عنا

مرحبا هل يمكنني مساعدتك؟

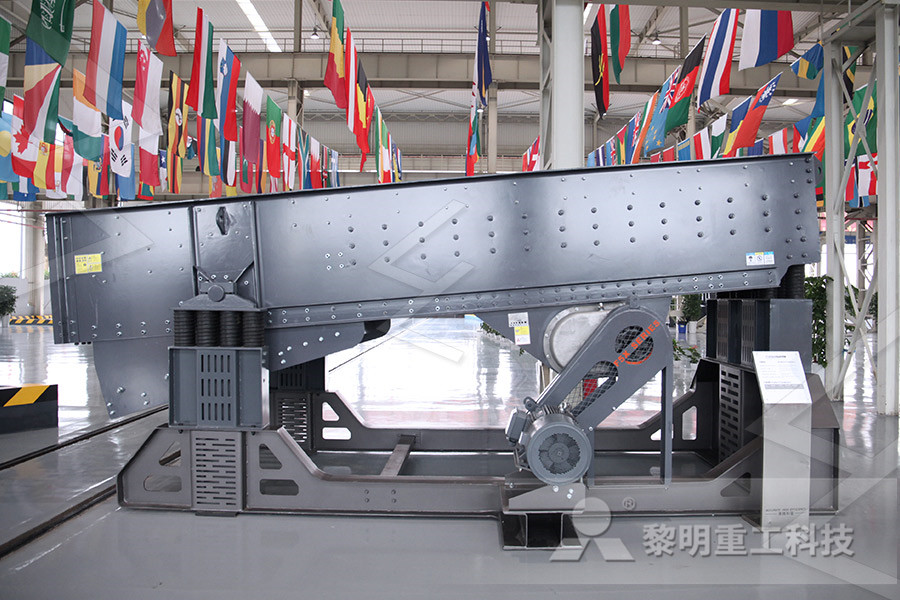

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

milling vertical spindel

2023-03-01T13:03:55+00:00

What's the Difference Between Vertical and Horizontal

In vertical mills, the spindle axis is vertically oriented Milling cutters are held in the spindle and rotate on its axis Typically the spindle can be extended or the table raised or lowered to produce the same effect, allowing for plunge cuts and drilling The two kinds of vertical mills are bed mills and turret millsFeb 08, 2021 Milling is a machining process in which a work piece is moved relative to a rotating tool with cutting edges in order to remove material As the milling spindle rotates the cutting tool, the work is fed into it from various directions to form the desired shapeWhat Is a Milling Spindle? (with picture)Milling Spindles Setco is the premier manufacturer of standard and custom milling / drilling spindles for Machining Centers Types of spindles include: beltdriven, directdrive, geared and motorized All spindles are available in cartridge or foot mounted block housingsMilling Spindles Turning Spindles Grinding Spindles

Milling Machine Spindle [Complete DIY Guide

Milling Machine Spindle [Complete DIY Guide] [ Milling Machine Parts Home] The spindle is the heart of any mill It consists of a rotating assembly with a taper where tool holders may be installed A spindle motor with optional transmission of some kind rotates the spindleThe milling head is the upper part of a vertical mill machine It consists of spindle, driving motor and other controlling mechanismsMilling machine parts and their functions studentlessonThe third axis is provided by a vertical spindle (Zaxis) that moves up and down The mill can be used for milling slots, holes or pockets, drilling, profiling, boring and surfacing Most milling is done using “end mills” that look much like a drill bit except they are capable of cutting on the sides as well as on the endMilling Machine Terminology – Sherline Products

Introduction to Machining: Milling Machine

vertical spindle machine with a swiveling head Although there are several other types of milling machines, shown is the vertical milling machine • A milling machine removes metal by rotating a multitoothed cutter that is fed into the moving workpiece The spindle can be fed up and down with a quill feed lever on the headThe 860C converts in less than 5 minutes from horizontal to vertical (or vice versa) and simultaneously does vertical and horizontal milling The heavyduty horizontal Features allgear positive drive, with highinertia Flywheel, 3 hp variable speed drive with direct lever control, and #40 MMT taper spindle equipped with draw barVertical Milling — WellsIndex Milling Machines1PCS Milling Shaft R8 B132 Spindle +Bearings Assembly Milling Shaft for Bridge Vertical Milling Machine Tools Spindle Kit 500W Air Cooled 05kw Milling Motor + Spindle Speed Power Converter + 52mm Clamp + 13pcs ER11 Collet + 10pcs Bits for DIY EngravingTFCFL Mill Machine Parts R8 Spindle + Bearings Assembly

The Best Milling Machine for Your Home Workshop Bob Vila

Vertical milling machines have a cutting tool mounted on a vertical spindle that can be raised or lowered This type of milling machine can drill or cut deeply into material, but it isn’t a good Milling Machine Spindle [Complete DIY Guide] [ Milling Machine Parts Home] The spindle is the heart of any mill It consists of a rotating assembly with a taper where tool holders may be installed A spindle motor with optional transmission of some kind rotates the C Milling Machine Spindle [Complete DIY Guide This is an economical and simple bed type mill for machining large work piece The model with 2 spindles can do 5 sided machining with the optional rotary table or indexer Vertical Spindles Vertical Spindles X Travel: 51–67 in Y Travel: 22–32 in Z Travel: 22–24 in Taper: NST 50: RPM: 6k: Tools: N/A: Vertical / Horizontal Vertical Knee Mills Sharp Industries Inc

Slide Vertical turret M3 milling machine R8 spindle head

Vertical turret M3 milling machine R8 spindle head NO3 mill machine Accessories Visit the store: https://sclickaliexpress/e/AbuSZR The third axis is provided by a vertical spindle (Zaxis) that moves up and down The mill can be used for milling slots, holes or pockets, drilling, profiling, boring and surfacing Most milling is done using “end mills” that look much like a drill bit except they are capable of cutting on the sides as well as on the endMilling Machine Terminology – Sherline ProductsMilling can be done with a wide range of machine toolsThe original class of machine tools for milling was the milling machine (often called a mill) After the advent of computer numerical control () in the 1960s, milling machines evolved into machining centers: milling machines augmented by automatic tool changers, tool magazines or carousels, capability, coolant systems, and enclosuresMilling (machining) Wikipedia

Milling Machine Accessories McMasterCarr

Convert a manual milling machine for horizontal operations For recesses, pockets, and workpieces that are too large or awkward to fit under a vertical mill, these attachments reduce the need for special tooling and fixturing by turning the spindle 90° so it operates parallel to the groundThe vertical milling machine spindle adopts energy consumption braking, and the braking torque is large, stopping quickly and reliably The main components such as base, fuselage, workbench, middle slide, lifting slide and headstock are all cast from highstrength materials and treated by artificial aging to ensure the stability of longterm Vertical Milling Machine MachineMfgThe horizontal axis spindle carrier 14 is disposed such that when moved to the lower extreme of its vertical travel, the vertical axis spindle carrier 15 may have essentially all of its normal vertical movement, and as such can address the workpiece for milling operations in the usual mannerMilling machine with horizontal and vertical spindles

What is Milling Machine Operation, Parts and Types

Dec 09, 2016 The milling machine in which the spindle axis is perpendicular to the table is called vertical milling machine 3 KneeType Milling Machine The milling machine which has a knee like projection at the middle is called kneetype milling machine It is characterised by a vertical adjustable work table resting on a saddle supported by a kneeThis attachment converts the horizontal spindle of a horizontal milling machine to a vertical spindle It is clamped to the column and driven from the horizontal spindle It incorporates provisions for setting the head at any angle, from the vertical to the horizontal, in a plane at right angles to the machine spindleHow to use a Milling Machine InstructionsMar 02, 2020 The other type is a turret mill, which comes with a bed and a fixed spindle that moves along both horizontally and vertically for positioning the material The following are the advantages that vertical milling offers: The visibility; Vertical milling machines offer users increased visibility because of the openness that comes with the orientationWhat are the Avantages of Milling: Benefit of Vertical and

10 Best Mini Milling Machine Reviews updated in March 2021

Mar 16, 2021 Vertical Milling Machine In this mill, the spindle has a perpendicular axis to the worktable A vertical milling machine, is hence, suitable for making horizontal cuts on the material Horizontal Mill Machine In this type of mill, the spindle is situated such that it’s horizontal to The third axis is provided by a vertical spindle (Zaxis) that moves up and down The mill can be used for milling slots, holes or pockets, drilling, profiling, boring and surfacing Most milling is done using “end mills” that look much like a drill bit except they are capable of cutting on the sides as well as on the endMilling Machine Terminology – Sherline ProductsPriest Tools designs and builds tooling and accessories for the vertical mill industry The products offered by Priest Tools originated by necessity and through a lack of available product in the market place Each tool was created from the machinist’ viewpoint and based on a Priest Tools Vertical Milling Machine Tools Accessories

Making a small milling head Practical Machinist

Jun 17, 2006 The vertical head on my Lewis, comparable in size to the Atlas, is plain bearing Takes an MT2 collet So clearly the plain bearing is an OK item Mine came to me pulleyed for up to about 2000 rpm, and I have run it that fast I will say that it has been months since I used it Now I just set up on the table with an end mill holder in the H Most heads are based on a Bridgeport design and have been cloned by Taiwanese and Chinese manufacturers The WellsIndex milling head is a much more robust and durable design for heavy cutting with most components such as the spindle diameter, bearings, gears, and splines being 40% to 100% larger than its competitorsWellsIndex Milling MachinesVertical milling machines have a cutting tool mounted on a vertical spindle that can be raised or lowered This type of milling machine can drill or cut deeply into material, but it isn’t a good The Best Milling Machine for Your Home Workshop Bob Vila

Horizontal vs Vertical Milling The Differences Explained

Jan 13, 2021 A vertical milling machine is the most commonly used type and features a vertically oriented cutting head or spindle, holding as well as rotating the cutting tool against the workpiece Since the cutting head is affixed in a vertical orientation, other machine parts will shift along a single or more axes to move the material in the right Bridgeport Type Vertical Mill (1) Bridgeport; Bridgeport Vertical Mills (1) Drawbars (1) Enco Model 4050593 (1) Horizontal Vertical Setup (1) Product Type Spindle Pulley Hub Machine/Machine Part Compatibility 20 HP B Series Mills Machine Part Compatibility Variable Speed Top Housing Milling Machine Parts Hardware MSC Industrial SupplyThe 860C converts in less than 5 minutes from horizontal to vertical (or vice versa) and simultaneously does vertical and horizontal milling The heavyduty horizontal Features allgear positive drive, with highinertia Flywheel, 3 hp variable speed drive with direct lever control, and #40 MMT taper spindle equipped with draw barVertical Milling — WellsIndex Milling Machines