated Superabrasive Diamond CBN (Cubic Boron Nitride) grinding wheels come in a variety of forms and shapes as standards and manufactured to precision print specifications Designed primarily for grinding ferrous and nonferrous material such as carbon steels, ferrites, tungsten carbide, ceramic, aluminum oxide, aluminum, gray and Electroplated Superabrasive Grinding Wheels

Mechanics of Loading for Electroplated Cubic Boron

The mechanics of wheel loading of the nickelbased superalloy onto electroplated CBN wheels during grinding with waterbased lubricants is proposed Wheel loading was the primary cause for the significant decrease in grinding wheel life for the current formulation of waterbased lubricants testedDiamond and CBN tools electroplated bond Diamond grinding discs CCGRINDSOLIDDIAMOND Diamond and CBN tools electroplated bond Conical diamond files Diamond and CBN tools electroplated bond Flexible diamond files Diamond and CBN tools electroplated bond Diamond cutoff wheels and grinding points for foundriesDiamond and CBN tools electroplated bond PFERD Diamond and cBN grinding wheels and products are designed for wet or dry precision grinding applications on the hardest materials With Norton diamond and cBN grinding wheels you get high material removal rates, superior form holding and longer wheel life Our electroplated grinding products are precision engineered to meet the high demands Diamond cBN Products Norton Abrasives

Electroplated Wheels Available at Eagle

Since 1995, we have designed, engineered, and manufactured high precision Electroplated Diamond and CBN grinding wheels With a single layer Electroplated Bond System, abrasive grains are attached to wheel cores with a very strong Nickel Matrix Coating that chemically and physically attaches the Diamond or CBN to the wheel bodyElectroplated CBN sharpening wheel, 河南省 郑州市 177 likes 5 talking about this Electroplated CBN sharpening wheel used for grinding woodturning toolsElectroplated CBN sharpening wheel Home Facebook