عنا

مرحبا هل يمكنني مساعدتك؟

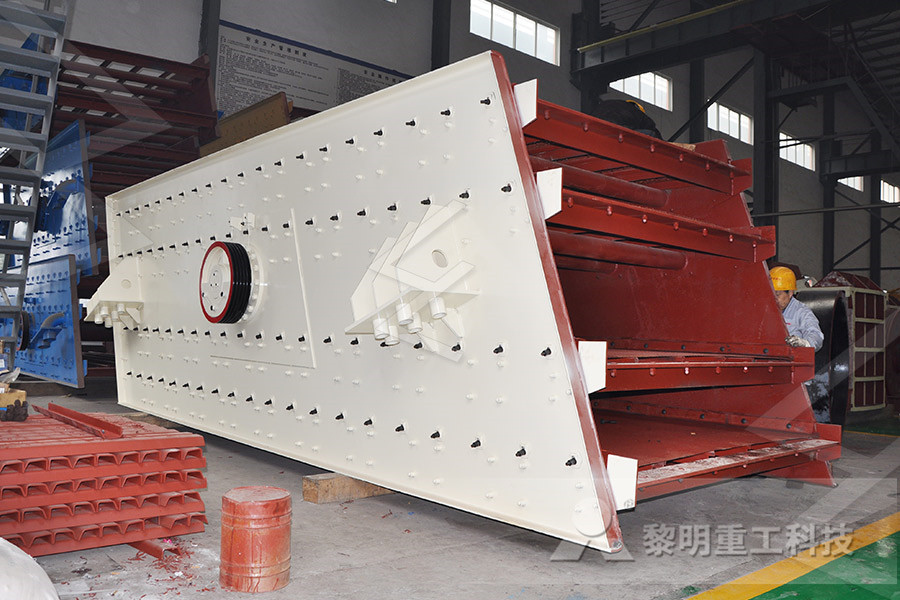

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

selection of sendary and reduction crushers

2021-06-22T14:06:48+00:00

Criteria of design and selection of a crusher machine

These steps of size reduction are called “primary, secondary, tertiary, and quaternary Depending on the rock nature and the capacity, the feed and discharge sizes (especially the size of the larger blocks), we can design and choose the suitable crushers Elements of the choice of primary crusherreduction ratio of line crusher Knock Heavy Usually these line crushers' reduction ratio is10~35The line Jaw Crusher is widely used in mining Enquiry Price Specific types Stone crusher JBS Crusher Many different types of stone crusher stone crushing production line are often used in the stone crusher with crushing ratio even granularity simple structurereduction ratio of secondary crushersHorizontal shaft impact crushers can be primary or secondaryThey are better suited for softer, less abrasive stone in the primary stage and more abrasive and harder stone in the secondary stageSelection of rock crushing equipmentChoosing the right rock crusher is based on different factors and these include ore parison Between Primary And Secondary Crusher

Selecting the right crusher : Pit Quarry

Understanding the stages of crushing and the types of crushers that best fit each stage simplifies equipment selection Each type of crusher is different and used to achieve a certain end result Similarly, a certain output is expected at the end of each Selection Of Primary Crushers Sep 27, 2019nbspa primary crusher is the driving force of the success of your plant here is what a successful process of choosing a primary crusher looks like one should begin with crusher purpose, move to model refinement, and finish with a successful installationSelection Of Primary Crushers buddymobilde They are compression crushers that generally provide reduction ratios of 6to1 to 4to1 Cone crushers are used in secondary, tertiary and quaternary stages With proper chokefeed, conespeed and reductionratio settings, cone crushers will efficiently produce material that is high quality and cubical in naturePQ University Lesson 7 Crushing Secondary

Impact Crushers Primary McLanahan

McLanahan offers a wide selection of Impact Crushers for quarried limestone and semiabrasive minerals McLanahan draws from the 75 years of field experience with the Universal line of Impactors, which includes impact breakers and Andreasstyle A 4:1 ratio of reduction of feed to product size is considered when making crusher selection As with other crushers, the feed size normally determines the roll diameter and width of the sizer However, an exception to this rule is sometimes How Do I Know Which Primary Crusher Is Best For My Now a secondary crusher comes into action and further reduces the size In secondary crusher some sizes of stones may pass directly from sieve number 4 Examples of secondary crushers are cone crusher, roll crusher and hammer mill crusherCrusher Definition Crusher Selection And Types of

101 Guide: Proper Selection of Industrial plastic crushers

Other than used for secondary size reduction, they’re also utilized to crush and clean material if add a water sprinkler system In this article, we show you how to choose plastic crushers 1 How to Feed There 3 ways of feed a crusher by hands, by conveyor and by forkliftreduction impact crusher Big Reduction Ratio Reversible Impact Hammer Crusher reduction ratio of secondary crushers xcellence Secondary impact crusher rock crusher reduction ratio of secondary crushers Large feed opening cubic products high reduction ratio high capacity low investment and operating cost are some of the features which make these crushers idealrock crusher types and reduction ratios Understanding the stages of crushing and the types of crushers that best fit each stage simplifies equipment selection Each type of crusher is different and used to achieve a certain end result Similarly, a certain output is expected at the end of each crushing stage for the next phase of the processSelecting the right crusher : Pit Quarry

Cone Crusher Liners: How to Select and When to

Cone Crushers were developed more than a century ago to provide secondary, tertiary and even quaternary material reduction Like other compression crushers, Cone Crushers feature a crushing chamber or cavity where the rock is crushed to a smaller sizeThe crushing chamber in a Cone Crusher is the space created between the mantle (the moving piece of steel) and concaves (the stationary piece Jaw crushers are reliable, robust machines, offering a 6:1 reduction ratio in most materials, and will accommodate hard, abrasive materials Roll crushers – Roll crushers are a compressiontype reduction crusher with a long history of success in a broad range of applications The crushing chamber is formed by massive drums, revolving towards Selecting the right type of crushing equipment – QuarrySecondary crushers are normally of the cone or gyratory type Tertiary and final Every single reduction step is described by a selection and a breaka ge function The flow(PDF) Cone Crusher Performance ResearchGate

crushing circuit selection and sizing of crusher

14 Sep 2011 The correct selection between all alternatives is a difficult problem [13 world use the procedure as a component of comminution circuit design and to Jaw crushers are most commonly defined by gape size, open andThe gyratory crushers crush to reduce the size by a maximum of about onetenth its size Usually, metallurgical operations require greater size reduction; hence, the products from the primary crushers are conveyed to secondary or cone crushers where further reduction in size takes place Here, the maximum reduction ratio is about 8:1Gyratory Crusher an overview ScienceDirect TopicsThe three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 44)A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 44(a)) and it is the most widely used in primary crushing stages (Behera et al, 2014)Impact Crusher an overview ScienceDirect Topics

Crusher Definition Crusher Selection And Types of

Now a secondary crusher comes into action and further reduces the size In secondary crusher some sizes of stones may pass directly from sieve number 4 Examples of secondary crushers are cone crusher, roll crusher and hammer mill crusherEquipment Selection For Crushing Plant Jaw crushers are most commonly used as primary crushers, to make the first step of size reduction, and used to prepare the feed for the secondary crusher in a crushing and screening process Jaw crushers can crush kinds of hard rocks in the worst environmentEquipment Selection For Crushing Plant Yeco Selection Of Primary Crushers The selection of the primary crusher the selection of the primary crusher the selection of the primary crusher is the key to the success of any operation that involves size reduction each of the various types of primary crushers is discussed the material hardness impact strength and abrasive index define which Selection Of Primary Crushers Crusher Mechanic

Selecting the right crusher : Pit Quarry

Understanding the stages of crushing and the types of crushers that best fit each stage simplifies equipment selection Each type of crusher is different and used to achieve a certain end result Similarly, a certain output is expected at the end of each crushing stage for the next phase of the processSecondary crushers are normally of the cone or gyratory type Tertiary and final Every single reduction step is described by a selection and a breaka ge function The flow(PDF) Cone Crusher Performance ResearchGate Jaw crushers are reliable, robust machines, offering a 6:1 reduction ratio in most materials, and will accommodate hard, abrasive materials Roll crushers – Roll crushers are a compressiontype reduction crusher with a long history of success in a broad range of applications The crushing chamber is formed by massive drums, revolving towards Selecting the right type of crushing equipment – Quarry

crushing circuit selection and sizing of crusher

14 Sep 2011 The correct selection between all alternatives is a difficult problem [13 world use the procedure as a component of comminution circuit design and to Jaw crushers are most commonly defined by gape size, open and CRUSHERS Secondary crusher reduces lumps into 6 mm Primary crusher accepts anything from mine breaks into 150 250 mm • Slowspeed machine for coarse reduction of large quantities of solids main types: 1) Jaw crushers 2) Gyratory crushers 3) smoothroll crushers 4) toothedroll crushers Gyratory crusherSIZE REDUCTION Universiti Teknologi Malaysiaungwon Magnetics as a sole agent of Terrasource Global USA (Pennsylvania Crushers + Gundlach + Jeffrey Rader) who is a top manufacturer of various kinds of crushers, specially coal crushers in the world is suppling coal crushers etc to most of power plants in Korea and to plant engineering companies, Samsung Engineering, Hyundai EC, LG Construction, SK EC, Daelim EC, Doosan Heavy, Sungwon Magnetics CRUSHERS

(PDF) SIZE REDUCTION BY CRUSHING METHODS

Size Reduction is mainly done through crushers and mills Crushing and grinding are the two primary comminution processes Crushing is normally carried out on the "runofm ine" ore