عنا

مرحبا هل يمكنني مساعدتك؟

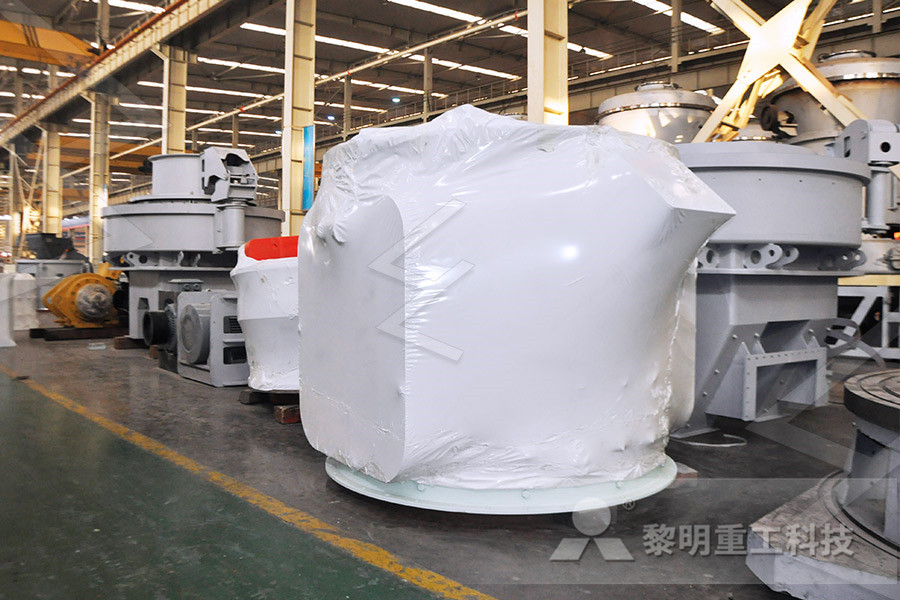

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

effect of limestone binder in iron ore pellets

2020-08-18T06:08:13+00:00

Effect of limestone and dolomite flux on the quality of

Feb 01, 2021 The addition of a binder, either organic or inorganic, provides adhesion to feed particles and increases the pellet strength Sometimes, the increase in the binder's dosage may affect the green pellet growth rate by producing smaller pellets [ 6 ] Over the years, bentonite has been a commonly used binder in the pelletization processAug 10, 2015 In this study, the effect of adding limestone on the metallurgical properties (reducibility, swelling, cracking, softening temperature, LowTemperature Disintegration, Cold Crushing Strength) of acid iron ore pellets was investigated using a Effect of adding limestone on the metallurgical properties Aug 10, 2015 In this study, the effect of adding limestone on the metallurgical properties (reducibility, swelling, cracking, softening temperature, LowTemperature Disintegration, Cold Crushing Strength) of acid iron ore pellets was investigated using a Effect of adding limestone on the metallurgical properties

Iron ore fluxed pellets and their physical properties

Jun 01, 1985 Effect of limestone addition Comparing iron ore and limestone pelletizing kinetics [8, 9], it was noticed that under proper pelletizing water range the rate of growth of limestone pellets is generally less than that of the iron ore pellets at high number of revolutionsJan 31, 2017 For agglomeration of these fines, a suitable binder is required Iron orecoal composite pellets were prepared by cold bonding Various binders such as lime, Ca(OH) 2, slaked lime, dextrose, molasses, and sodium polyacrylate (SPA), alone or in combination, were employed for making composite briquettes The slaked lime–dextrose combination Effects of Binder on the Properties of Iron OreCoal Different charge materials were used such as grade VK iron ore concentrate, limestone, bentonite and an organic binder of the polyacrylamide type The organic binder ensured the formation of a moreComposition of IronOre Pellets with Different Types of

Development on Iron Ore Pelletization Using Calcined Lime

In pelletization mainly limestone is used as source of CaO Its calcination is happened at elevated temperature during induration of pellet and provides CaO to form several calcium containing slag phases (Caferrites or silicates) that improves slag bonding and pellet propertiesMechanisms in wet iron ore green pellets with a bentonite binder” Powder Technology 169 ((2006) 147158 2 Coetsee T, Pistorius PC, Villiers EE D “Rate determining steps for reduction in magnetitecoal pellets” –, Minerals Engineering 15 (2002) 919929 3 Ripke SJ, Kawatra S K “Can flyash extend Bentonite binder for iron oreReduction Kinetics of iron ore pellets and effect of bindersJul 10, 2017 Bentonite, an inorganic binder, has been the main binder used in the iron ore pelletizing process since the beginning of pellet production in the 1950s Bentonite promotes the formation of ceramic bridges between particles, which can minimize the number of pellets that collapse during firingIron Ore Pelletizing Process: An Overview IntechOpen

Influence of flux additives on iron ore oxidized pellets

Aug 05, 2010 Six additives, ie, limestone, lime, magnesite, magnesia, dolomite and lightburneddolomite, were added for investigating their influences on the pellet quality For green balls, adding lime and lightburneddolomite makes the wet drop strength decrease firstly, and then increase with further increase of additive dosage Ca(OH)2 affects the bentonite properties at the beginning, but the Effect of the Addition of Organic Binders on the Behavior of Iron Ore Pellets In pelletizing limestone fines, it has been shown to be possible to use dispersants like soda ash, for this particular case, it was possible to make use of no binder and to work only with the dispersant This fact has been understood as a consequence of the Effect of the Addition of Organic Binders on the Behavior The binder mainly used for iron ore pellets was bentonite but due to its increasing costs substituting materials were used The limestone has a greater effect on the strength of the dry Composition of IronOre Pellets with Different Types of

Effects of Binder on the Properties of Iron OreCoal

Jan 12, 2010 For agglomeration of these fines, a suitable binder is required Iron orecoal composite pellets were prepared by cold bonding Various binders such as lime, Ca(OH) 2, slaked lime, dextrose, molasses, and sodium polyacrylate (SPA), alone or in combination, were employed for making composite briquettes The slaked lime–dextrose combination Mechanisms in wet iron ore green pellets with a bentonite binder” Powder Technology 169 ((2006) 147158 2 Coetsee T, Pistorius PC, Villiers EE D “Rate determining steps for reduction in magnetitecoal pellets” –, Minerals Engineering 15 (2002) 919929 3 Ripke SJ, Kawatra S K “Can flyash extend Bentonite binder for iron oreReduction Kinetics of iron ore pellets and effect of bindersThe iron ore was crushed , ground and screened to 100 # size and charcoal to 72 # size Pellets were made by hand rolling method by using water and different quantities of binder The pellets were fired at different firing temperature Each crucible containing iron ore pellets were placed in a furnaceREDUCTION KINETICS OF IRON ORE PELLETS AND THE

Effects of binders on balling behaviors of iron ore

An organic binder, Funa, has been developed and used in the production of iron ore pellets for direct reduction in China This paper mainly describes the effects of the binder on balling behaviors of magnetite concentrates as compared to bentonite binderSIVRIKAYA AROL (2014) ALTERNATIVE BINDERS TO BENTONITE FOR IRON ORE PELLETIZING PART II: EFFECTS ON METALLURGICAL AND CHEMICAL PROPERTIES O SIVRIKAYA1 and AI AROL2 1 Adana Science and Technology University, Faculty of Engineering and Natural Sciences, Dept of Mining and Mineral Processing Eng, 01180, Adana, Turkey, osmansivrikaya@gmail 2 Middle (PDF) ALTERNATIVE BINDERS TO BENTONITE FOR IRON ORE iron ore, water and a binder are balled in a mechanical disc or drum to produce wet pellets Bentonite is the most widely used binder in iron ore pelletizing industry The use of bentonite is favorable in terms of physical, mechanical and metallurgical pellet properties, however, because of its acid constituents (SiO 2 ALTERNATIVE BINDERS TO BENTONITE FOR IRON ORE

Effect of molasses binder on the physical and mechanical

AB Kotta et al, Effect of molasses binder on the physical and mechanical properties of iron ore pellets 43 Fig 2 Flow chart illustrating the preparation of molasses and iron ore pellets 22 Experimental contents and methods 221 Wet pellet preparation Pellets were prepared by mixing iron ore To process taconite, the ore is ground into a fine powder, the magnetite is separated from the gangue by strong magnets, and the powdered iron concentrate is combined with a binder such as bentonite clay and limestone as a flux As a last step, it is rolled into pellets about 10 millimeters in diameter that contain about 65% ironTaconite WikipediaMolasses was used as an alternative binder to the bentonite binder The change in moisture absorption by pellets prepared with different iron ores and different molasses contents were investigated Iron ore properties exerted the major effect on pellet behavior and final pellet quality The absorbed moisture content of pellets prepared without binder, bentoniteadded pellets, and molasses Effect of molasses binder on the physical and mechanical

Effect of Fluxing Agents on the Quality and Microstructure

Jun 01, 2017 Indian iron ore fines with high alumina content (~25% Al 2 O 3 ) resulted in poor quality pellets and a study was under taken to establish suitable pellet chemistry through proper fluxing agents Limestone fluxed pellets were prepared at varying basicity (0 to 08) and pyroxenite fluxed pellets at varying MgO contents (0 to 3%) to study their effect on the metallurgical propertiesWhich type of Iron ore is mixed with the binder in a balling drum to form pellets Taconite 2 What three materials are melted in a blast furnace Coke, limestone and iron ore 3 Which ingredient in a blast furnace combines with impurities to form slag Limestone 4 What type of furnace is used to convert iron ore to pig iron Basic oxygen furnace 8Chapter 5 and 6 Flashcards by Sheila Throckmorton BrainscapeThe present invention discloses a new process for the improvement of reducibility of iron ore pellets comprising the steps of i) preparing a raw material mixture which contain metallic Ni powder; ii) pelletizing the said mixture obtained; iii) burning the said raw pellets and iv) reducing the said burnt pellets under reducing conditions with presence of CH 4WOA1 Process for the improvement of

Effect of the Addition of Organic Binders on the Behavior

Effect of the Addition of Organic Binders on the Behavior of Iron Ore Pellets In pelletizing limestone fines, it has been shown to be possible to use dispersants like soda ash, for this particular case, it was possible to make use of no binder and to work only with the dispersant This fact has been understood as a consequence of the The iron ore was crushed , ground and screened to 100 # size and charcoal to 72 # size Pellets were made by hand rolling method by using water and different quantities of binder The pellets were fired at different firing temperature Each crucible containing iron ore pellets were placed in a furnaceREDUCTION KINETICS OF IRON ORE PELLETS AND THE @article{osti, title = {Organic binders for iron ore pelletization and steelmaking}, author = {Karkoska, D and Sankey, E and Anderson, R}, abstractNote = {Historically, bentonite has been used in the agglomeration process in North American iron ore plants In 1986, Eveleth Mines replaced bentonite with Peridur, a carboxy methyl cellulose organic binder used in conjunction with 1% anic binders for iron ore pelletization and steelmaking

ALTERNATIVE BINDERS TO BENTONITE FOR IRON ORE

iron ore, water and a binder are balled in a mechanical disc or drum to produce wet pellets Bentonite is the most widely used binder in iron ore pelletizing industry The use of bentonite is favorable in terms of physical, mechanical and metallurgical pellet properties, however, because of its acid constituents (SiO 2 One promising application is as a binder for iron ore pellets used, as blast furnace feed, to produce iron and steel The objective of this project was to investigate the use of highcarbon flyashes as iron ore pellet binders This is the first attempt to reuse high carbon flyash Iron ore pelletization is a high volume application; during HighCarbon FlyAsh as a Binder for Iron Ore Pellets,9/99 Carmeuse provides solutions to steel manufacturers by supplying high quality limebased products that help offset the continual degradation of iron ore quality Limestone/lime helps to remove impurities and it improves the physical and chemical properties of pellets Iron Ore Preparation Carmeuse

Effect of molasses binder on the physical and mechanical

AB Kotta et al, Effect of molasses binder on the physical and mechanical properties of iron ore pellets 43 Fig 2 Flow chart illustrating the preparation of molasses and iron ore pellets 22 Experimental contents and methods 221 Wet pellet preparation Pellets were prepared by mixing iron ore To process taconite, the ore is ground into a fine powder, the magnetite is separated from the gangue by strong magnets, and the powdered iron concentrate is combined with a binder such as bentonite clay and limestone as a flux As a last step, it is rolled into pellets about 10 millimeters in diameter that contain about 65% ironTaconite WikipediaJun 30, 2020 The minerals badly effected on the iron ore smelting are usually sulfur, phosphorus, potassium, sodium, lead, arsenic, zinc, titanium and copper Generally, they have the following bad effects on smelting: Elements that bad for iron ore smelting 1 Sulfur (S): it is the most harmful element to iron ore smelting It will make the steel with hot Adverse effects of 9 elements in iron ore on its smelting

Angle of Material Recommended Material Density Repose

Alfalfa Pellets 4143 2029° 2 Alfalfa Seed 1015 29° 2 Almonds, broken or whole 2830 3044° 3 Alum, Fine 4550 3044° 3 Alum, Lumpy 5060 3044° 3 Alumina 5065 22° 2 1012 *Aluminum chips 715 45° 4 Aluminum hydrate 18 34° 3 2024 Aluminum ore (see bauxite)BACKGROUND •This presentation is based on a manuscript Effect of Limestone Addition on the Metallurgical Properties of Iron Ore Pellets by Mikko Iljana a, Antti Kemppainena, Timo Paananen b, Olli Mattila , Erkki Pisilä b, Mikhail Kondrakov c and Timo Fabritius a submitted to the International Journal of Mineral Processing on 31th May 2014 a Research Group of Process Metallurgy, University EFFECT OF LIMESTONE ADDITION ON THE Effect of particle size on reduction behavior in iron orecoal composite pellets Yi Man, Junxiao Feng, Qi Ge and Fujie Li School of Mechanical Engineering, University of Science and Technology Beijing, Beijing, China ABSTRACT The reduction of iron orecoal composite pellets was carried out in the temperature range of 500 ~1200°C byEffect of particle size on reduction behavior in iron ore

Iron ore pelletizing Outotec

The iron is usually ground to a very fine level and mixed with limestone or dolomite as a fluxing agent and bentonite or organic binders as a binding agent If the ore is a Hematite ore, coke or anthracite coal can be added to the mix to work as an internal fuel to help fire the pelletsThe iron ore pelletizing process consists of three main steps: 1 Pelletizing feed preparation and mixing: the raw material (iron ore concentrate, additives anthracite, dolomite and binders are prepared in terms of particle size and chemical specifications, dosed, and mixed together to feed the pelletizing process; 2Iron Ore Pelletizing Process: An Overview