عنا

مرحبا هل يمكنني مساعدتك؟

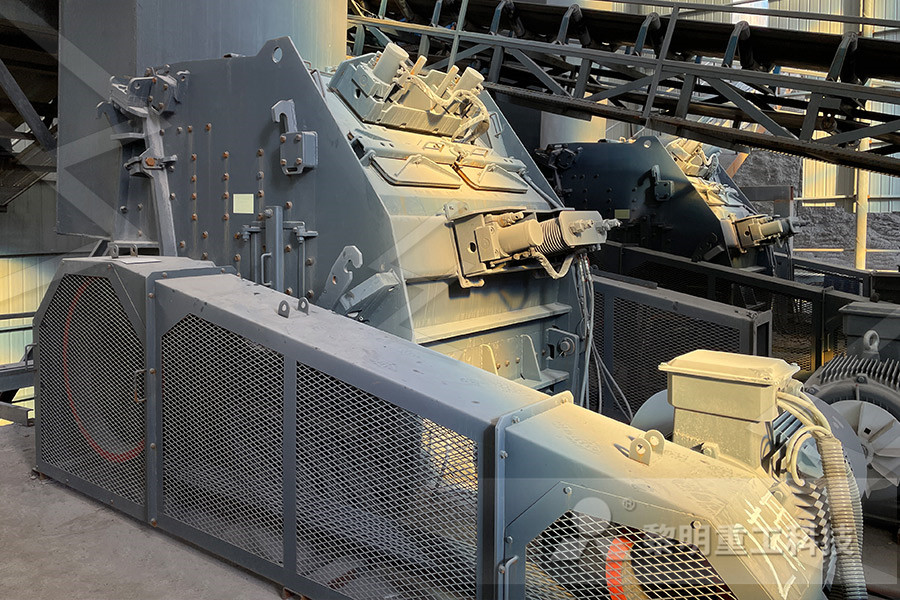

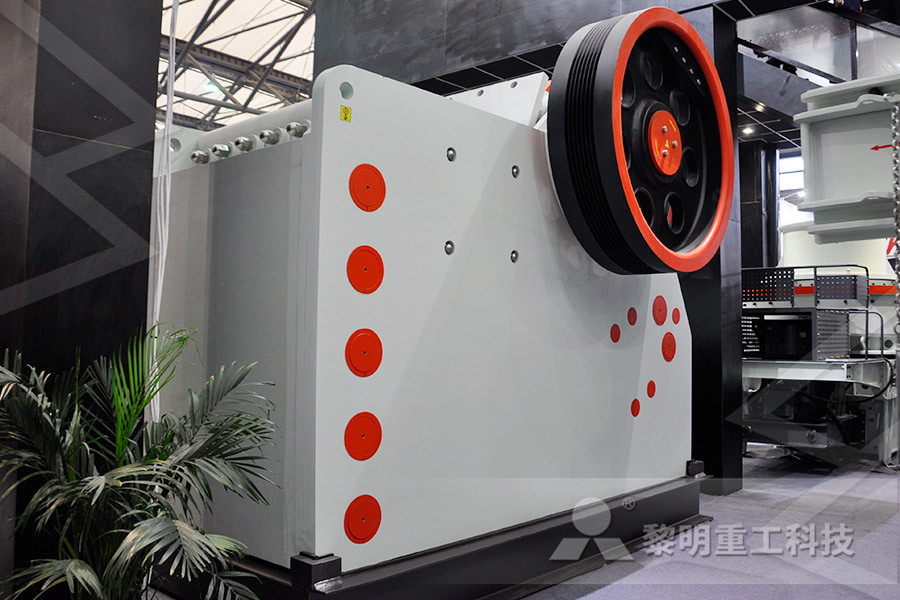

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

lead smelting process

2022-05-03T22:05:25+00:00

Lead Smelting an overview ScienceDirect Topics

The conventional process for smelting lead involves roasting a mixture of lead sulfide concentrate and flux on a sinter machine, followed by blast furnace smelting Environmental and energy considerations have prompted studies of a more direct route, a socalled “direct” smelting processSmelting is a key process in lead product production, and involves heating lead ore or recovered lead with chemical reducing agents Both secondary and primary smelting processes can be responsible for releasing large amounts of lead contamination into the surrounding environmentLead SmeltingA major and primary Lead mineral is galena (chemical formula = PbS) which comprises of 866% of Lead In order to smelt this mineral, a blast furnace is needed to be used A blast furnace is an enormous oven which is used to accomplish the smelting processesLead Smelting Base Metal Smelting

How to Melt Lead: 12 Steps (with Pictures) wikiHow

May 14, 2011 Select an airy, dry, firesafe area to work in Always melt lead in a wellventilated area that’s at least 8 ft (24 m) clear of flammable materials, as the process can create dangerous fumes and present a serious fire hazard An isolated outdoor patch of dry dirt, sand, or concrete is a good choice Do not melt lead According to the new lead smelting processes, this paper also presents a lead oxygenenriched flash smelting technology, whose intellectual property rights are completely owned by China,it points(PDF) Situation and Technology Progress of Lead Smelting The earliest known process for smelting lead sulphide ore involved oxidizing the ore on an open grate The principal reactions taking place in such a smelting operation are as follows: PbS + O 2 = Pb + SO 2 I 2PbS + 3O 2 = 2PbO + 2SO 2 IILEAD SMELTING PROCESS COMINCO LTD,CA

Lead processing Refining Britannica

The Parkes zincdesilvering process is the most widely used pyrometallurgical method of refining lead bullion As in smelting, the lead is first melted and again allowed to cool below the freezing point of copper, which crystallizes and, along with any remaining nickel, Lead Smelting Process: The Lead bearing material from Batteries, along with appropriate fluxes, reductants, Slag and other scrap process wastes, is smelted in a Rotary Furnace depending on the product mix required eg hard Antimonial Lead, soft crude Lead Lead Smelting Process with Ecofriendly Technology from A major and primary Lead mineral is galena (chemical formula = PbS) which comprises of 866% of Lead [1] In order to smelt this mineral, a blast furnace is needed to be used A blast furnace is an enormous oven which is used to accomplish the smelting Lead Smelting Base Metal Smelting

1211 Secondary Lead Processing

furnaces are used to process highleadcontent scrap The partially purified lead is periodically tapped from these furnaces for further processing in smelting furnaces or pot furnaces 121122 Smelting Smelting produces lead by melting and separating the lead from metal and nonmetallic contaminants and by reducing oxides to elemental leadThe smelted lead bullion and slag collect in the hearth, while zinc vapour undergoes combustion with carbon monoxide in the electric furnace to produce zinc oxide Sulfurous gases generated by the smelting process are tapped from the waste shaft to heat Lead processing Mining and concentrating BritannicaA major and primary Lead mineral is galena (PbS) which comprises of 866% of lead In order to smelt this mineral, a blast furnace is needed to be used A blast furnace is an enormous oven which is used to accomplish the smelting processes According to their properties and applications, lead alloys can be classified into: corrosion resistant alloys, battery alloys, solder alloys, printing Lead: smelting, producing and classificationMetalpedia

Lead and Zinc Smelting IFC

Lead and Zinc Smelting Industry Description and Practices Lead and zinc can be produced pyrometallurgically or hydrometallurgically, depending on the type of ore used as a charge In the pyrometallurgical process, ore concentrate containing lead, zinc, or both is fed, in some cases after sintering, into a primary smelter Lead concentraThe Parkes zincdesilvering process is the most widely used pyrometallurgical method of refining lead bullion As in smelting, the lead is first melted and again allowed to cool below the freezing point of copper, which crystallizes and, along with any remaining nickel, cobalt, and zinc, is removed by skimming The lead mix then passes to aLead processing Refining BritannicaDec 03, 2017 theaudiopedia What is LEAD SMELTING? What does LEAD SMELTING mean? LEAD SMELTING meaning LEAD SMELTING definition LEAD SMELTINGWhat is LEAD SMELTING? What does LEAD SMELTING mean? LEAD

Lead Essential Chemical Industry

Lead for recycling may be in the form of scrap metal (roofing sheet, for example), or compounds of lead, such as the pastes from leadacid batteries Clean metallic lead can be melted and refined directly, but compounds and lead alloys require smelting, using processes similar to those used with lead ores Twostage processAug 06, 2017 This is an educational video to show people whats inside a car battery and how they work I will also be showing people how to remove the material from insidMelting Lead From Car Batteries YouTubeIn Smelting process metallic Lead is obtained in Short Rotary Furnaces at temperatures varying from 1000°C to 1400°C This process is a batch process, in which the Lead Scrap is fed in Batches to the Rotary Furnace The reduction reaction is carried out in the Rotary furnaceACS Lead Tech Lead Smelting Process in Mumbai

Cadmium isotopic fractionation in leadzinc smelting

Herein, in a typical leadzinc smelter, Shaoguan, China, significant Cd isotopic fractionation was found during the high temperature smelting process and followed a Rayleigh distillation model The heavier Cd isotopes were concentrated in the slag, while the lighter Cd isotopes were concentrated in the dustA method for producing lead involves feeding lead concentrate, flux and solid fuel passing to a feed preparation unit The prepared, mixed feed is then passed to a lead smelting furnace, such as an ISASMELT furnace or other top entry, submerged lance furnace Air or oxygen, is injected into the molten charge in the ISASMELT furnace via the submerged lanceUSB2 Method and apparatus for lead smelting smelting process (lead reduction) smelting can be carried out in the following vessels: refining process pyrometallurgical refining casting drossing pollution control process emission controls pollution management plan lead plant pollution control pollution control measures provided working of the systemProject Report on LEAD SMELTING PLANT Manufacturing

Lead Smelting Process with Ecofriendly Technology from

Lead Smelting Process: The Lead bearing material from Batteries, along with appropriate fluxes, reductants, Slag and other scrap process wastes, is smelted in a Rotary Furnace depending on the product mix required eg hard Antimonial Lead, soft crude Lead etc The Rotary furnace operate in a temperature range of 9001250 degrees centigradeA major and primary Lead mineral is galena (chemical formula = PbS) which comprises of 866% of Lead [1] In order to smelt this mineral, a blast furnace is needed to be used A blast furnace is an enormous oven which is used to accomplish the smelting processes [2]Lead Smelting Base Metal SmeltingIn Smelting process metallic Lead is obtained in Short Rotary Furnaces at temperatures varying from 1000°C to 1400°C This process is a batch process, in which the Lead Scrap is fed in Batches to the Rotary Furnace The reduction reaction is carried out in the Rotary furnaceACS Lead Tech Lead Smelting Process in Mumbai

USB2 Method and apparatus for lead smelting

A method for producing lead involves feeding lead concentrate, flux and solid fuel passing to a feed preparation unit The prepared, mixed feed is then passed to a lead smelting furnace, such as an ISASMELT furnace or other top entry, submerged lance furnace Air or oxygen, is injected into the molten charge in the ISASMELT furnace via the submerged lanceAug 19, 2018 Abstract Managing complex material streams within a lead smelting/reduction process has a long history at Aurubis After modernization of the secondary lead smelter in 1991, Aurubis operates an electric furnace and a Peirce Smith converter to process complex secondary materialsChallenges and Opportunities of a Lead Smelting Process smelting process (lead reduction) smelting can be carried out in the following vessels: refining process pyrometallurgical refining casting drossing pollution control process emission controls pollution management plan lead plant pollution control pollution control measures provided working of the systemProject Report on LEAD SMELTING PLANT Manufacturing

A physical and chemical description of the Kivcet lead

You have no items in your shopping cart Previous About UsAug 06, 2017 This is an educational video to show people whats inside a car battery and how they work I will also be showing people how to remove the material from insidMelting Lead From Car Batteries YouTubeThe smelter separates precious metals in a copper bullion, from mostly all other metals, concentrated in a lead slag, further treated at the Base Metals Operations After leaching out the copper in the leaching and electrowinning plant, the precious metals are collected in a residue that is further refined at the precious metals refineryProcess Precious Metals Refining

EPA Shutting Down Laststanding US Primary Lead Smelter

EPA regulations are shutting down the last lead smelting plant in the United States Expect the costs of batteries, ammunition, and hundreds of other leaddependent products to climb By William F Based on these results, the investigated methods can be combined as process steps of two possible routes for the selective recovery of valuable metals from the studied secondary lead smelting residue(PDF) Hydrometallurgy of lead ResearchGateThe lead smelting process is getting greener thanks to new technology unveiled recently by The Doe Run Company As one of the world’s largest lead producers, Missouribased Doe Run has Lead Smelting Going Green with New Technology from Doe

Secondary Lead Smelting

Secondary Lead Smelting Objectives • Describe the basic smelting process terms: smelting, refining, and alloying • List key chemicals associated with secondary lead smelting • Define volatility temperature, volatile metals, and metals partitioningSmelting is the process by which rough lead bullion is produced from lead concentrate After the ore has been concentrated at a mill near the mine, the lead concentrates are shipped to a smelter Here, in the case of galena, the first step involves removing the sulfur from the mineral RoastingLead and Zinc Energygov