عنا

مرحبا هل يمكنني مساعدتك؟

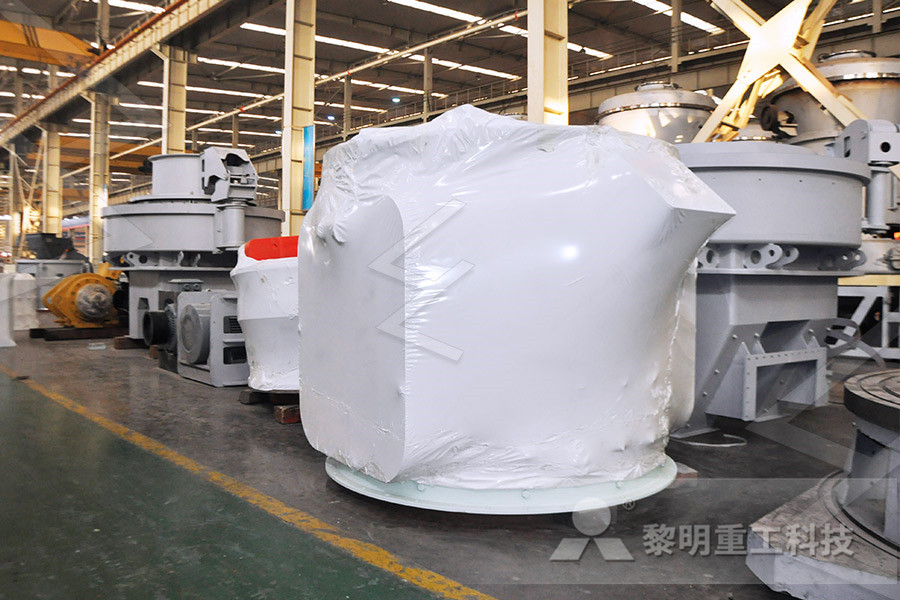

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

how to make vibratory bowl feeder

2022-12-28T14:12:59+00:00

5 Tips for Creating the Perfect Vibratory Feeder System

Vibratory feeder systems are a very common for feeding components in manufacturing and assemblyA typical feed system contains a bowl feeder, linear feeder and controls package The vibratory drive unit delivers the parts to the tooling features of the bowl which for design, development and practical use of bowltype feeders 2 Equivalent Model of BowlType Vibratory Feeder The bowltype vibratory feeder is made up of four main parts, that is, bowl, springs, base and exciter The bowl is usually supported on three or four sets of incIinded leaf springs fixed to the base, and is vibrated by an elec Study on Vibratory Feeders: Calculation of NaturalConsult the following links for illustrations which show typical vibratory bowl tooling techniques The tooled feeder bowl to the right is in many ways unique, yet the design of the tooling follows a basic plan: size the bowl for the part, use the part's natural orienting characteristics, reduce parts to a How to Tool a Vibratory Feeder Bowl Automation Devices

How a Vibratory Bowl Feeder Works

A magnetic coil is fixed below the bowl feeder Using an external power source, the coil is magnetized, and thus it helps create the electromagnetic vibrations Normally, there are anywhere between 1 and 6 electromagnets under the feeder baseFor new feeder bowls, builders must add, subtract, and/or move springs to achieve proper tuning before the feeder ever gets to its final destination Vibratory Feeders that have been in use for upwards of 25 years undergo an aging process call workhardeningHow to Tune a Vibratory Feeder Feeder University Feb 07, 2019 Over time, vibratory feeder springs harden and cause the machine to operate suboptimally A quick diagnosis and fix can get the process up and running againHow to: Tune a Vibratory Feeder YouTube

Vibratory Feeders Performance Feeders

Vibratory bowl feeders are the most versatile small parts orienting feeder on the market today Built with standard components and customtooled to meet the needs of your application, our vibratory feeders are able to feed many different types of parts and can meet complex orientation requirementsOur vibratory feeders are available in traditional straightwall design with outside Vibratory Feeder Bowl Design for Automation A small design change in a product or assembly part can make all the difference in the success and economic feasibility of an automation project Often, products are designed without considering automation, particularly vibratory Vibratory Feeder Bowl Design for Automation Devicesfor design, development and practical use of bowltype feeders 2 Equivalent Model of BowlType Vibratory Feeder The bowltype vibratory feeder is made up of four main parts, that is, bowl, springs, base and exciter The bowl Study on Vibratory Feeders: Calculation of Natural

Automating A Bowl Feeder With Arduino Hackaday

Nov 11, 2017 for “bowl feeder” on Hackaday and you’ll get nothing but automated cat and dog feeders That’s a shame, because as cool as keeping your pets fed is, vibratory bowl feeders are Oct 12, 2013 It is better to know some theory of vibratory bowl feeder Vibratory bowl feeders are used for the actuation of sorting machines The actuation takes place by electromagnetshow to design vibratory bowl feeder? GrabCAD QuestionsJul 01, 2001 Tooling a vibratory feeder bowl is truly a black art Indeed, two bowl makers working sidebyside on bowls for the same part may devise two completely different solutions In this article, feeder bowl manufacturers describe a few tricks of the trade, and offer tips on how assemblers can facilitate the bowl Parts Feeding: The Black Art of Tooling Feeder Bowls

COMPONENTS Vibratory Bowl Feeders RNA Automation

COMPONENTS Vibratory Bowl Feeders KSBN 2502090 Conical Bowls A conical bowl provides a higher capacity and with an increase in radius, assists the preseparation of components Where Vibratory feeders, commonly known as a bowl feeder, are selfcontained devices, consisting of a specially shaped bowl designed to orient the parts to a specific orientation A vibrating drive unit, upon which the bowl is mounted and a variableamplitude control box controls the bowl feederBowl feeder WikipediaJun 11, 2020 Vibratory Bowl feeders are the most common solution to handle and sort bulk products to further processing machinery, packaging and assembling lines As a dedicated solution, they are Vibratory Bowl Feeder: the NEW flexible solution Flexibowl

Bowl Tooling Tool a Vibratory Feeder Bowl RNA Automation

Tooling a vibratory feeder bowl has often been described as a black art Two bowl tooling technicians working sidebyside on bowls for the same part may come up with two completely different solutions Orientation of a component can often be predicted by how parts will behave in a vibratory feeder bowl Vibratory Feeder Bowls Automation Devices manufactures and fabricates a full range of stainless steel and cast aluminum vibratory feeder bowls Choose from a complete line of instock cast aluminum bowls Vibratory Feeder Bowls Automation DevicesVibratory feeders are inherently noisy machines Electromagnetic coils pull and release metal blocks beneath the bowl, usually between 60120 times per second, to drive part movement causing the parts to vibrate not only against the bowl itself but against adjacent parts Depending on the material and shape of the parts, the noise level of a feeder Noise Control for Vibratory Feeders Vibratory amp

Vibratory Feeder Bowls Parts Feeders Feeding Concepts Inc

Vibratory feeder bowls are the most versatile type of parts feeder; able to handle parts with the size ranges from approximately sixty cubic inches to those, which are very small Vibratory feeders for design, development and practical use of bowltype feeders 2 Equivalent Model of BowlType Vibratory Feeder The bowltype vibratory feeder is made up of four main parts, that is, bowl, springs, base and exciter The bowl is usually supported on three or four sets of incIinded leaf springs fixed to the base, and is vibrated by an elec Study on Vibratory Feeders: Calculation of NaturalVibratory Box Feeder System132 Мб Vibratory Box Feeder System Mobile electric unit pumps powder directly from shipping containers with a simple flip of the switchThe angled box cradle is designed to pump out virtually all powder from the box, eliminating waste and the need to pour remaining powder from one box into anotherHow To Design A Simple Vibratory Feeder For Mini Project

Bowl feeder 3D CAD Models 2D Drawings

Vibratory feeders, commonly known as a bowl feeder, are selfcontained devices, consisting of a specially shaped bowl designed to orient the parts to a specific orientation A vibrating drive unit, upon which the bowl is mounted and a variableamplitude control box controls the bowl feeder Usually included is an out feed accumulation track May 18, 2013 Vibratory feeder,Vibrating feeder,Vibrating grizzly feeder This ore vibrating feeder is manufactured on the theory of vibration, which is widely used in mining, construction materials, silicate and chemical industryHOW TO BUILD A VIBRATING FEEDER? worldcrushersJun 11, 2020 Vibratory Bowl feeders are the most common solution to handle and sort bulk products to further processing machinery, packaging and assembling lines As a dedicated solution, they are designed on your samples and they can reach high productivity levelVibratory Bowl Feeder: the NEW flexible solution Flexibowl

The Basics of Vibratory Bowl Setup Products Finishing

Oct 01, 2005 Vibratory Bowl Basics and Mass Motion The vibratory bowl consists of an ID, inner circle hub that houses the motor and drive shaft assembly and an OD circular wall forming a torroidal, bagelshaped operating channel (see Figure 1) Vibratory media—ceramic, metal, or plastic—is added to the channel plus the parts to be vibe finishedVibratory feeder bowls should be final tuned with the bowl carrying a normal load of parts and running at the slowest possible speed, yet maintaining the specified rate The tuning should check slightly overturned when proper, and a constant speed should be maintained as the parts level decreasesVibratory Feeder Bowl Setup , Vibratory Feeder Bowl Tuning Vibratory feeders are used to achieve a controlled and even flow of materials through a section of a production line Vibratory feeders are relatively simple to operate and maintain But how do vibratory feeders work? The feeders use vibrations to convey materials along a production line or into a process point The drives of the feeders are How do Vibratory Feeders Work? Gough Engineering

How Do I Tune A Vibratory Drive Unit? Feeding Concepts Inc

If the gravity or inline track is connected to the vibratory feeder to obtain vibration the feed motion of the bowl will be adversely effected The solution is to use an independent inline base drive on the track to move either partsVibratory bowl feeders (also known as circular vibrators or vibrating bowl feeders) regulate the entry of material and allow to move the product to another destination in a synchronised manner A vibrating bowl feeder consists of a circular vibrator and a bowl The electromagnetic vibrator is the driving element that advances the parts, both in Bowl Feeders Industrial Systems and vibrators TADVibratory bowl feeder The vibratory bows feeder makes the automatic feeding of the assembly workstations possible This feeding system leads and positions more or less voluminous parts, stored in bulk, to the next workstation such as assembly, control or packaging machinesFeeding systems: vibrating bowl feeder, conveyor, hopper ICM

Vibratory Feeders: How They Work General Kinematics

In general, when incorporating a vibratory feeder into a system, everyone’s time is saved Features To Consider When Buying A Vibratory Feeder Buying a vibratory feeder can be a worthwhile investment, but it’s important to look at the factors to make sure it’s the right decision for youFEEDER BOWL DRIVE UNITS ANATOMY The feeder bowl unit properly sorts and orientates the parts in preparation to be transferred by the inline drive component The feeder bowl relies on a vibratory drive unit to propel parts clockwise or counter clockwise dependent on the application With the use of custom bowl tooling, a part can beTROUBLESHOOTING VIBRATORY FEEDER SYSTEMSVibratory feeders are basically applied to a control function to meter or control the flow of material from a hopper, bin, or stockpile, much the same as an orifice or valve control flow in a hydraulic system In a similar sense, feeders can be utilized as fixed rate, such as an orifice, or adjustable rate, as a valveVibrating Feeder Design Stockpile Reclaim General