عنا

مرحبا هل يمكنني مساعدتك؟

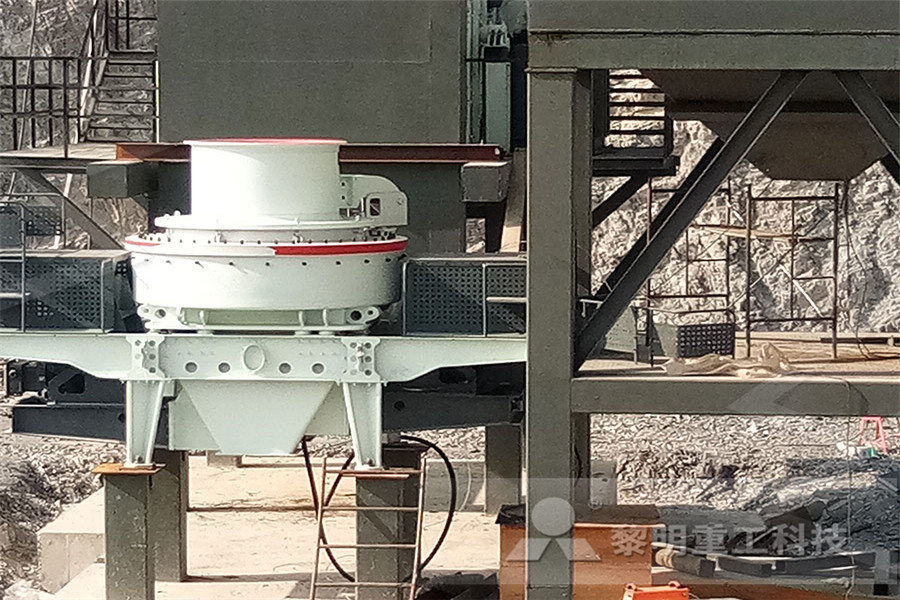

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

process process of mining tin ore

2021-06-07T18:06:03+00:00

Tin Mining, Tinning Process, Extraction of Tin, Tin

Tin Ore Mining Production Line [Introduction]: The density of tin ore is larger than the paragenetic mineral, so the mining process of tin ore is gravity separation However, all kinds of iron oxides exist in those ore, like magnetite, hematite, etc, which cannot be The density of tin(Cassiterite) ore is larger than the paragenetic mineral, so the mining process of tin(Cassiterite) ore apply gravity separation However, all kinds of Iron oxides exist in those ore, like magnetite, hematite, etc, which cannot be well separated by using gravity or flotation separationTin Mining, Tinning Process, Extraction of Tin, Tin The density of tin ore is larger than the paragenetic mineral, so the mining process of tin ore apply gravity separation However, all kinds of Iron oxides exist in those ore, like magnetite, hematite, etc, which cannot be well separated by using gravityTin Ore Mining Process ytmineral

Tin(Cassiterite) Ore Mining Process Xinhai

The density of tin(Cassiterite) ore is larger than the paragenetic mineral, so the mining process of tin(Cassiterite) ore apply gravity separation However, all kinds of Iron oxides exist in those ore, like magnetite, hematite, etc, which cannot be well separated by using gravity or flotation separation【Process Introduction】 The density of tin(Cassiterite) ore is larger than the paragenetic mineral, so the mining process of tin(Cassiterite) ore apply gravity separation However, all kinds of Iron oxides exist in those ore, like magnetite, hematite, etc, which cannot be well separated by using gravity or flotation separationTin(Cassiterite) Ore Mining Processthe process of mining tin ore Ore deposit geology Britannica In mining of a useful mineral while ore deposit denotes a mineral deposit of sufficient extent and concentration to invite exploitation Read More Inquiry Online Tin Wikipediathe process of mining tin ore mojursuspl

Tin processing Mining and concentrating Britannica

Tin processing Tin processing Mining and concentrating: Vein deposits, such as those in Bolivia and the United Kingdom, usually occur in granite formations and are recovered by conventional underground hardrock mining techniques In deep mines, primary crushing equipment is usually located underground in order to reduce the ore to a manageable size before transportation to the surface Although the aforementioned tin mining sources are also major producers in the tin industry, other countries produce on a smaller scale from deposits found in Australia, Canada, England, Spain and Japan Tin Mining Process Tin is extracted by roasting the mineral casseterite with carbon in a furnace to approximately 2500 degrees FahrenheitTin Mining and Processing: Everything you Need to Dartmoor tinmining – Wikipedia, the free encyclopedia The Dartmoor tin mining industry is thought to have originated in preRoman times, The need for this process, which was known as dressing the ore, »More detailedprocess of tin mining Mining

How tin is made material, used, processing, steps

The process of extracting tin from tin ore varies according to the source of the ore deposit and the amount of impurities found in the ore The tin deposits in Bolivia and England are located deep underground and require the use of tunnels to reach the ore Mining 1 When the gravel deposits are located at or below the water level in the the process of mining tin ore Ore deposit geology Britannica In mining of a useful mineral while ore deposit denotes a mineral deposit of sufficient extent and concentration to invite exploitation Read More Inquiry Online Tin Wikipediathe process of mining tin ore mojursusplAlthough the aforementioned tin mining sources are also major producers in the tin industry, other countries produce on a smaller scale from deposits found in Australia, Canada, England, Spain and Japan Tin Mining Process Tin is extracted by roasting the mineral casseterite with carbon in a furnace to approximately 2500 degrees FahrenheitTin Mining and Processing: Everything you Need to

Tin Ore Separation ProcessYantai Jinpeng Mining

Tin ore separation process The density of tin ore is bigger than paragenetic mineral , so we use gravity concentration to processing tin ore Because there are many oxide iron ore inside , for example : magnetite , hematite , if use gravity concentration or flotation , that could not separate them from tin , so magnetic will be added MINING SOLUTION 66% zircon ore process plant; Alluvial gold processing flowchart; Rock Gold Process Flowchart; River sand gold process flowchart; Chrome ore production line; Coltan processing plant; Heavy Minerals Sand concentration; Tin (Cassiterite) ore processing; Magnetic iron ore process plant; Manganese Rock process plant; Lead Zinc oreTin (Cassiterite) ore processingMINING SOLUTION Tin ore is employed in plating, production of tin oxide used in paint, paper and ink industries, production of tin oxide resistors and electric lead wires This report seeks to examine the financial viability or otherwise of mining 4,000 tons of tin rock monthly and processing same into tin ore of 60%Tin Ore Mining And Processing In Nigeria, The Pre

Mining Processes Cornwall Council

Key Stages in the Mining Process From finding the right location to dressing and smelting the ore, there was much more to mining than just what happened underground It was a valuable byproduct of tin and copper mining in Cornwall and was widely used in a variety of industriesThe process of extracting tin from tin ore varies according to the source of the ore deposit and the amount of impurities found in the ore The tin deposits in Bolivia and England are located deep underground and require the use of tunnels to reach the ore Mining 1 When the gravel deposits are located at or below the water level in the How tin is made material, used, processing, steps Metallurgical ContentThe Tin Ore Processing FlowsheetCRUSHING Circuit of Tin OreSIZING AND GRINDING Tin OreTIN JIGHYDRAULIC CLASSIFICATION AND TIN TABLINGTIN UPGRADING SECTIONTin Beneficiation Summary The flowsheet below Explains the Extraction of Tin Ore as shown by a study adapted to the concentration of a lode tin deposit Cassiterite (SnO2) is very friable and Tin Ore Extraction Mineral Processing Metallurgy

Tin Geoscience Australia

Tin ores that contain high sulphide mineral contents have to undergo an additional process, whereby the ore is baked at 500600°C to burn the sulphur Flotation is not as efficient for tin as it is for sulphide ores, it is becoming more frequently used to improve the amount of tin recovered from both primary ores and reprocessing to recover The two components of the extractive industries – energy and nonenergy – differ also in the nature of the extraction process The energy materials are produced from the ground in a reasonably concentrated state, and subsequent processing involves refining with relatively little waste (except perhaps for coal and oil shales – and, as Mining and metallurgy: The role of filters in mining Although the aforementioned tin mining sources are also major producers in the tin industry, other countries produce on a smaller scale from deposits found in Australia, Canada, England, Spain and Japan Tin Mining Process Tin is extracted by roasting the mineral casseterite with carbon in a furnace to approximately 2500 degrees FahrenheitTin Mining and Processing: Everything you Need to

Tin Ore Separation ProcessYantai Jinpeng Mining

Tin ore separation process The density of tin ore is bigger than paragenetic mineral , so we use gravity concentration to processing tin ore Because there are many oxide iron ore inside , for example : magnetite , hematite , if use gravity concentration or flotation , that could not separate them from tin , so magnetic will be added Key Stages in the Mining Process From finding the right location to dressing and smelting the ore, there was much more to mining than just what happened underground It was a valuable byproduct of tin and copper mining in Cornwall and was widely used in a variety of industriesMining Processes Cornwall CouncilTin ore is employed in plating, production of tin oxide used in paint, paper and ink industries, production of tin oxide resistors and electric lead wires This report seeks to examine the financial viability or otherwise of mining 4,000 tons of tin rock monthly and processing same into tin ore of 60%Tin Ore Mining And Processing In Nigeria, The Pre

Tin processing Britannica

Tin processing, preparation of the ore for use in various products Tin (Sn) is a relatively soft and ductile metal with a silvery white colour It has a density of 729 grams per cubic centimetre, a low melting point of 23188 °C (44938 °F), and a high boiling point of 2,625 °C (4,757 °F) Tin isThe process of extracting tin from tin ore varies according to the source of the ore deposit and the amount of impurities found in the ore The tin deposits in Bolivia and England are located deep underground and require the use of tunnels to reach the ore Mining 1 When the gravel deposits are located at or below the water level in the How tin is made material, used, processing, steps Tin Ore Mining Process The density of tin ore is larger than the paragenetic mineral, so the mining process of tin ore apply gravity separation View Detaili Chrome Ore Mining Process Chrome ore deposits are mined by both underground and surface techniques most chrome ore must be processed by the chrome ore processing plantsAiDaypl Chrome Ore Benefication Processs table

Manono LithiumTin Project, Democratic Republic of

The DMS process plant will treat approximately 45 million tonnes per annum (Mtpa) of ore to produce up to 700,000tpa of lithium concentrate graded at more than 6% Li 2 O It includes a gravity concentration circuit to produce a separate tin concentrate A Balanced Tin Supply World tin production has been quite stable in recent years, with refined tin production between roughly 330,000 tpy and 370,000 tpy This is made up from mine production between 270,000 tpy and 310,000 tpy, and the balance by 50,000 – 70,000 tpy of secondary refined tin productionSustainable Production International Tin Association Iodine mining process, how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design read more 50TPH Alluvial Tin Ore Mining Plant in Nigeria 3TPH Barite Beneficiation Process Plant in MoroccoGold Washing PlantIodine Mining Processing Equipment Flow Chart