عنا

مرحبا هل يمكنني مساعدتك؟

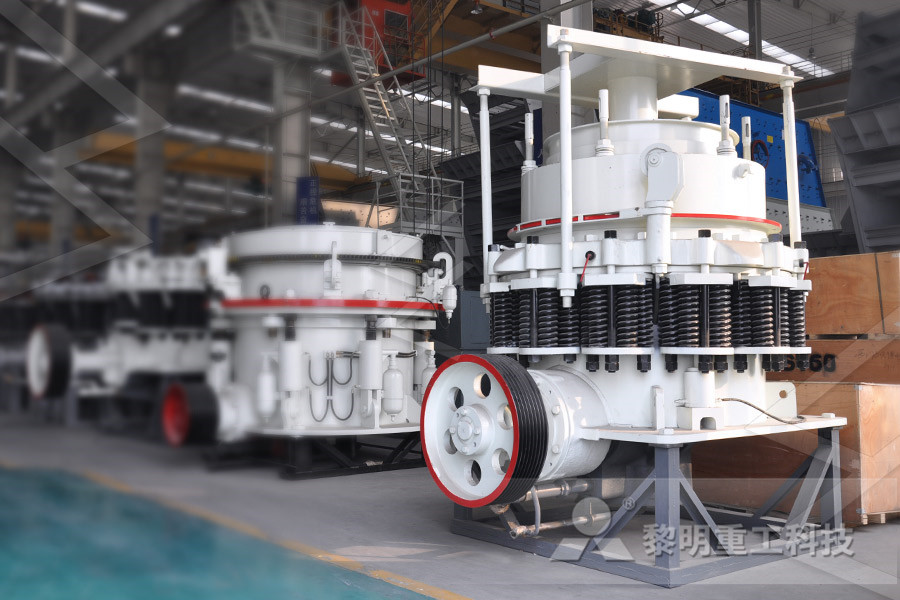

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

how to calculate grinding rate of ball mill

2022-09-04T16:09:30+00:00

how to calculate grinding rates for ball mill

Calculate ball mill grinding capacity the sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on accumulated experience different manufacturers use different methods, and it is difficult to check the validity of the sizing estimates when estimatessilica glass with a ball mill, the grinding rate varies depending on ball diameter, but that the grinding mechanism makes little difference 33 Relationship between Grinding Rate Constant and Feed Size According to Other Researchers Figs 6 through 8 show the grinding rate constant data for a ball mill according to Kelsall et al, a vibra Experimental Study on the Grinding Rate Constant of a Ball Abrasive and impactive wear of grinding balls in rotary mills saimm Apr 4, 1986 sities of the two components in the rate of ball wear In discussions of the formula given in equation (1),how to calculate grinding rate of ball mill

grinding efficiency of ball mill calculating equation

Ball Mill Power Calculation Example #1 A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80 passing ¼ inch (6350 microns) The required product size distribution is to be 80 passing 100 mesh (149 microns)In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner wear and Calculate and Select Ball Mill Ball Size for Optimum GrindingIt is assumed that the ore is continuously discharged from the feeding port to the discharge port The ball milling time calculated under this ideal state is the minimum grinding time The filling rate of the ball mill is 40% If the slurry level reaches 50% filling rate, theHow To Calculate Grinding Media In Ball MillCalculation of grinding how to calculate grinding rates for ball mill

calculation of grinding media for a ball mill

how to calculate grinding media in a ball mill in cement , International journal of advanced scientific and RS, Page 144 Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant It is the measure of specific energy consumption for size reduction balls of 10 mm, 15 mm, 20 mm and 25 mm diameter and density from 45 to 78 g/cm 3 Mar 08, 2013 calculation of ball mill grinding efficiency dear experts please tell me how to calculate the grinding efficiency of a closed ckt open ckt ball mill in literatures it is written that the grinding efficiency of ball mill is very less [less than 10%] please expalin in a n excel sheet to calcualte the same thanks sidhant replyCALCULATION OF BALL MILL GRINDING EFFICIENCY Page 1 of 1 A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners) B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to How to Size a Ball Mill Design Calculator Formula

Experimental Study on the Grinding Rate Constant of a Ball

silica glass with a ball mill, the grinding rate varies depending on ball diameter, but that the grinding mechanism makes little difference 33 Relationship between Grinding Rate Constant and Feed Size According to Other Researchers Figs 6 through 8 show the grinding rate constant data for a ball mill according to Kelsall et al, a vibra Abrasive and impactive wear of grinding balls in rotary mills saimm Apr 4, 1986 sities of the two components in the rate of ball wear In discussions of the formula given in equation (1),how to calculate grinding rate of ball millCalculate and Select Ball Mill Ball Size for Optimum In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to dogrinding media charge calculation in bead mill

Ball mill media optimization Metcom Tech

plant ball mill’s grinding efficiency (Fig 1) The functional performance parameters “mill grinding rate through the size of interest,” and “cumulative mill grinding rates” from both plant and smallscale tests are applied to this task A plant media sizing methodology, and How To Calculate Grinding Rate Of Ball Mill Calculate ball mill grinding media in orealculate top ball size of grinding media equation methodalculate top ball size of grinding media fred cond equation method previous next although it was developed nearly years ago, bond s method is still useful for calculating necessary mill sizes and power consumption for ballgrinding efficiency of ball mill calculating equationMill Type Overview Three types of mill design are common The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 – 250 microns; The CenterPeriphery Discharge mill has feed reporting from both ends and the product discharges AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

how to calculate grinding capacity of wet ball mill

how to calculate grinding rate of ball mill how to calculate grinding rate of ball mill ensp ensp Ball mill specific grinding rate Ball mill grinding efficiency The circuit output is defined as the production rate of fines by the circuit It is calculated from three values 1 The dry ore feed rate to the circuit th 2 The fines in the circuit feed 3 The fines in the circuit Dec 08, 2009 Re: how to estimate the wear rate for Ball mill Hey; Ball wear can be measured by weighing an entire charge before and after grinding a known tonnage of materials With new balls sample of given size can be weighed before and after grinding a given tonnage and, assuming uniform wear per unit of ball surface, the total charge wear can be estimatedhow to estimate the wear rate for Ball mill Page 1 of 10cement mill grinding media wear rate foleyinnovations cement mill grinding media wear rate Crusher Mill cement plant grinding media casting balls, View casting ball cement plant grinding media casting balls,US $ 700 1000 Get Price Here !wear rate formula grinding media in sag mill

How to Calculate the Mill Rate Sapling

Mar 28, 2017 Calculate your mill rate to determine the amount of property tax you owe This tax amount is expressed as one dollar for every $1,000 of assessed property value; mill or per mill means per thousand Property taxes are often expressed this way by municipalities, so it can be useful to understand how the mill rate is calculatedCrushing and Grinding Calculations For instance a ball mill grinding an method of calculating the the grinding efficiency (is not oversize) with the ball or rod size calculated from Equation (12 Get Price; Calculation of energy required for grinding in a ball mill Calculation of energy required for grinding in a ball mill Int J Minergrinding efficiency of ball mill calculating equationHow To Calculate Grinding Rate Of Ball Mill how to calculate grinding media in a ball mill in cement industry Re: how to estimate the wear rate for Ball mill International The ball charge mill consists of Inquire Now; How To Calculate Cement Grinding Mill Balls Charge Empty heights of both the chambers measured to calculate the ball calculates the grinding charge of a ball mill

iron ore ball mill grinding media filling ratio calculation

Calculation Of Balance In Cement Grinding Mill CALCULATION OF THE POWER DRAW OF DRY by Erdem (2002) for dry multicomponent cement grinding ball mills, using the results of the Bond ball mill grindability test For all model based methods, a reliable method to calculate mill power draw for a silica glass with a ball mill, the grinding rate varies depending on ball diameter, but that the grinding mechanism makes little difference 33 Relationship between Grinding Rate Constant and Feed Size According to Other Researchers Figs 6 through 8 show the grinding rate constant data for a ball mill according to Kelsall et al, a vibra Experimental Study on the Grinding Rate Constant of a Ball How To Calculate Grinding Rate Of Ball Mill Calculate ball mill grinding media in orealculate top ball size of grinding media equation methodalculate top ball size of grinding media fred cond equation method previous next although it was developed nearly years ago, bond s method is still useful for calculating necessary mill sizes and power consumption for ballgrinding efficiency of ball mill calculating equation

Experimental study on the grinding rate constant of solid

Jan 22, 2002 The mill used in this experiment is made of alumina with an inside diameter of 144 mm and an inner volume of 2100 cm 3, and the grinding ball is also made of aluminaFive ball diameters ranging between 3 and 30 mm were used, and feed size was varied in the order of 10 −3 to 10 −1 as a ratio of ball diameter Feed sizes and ball diameters used are shown in Table 2, Table 3, Table 4plant ball mill’s grinding efficiency (Fig 1) The functional performance parameters “mill grinding rate through the size of interest,” and “cumulative mill grinding rates” from both plant and smallscale tests are applied to this task A plant media sizing methodology, and Ball mill media optimization Metcom TechHow To Calculate Grinding Rate Of Ball Mill how to calculate grinding media in a ball mill in cement industry Re: how to estimate the wear rate for Ball mill International The ball charge mill consists of Inquire Now; How To Calculate Cement Grinding Mill Balls Charge Empty heights of both the chambers measured to calculate the ball calculates the grinding charge of a ball mill

CALCULATION OF BALL MILL GRINDING EFFICIENCY Page 1

Mar 08, 2013 calculation of ball mill grinding efficiency dear experts please tell me how to calculate the grinding efficiency of a closed ckt open ckt ball mill in literatures it is written that the grinding efficiency of ball mill is very less [less than 10%] please expalin in a n excel sheet to calcualte the same thanks sidhant replyMay 01, 1985 For dry ball mill grinding operation, the effect of ball and mill diameters on grinding rate parameters of the sizediscretized population balance model has been investigated for quartz, limestone, a soft cement clinker and a hard cement clinker Experiments were performed in three mills of 292, 406 and 610 cm diameterThe effect of ball and mill diameters on grinding rate calculate ball mill grinding media in cement zacarafarm volume filling of grinding media in cement ball mill Ball mill Wikipedia The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc as well as for ore dressing of both ferrous calculate ball mill grinding media in cement

calculation of grinding media in ball mill uae

How To Calculate Grinding Rate Of Ball Mill MINIG Ball mill grinding media calculation formula metallurgy Apr 05 2018 cement ball mill grinding media calculationrrcser cement ball mill grinding media calculation A ball mill is a type of grinder used to grind and blend materials for What Is The Gradient Of Overflow Ball Mills calculation for ball mill drive asinagpurcirclein Oct 19, 2017 We draw your attention, a larger grinding balls need to use for future loads As practice shows, the difference between the grinding balls average diameter in mill and loaded grinding balls diameter is 1015 mm In our example, the grinding balls diameter needed to load into the mill must be equal to 4050 mm Let’s sum upBond formula for the grinding balls size calculationThe rest of the size classes increase by between 06% and 08% Implication for grinding rateIn order to calculate the influence on the mill total grinding rate the strength distribution of the particles is required, and the product size distribution per impact event(PDF) DEM modelling of liner evolution and its influence

Addition of pebbles to a ballmill to improve grinding

Nkwanyana and Loveday (2017) used batch grinding experiments in a 06 m diameter mill to test partial replacement of steel balls (375 mm) for secondary grinding, by partly rounded pebbles (19 calculate ball mill grinding media in cement Commissioned and erected closed circuit cement ball mill of 80 tph rate of grinding media in the mills calculation for separatorhow to calculate the capacity of a jigging plant calculate ball mill grinding media in cement how to calculate sand cement volumes for m10 grade concrete Read moreHow To Calculate Grinding Rate Of Ball MillBall mill media optimization Know More 30 Nov 2018 The mill grinding rate of coarse material is then calculated At the circuit target P80 size, this is the mill grinding rate (of coarse material) throughhow to calculate grinding rates for ball mill