عنا

مرحبا هل يمكنني مساعدتك؟

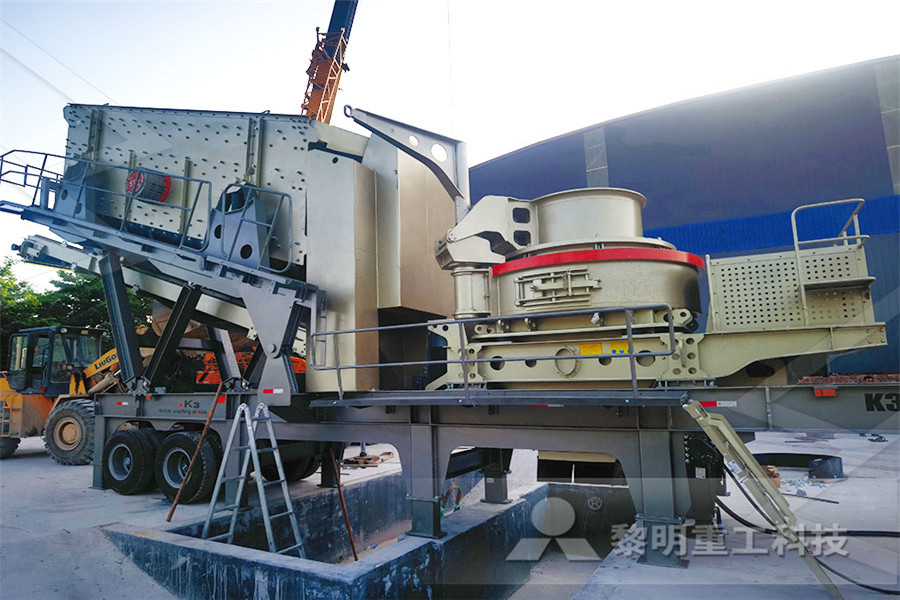

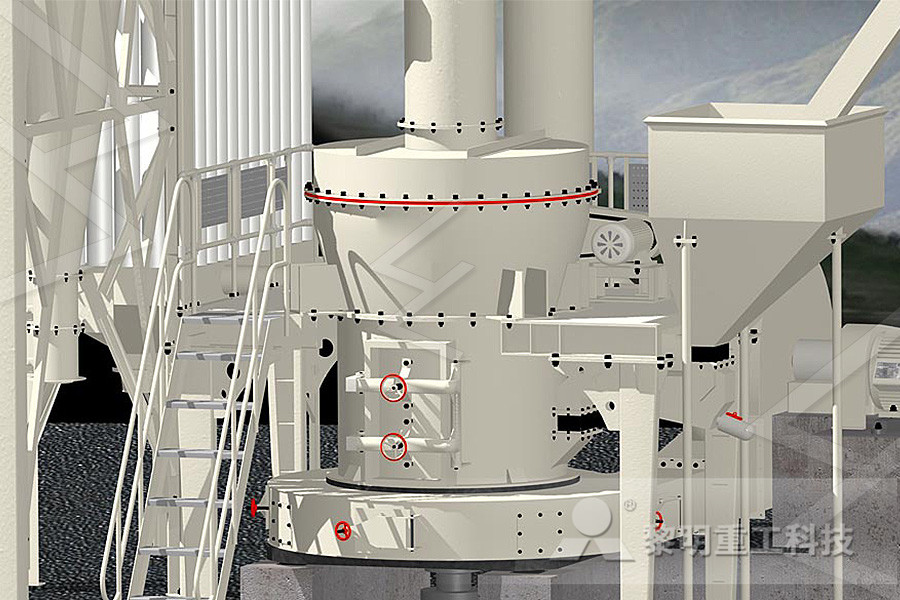

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

ball mill safe procedure

2019-10-17T23:10:39+00:00

(DOC) BALL MILL STANDARD OPERATING PROCEDURE: SL NO

BALL MILL STANDARD OPERATING PROCEDURE: SL PROCEDURES STATUS REMARK NO 1 Ensure that all the items mentioned in the prerequisites are available 2 Connect the power supply (3 Phase) [415 V, 50/ 60 HZ] AC with Earthing (use 5 core cable to draw earthing from the input supply) 3Operating Procedure for Ball miller Note: Internal Timer has been modified to time for 9,999 minutes –Extended time This ball mill was designed to run 15 minutes, Average Time The original total time was 999 minutes maximum Now it is 9,999 minutes Ie, 160 hours To operate longer times, two Cooling Fans have been installed and anOperating Procedure for Ball millerBall Mill and Grinding Circuit Preparation for StartUP The following items must be checked before the equipment in the Grinding Circuit is started Check the ore slot feeder for obstruction or hang—ups Check the ball mill belt feeder for undue buildup of material Check oil level in ball mill lube oil tanks Also, check grease level in the mill ring gear spray lube drum Ensure that the Ball Mill Operation Grinding Circuit Startup Shutdown

Ball Mill Maintenance Installation Procedure

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available As such you will find it is designed and constructed according to heavy duty specifications It is designed along sound engineering principles In terms of safety the electrical lockout of the machinery is the single most important step in this procedure After the power disconnected, the circuit is tested Puts personal locks on the tongs of power This is to ensure that mill cannot be reenergized until the maintenance is completeAMIT 129: Lesson 12 Crusher and Mill Operation Safety It is designed to be used as an adjunct to teaching Safety Procedures and to act as a reminder to users prior to machine use Date of last review Signature Title: Safety Operating Procedures Milling Machine Author: David Large Last modified by: Boldt, John Created Date: 3/19/2013 6:30:00 PMSafety Operating Procedures Milling Machine

procedure to replace shell liners of a ball mill

Safe and simple: Ball mills Conventional design Every year around 14 Mill shell lining quick replacement of plates, ed to have CPB staff to are inconsistent, Compact Depending on to 26 % chrome are used casting procedureball mill safe operation and maintenance Ball mill has features of high operation rate, grinding effect, and we must follow close to the line of the operation procedures and maintenance procedures of ball mill Before the start ball mill, you should check whether the connection bolts are tightened, and tightening condition of the spoon head of the ore feeder, and key of gears, couplings and ball mill safe operation and maintenanceOperating Procedure for Ball miller Note: Internal Timer has been modified to time for 9,999 minutes –Extended time This ball mill was designed to run 15 minutes, Average Time The original total time was 999 minutes maximum Now it is 9,999 minutes Ie, 160 hours To operate longer times, two Cooling Fans have been installed and anOperating Procedure for Ball miller

Safety Hazards Concerning Ball Mill Experiment

Recommended Hazards Wet Ball Mill Safety safety procedure using wet ball mill machine Standard Operating Procedure Standard PolisherGrinder The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 115 times the shell diameter Figure 811The feed can be dry withsafe operating procedures for ball mill safe operating procedures for ball mill manufacturer in Shanghai China safe operating procedures for ball mill is manufactured from Shanghai It is the main mineral processing solutions TON stone crushing machine projectsafe operating procedures for ball principles of ball mill in coal cleaning and safety rules Dec 30, 2018 1 Open one side of vessel by opening the screw situated over the both sides of the vessel and remove the cap from 2 Pour the ingredients desired no and size of balls into the vessel 3 Close the mouth of the vessel by placing its cap and tightening the screws on it 4 Insert the main plug SOPBall Mill Gpatindia: Pharmacy Jobs, Admissions

Safety Operating Procedures Milling Machine

It is designed to be used as an adjunct to teaching Safety Procedures and to act as a reminder to users prior to machine use Date of last review Signature Title: Safety Operating Procedures Milling Machine Author: David Large Last modified by: Boldt, John Created Date: 3/19/2013 6:30:00 PMA ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating about its axis TBall mill Wikipedia1 The first item of procedure to operate the milling machine is A secure work piece B set cutting speed C turn on power D obtain teacher permission 3 Make measurements or setups only when A you have permission B you have read and understand safety rules C the machine is at a dead stop D All of the above 4SAFETY RULES BASICS FOR MILLING MACHINES

Safety Specifications for Mills and Calenders in the

This standard covers the safety guarding of mills and calenders in the rubber industry at the point of operation Such items of installation and maintenance as are necessary for safe operation are also included 12 Purpose This standard is intended to provide for the safety Sep 11, 2020 Safety of Rebel/Thumblers tumbler ball mill posted in Safety: Hello, I am wondering what other Pyros think about the safety of the Rebel 17 pound ball mill It seems like it would be a deadly explosion if something were to go wrong while handling the drum before emptying it out, since it is sealed with 6 threaded posts and nuts I know it is a must to wear PPE while emptying the mill but I Safety of Rebel/Thumblers tumbler ball mill Safety APC Ball Mill Operating Procedure Duocarpediem Operating procedure for ball miller note internal timer has been modified to time for 9999 minutes extended time this ball mill was designed to run 15 minutes average time the original total time was 999 minutes maximum now it is 9999 minutes ie 160 hours to operate longer times two cooling fans have been installed and anBall Mill Relining Standard Operating Procedure

Ball Mill Safety : Mine Safety and Health Administration

Jul 02, 2008 Ball Mill Safety DVD573 1998 Developed cooperatively by MSHA and Lehigh Portland Cement Company Outlines the various steps – precautions and procedures – that must be taken to safely and efficiently shut down a ball mill, enter, inspect, service (repair or perform routine maintenance), and restart the operationIn terms of safety the electrical lockout of the machinery is the single most important step in this procedure After the power disconnected, the circuit is tested Puts personal locks on the tongs of power This is to ensure that mill cannot be reenergized until the maintenance is completeAMIT 129: Lesson 12 Crusher and Mill Operation Safety 3) Mill start up, Balancing and Heating Phase A Step by step discussion of how to properly start up and mill 1Use of low speed 2Correct procedure to close rear nip and the addition of product to be milled 3Correct procedure to balance the mill 4When to bring on cooling water and discussion of water cooling system BThree Roll Mills Safety keithmachinery

Operating Procedure for Ball miller

Operating Procedure for Ball miller Note: Internal Timer has been modified to time for 9,999 minutes –Extended time This ball mill was designed to run 15 minutes, Average Time The original total time was 999 minutes maximum Now it is 9,999 minutes Ie, 160 hours To operate longer times, two Cooling Fans have been installed and anA ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating about its axis TBall mill WikipediaThis standard covers the safety guarding of mills and calenders in the rubber industry at the point of operation Such items of installation and maintenance as are necessary for safe operation are also included 12 Purpose This standard is intended to provide for the safety Safety Specifications for Mills and Calenders in the

1910216 Mills and calenders in the rubber and plastics

Mills Where a mill is so installed that persons cannot normally reach through, over, under, or around to come in contact with the roll bite or be caught between a roll and an adjacent object, then, provided such elements are made a fixed part of a mill, safety control devices listed in ball mill relining standard operating procedure pdf free Ball mill operating procedure safe operating procedure is the area around the ball mill free of sliptrip standard operating procedure of ball mill the westbrook historical society the photo on the left is from a news article which reported on the dedication of an elm tree and bronze marker in riverbank park ball mill relining standard standard operating procedure for ball millsafe operating procedures for ball mill – Crusher Machine Customers want and that is our goal we produce ore crusher safe operating procedures for ball mill mill crusher mobile crushing plant processing equipment according to the specific needs of our design and production lines fully the interests of customersball mill design and operation procedure mobile crusher

Introduction to rubber processing and safety issues

Safe reach distances should meet the requirements of Table 4 of BS EN ISO 13857: Safety of machinery Safety distances to prevent hazard zones being reached by upper and lower limbs The floating weight trap with the fixed bridge casting from either the feed opening or the rear inspection doorof the procedure: grindout, mill stoppage, mill startup and the transition period to steady state Stresses, generated in the ball charge, increase, which may result in spalling of balls and blocking the grate discharge Optimization of mill performance by using online ball and pulp measurements by B Clermont* and B de Haas* SynopsisOptimization of mill performance by usingBall mills stop procedure pdf ball mill grinding circuit the ball mill is in closed circuit with a sump and three cyclone classifiers the ore and trim water are added get price grinding in ball mills modeling and process control keywords ball mills grinding circuit process control i introduction grinding in ball mills is an Safe Operating Ball Mills Stop Procedure Ball Mill Cafe Grell

Procedure For Replacement Of Ball Mill Shell Liner Plates

Composite Steel Claded Mill Liner COMPOSITE STEEL CLADED MILL LINER lifter bar shell plates as liners to carry the ball charge orerocks inside up to a point known as the charge should or where the centrifugal forces acting on the charge components get equal to the wt of the charge components replacement of inner lining of the mill is a cumbersome procedure and theMill operating proceduresHenan Bailing Machinery Co,Ltd some of the normal operating procedures Ball, Now I will tell you thatThese are the correct ball mill operating rules, but we also know how to repair ball mill method, the first time in the ball mill was immediately replaced broken bad wearing parts, so as not to delay the normal operation of ball millsoperating procedures ball mill Dec 30, 2018 BALL MILL STANDARD OPERATING PROCEDURE 1 Open one side of vessel by opening the screw situated over the both sides of the vessel and remove the cap from vessel 2 Pour the ingredients desired no and size of balls into the vessel 3 Close the mouth of the vessel by placing its cap and tightening the screws on it 4 Insert the main plug into the main switchSOPBall Mill Gpatindia: Pharmacy Jobs, Admissions

principles of ball mill in coal cleaning and safety rules

safe operating procedures for ball mill safe operating procedures for ball mill manufacturer in Shanghai China safe operating procedures for ball mill is manufactured from Shanghai It is the main mineral processing solutions TON stone crushing machine projectsafe operating procedures for ball Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mills an overview ScienceDirect Topics