عنا

مرحبا هل يمكنني مساعدتك؟

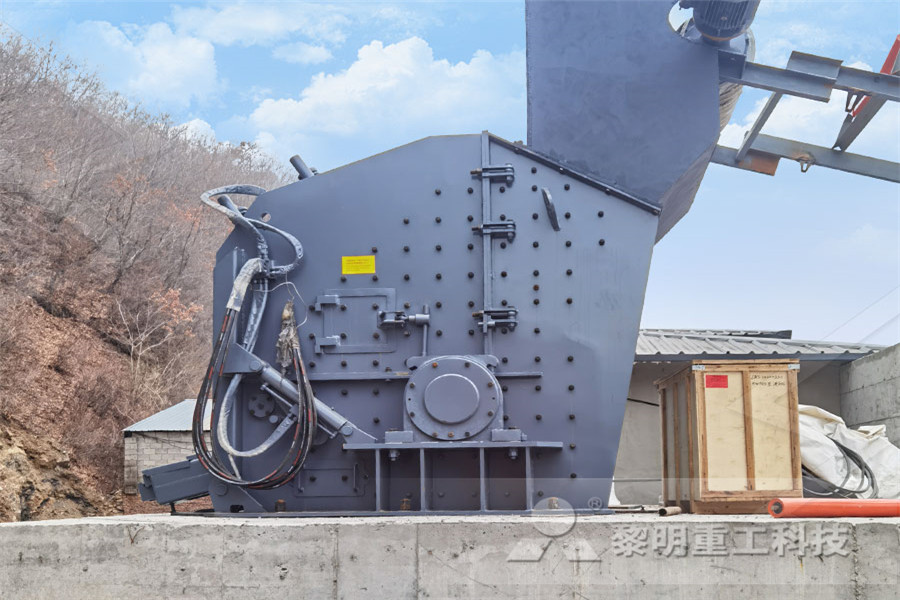

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

diffrent crushers and its working principle

2020-09-15T18:09:43+00:00

Working Principle of Crushers

Details the Working Principle of Crushers (Jaw and Gyratory) using mechanical animations and physicsApr 03, 2015 Crushers are classified into three types based upon the stage of crushing they accomplish These are (i) primary crusher, (ii) secondary crusher, and (iii) tertiary crusher The primary crusher receives material directly from run of mine (ROM) after blasting and produces the first reduction in sizeCrushers and Their Types – IspatGuruOperating Principal • In a cone crusher the stones are crushed with both SPB and IPB as the material moves down through the chamber • The relative amounts of IPB and SPB depends on factors like chamber design, crusher geometry, speed, css, eccentric throw, and othersCrushing Principles of Mechanical Crushing

different crushers and its working principle

Sep 20, 2017 In one respect, the working principle and appliion of this machine is similar to the Dodge crushers; the movable jaw has its maximum movement at the Since the jaw crusher was pioneered by Eli Whitney Blake in the the 2nd quarter of the 1800s, many have twisted the A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher WikipediaThe appearance and working principle of the 2 crushers are different The jaw crusher is of the curved dynamic extrusion type, and the materials are crushed in the crushing cavity composed of the moving jaw and the fixed jaw The hammer crusher is mainly broken by the impact, shear and tear of the rotating hammer head, the mutual impact between Hammer Crusher VS Jaw Crusher Which Is Better (7 Tips) MC

The Models And Parameters Of Cone Crusher

The difference in working principle When the singlecylinder hydraulic cone crusher is working, the motor drives the small gear of the crusher, the pinion drives the large gear, and the large gear assembly drives the eccentric sleeve assembly and the spindle assembly, which are centered on the theoretical vertical line, and rotate in the copper Metallurgical ContentJaw Crusher Designs Style for SaleJaw Crusher TerminologyJAW CRUSHERSDoubleToggle Jaw CrushersSingletoggle Jaw CrushersSizing Jaw CrushersForced Feed Jaw CrushersBulldog Jaw CrusherTraylor Jaw CrusherJaw Crusher Foolproof A sectional view of the singletoggle type of jaw crusher is shown below In one respect, the working principle and Jaw Crusher Working PrincipleThe two crushers can continuous working, and their working principle in the same way But the cone crusher vs gyratory crusher, their structure and performances are different Structure Different 1 Cone The cone liners of the gyratory crusher are steeply inclinedCone Crusher VS Gyratory Crusher JXSC Mine

Gyratory Crusher an overview ScienceDirect Topics

A jaw crusher crushes only a small proportion of the original aggregate particles but an impact crusher crushes mortar and aggregate particles alike and thus generates a higher amount of fine material (O’Mahony, 1990) Gyratory crushers work on the same principle as cone crushers (Figure 44(c)) These have a gyratory motion driven by an Dec 09, 2014 • Working Principle Of A Jaw Crusher • A jaw crusher uses compressive force for breaking of particle • A Jaw Crusher reduces large size rocks or ore by placing the rock into compression A fixed jaw, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the Jaw crusher SlideShareDifferent Crushers And Its Working Principle Principle Of Impact Crusher itlrcin working principles of washing machine jaw crusherimpact with the working principles of an mobile impact crusherimpact crushersimpact crusher for even though impact crushing machine of different manufacturers are different in model and mass their working principleCrushers Working Principle

(PDF) SIZE REDUCTION BY CRUSHING METHODS

Working Principle of Impact Stone Cru sher VSI crushers use a different approach inv olving a high speed rotor with wear resist ant tips and a The differences between jaw crusher and other secondary crusher Firstly, they differ in the working principle For jaw crusher, the driving power of the generator leads to the movement of the swing jaw and of the eccentric shaft and then the materials are crushed While the working principle of cone crusher is laminated crushingJaw Crusher With Different Models The primary gyratory crusher offers high capacity thanks to its generously dimensioned circular discharge opening (which provides a much larger area than that of the jaw crusher) and the continuous operation principle (while the reciprocating motion of the jaw crusher produces a batch crushing action)Crushers an overview ScienceDirect Topics

4 Types of Stone Crushers' Maintenance and Efficient

Jan 14, 2021 Horizontal Shaft Impact crusher (HSI) Impact crusher working animation The working principle of impact crusher is that the spinning rotor under the driving of the motor can genetate strong impact force which make blow bars crush stone material into small pieces Then the crushed material would be thrown by hammers towards, which makes another crushing process "stone to stone"Different Working Principle Jaw Crusher: The crushing chamber of jaw crusher is composed of fixed jaw plate and movable jaw plate The fixed jaw plate is fixed vertically on the fuselage body, and the movable jaw plate is in the inclined position The movable jaw plate continuously moves to the fixed jaw plate periodicallyJaw Crusher VS Cone Crusher Which Is The Better Crusher Sep 20, 2017 In one respect, the working principle and appliion of this machine is similar to the Dodge crushers; the movable jaw has its maximum movement at the Since the jaw crusher was pioneered by Eli Whitney Blake in the the 2nd quarter of the 1800s, many have twisted the different crushers and its working principle

4 Types of Stone Crushers' Maintenance and Efficient

Jan 14, 2021 Horizontal Shaft Impact crusher (HSI) Impact crusher working animation The working principle of impact crusher is that the spinning rotor under the driving of the motor can genetate strong impact force which make blow bars crush stone material into small pieces Then the crushed material would be thrown by hammers towards, which makes another crushing process "stone to stone"The appearance and working principle of the 2 crushers are different The jaw crusher is of the curved dynamic extrusion type, and the materials are crushed in the crushing cavity composed of the moving jaw and the fixed jaw The hammer crusher is mainly broken by the impact, shear and tear of the rotating hammer head, the mutual impact between Hammer Crusher VS Jaw Crusher Which Is Better (7 Tips) MCThe differences between jaw crusher and other secondary crusher Firstly, they differ in the working principle For jaw crusher, the driving power of the generator leads to the movement of the swing jaw and of the eccentric shaft and then the materials are crushed While the working principle of cone crusher is laminated crushingJaw Crusher With Different Models

Cone Crusher VS Gyratory Crusher JXSC Mine

The two crushers can continuous working, and their working principle in the same way But the cone crusher vs gyratory crusher, their structure and performances are different Structure Different 1 Cone The cone liners of the gyratory crusher are steeply inclinedThe primary gyratory crusher offers high capacity thanks to its generously dimensioned circular discharge opening (which provides a much larger area than that of the jaw crusher) and the continuous operation principle (while the reciprocating motion of the jaw crusher produces a batch crushing action)Cone Crusher an overview ScienceDirect TopicsIn terms of working principle, the crushing chamber of a general wood pulverizer generally only has a set of independent cutting devices, namely a cutter disc, hammers, and a screen The multifunctional wood shredder has two sets of independent cutting devices under different inlets Therefore, it has a higher working efficiencyMultifunctional Wood Crusher Straw Branch Shredder

(PDF) SIZE REDUCTION BY CRUSHING METHODS

Working Principle of Impact Stone Cru sher VSI crushers use a different approach inv olving a high speed rotor with wear resist ant tips and a Working principle of Grinding Machine: The working principle of a grinding machine is quite easier to understand In a grinding machine, there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley So when we start the electric motor the motor rotates at a certain rpm (15015000 RPM, it may change according to the types of grinding Grinding Machine: Types, Parts, Working Operations (With Figure 12: Different steps of building the model individual work Make a working drawing in 2D of what you will add to the structure so that it cannot collapse or topple over The drawing accurately shows the design you that sketched on page 92 (2) The drawing shows all important dimensions (2) The drawing is to scale, and the scale is shown (1)Gr8 Technology mstworkbookscoza

Crusher Machine For Sale in Philippines Jaw/Cone/Impact

Crusher Machine For Sale in the Philippines Crusher machine for sale is the mechanical equipment used to crush minerals Generally, a crushing machine can crush different materials, such as river pebbles, granite, limestone, basalt, ore, rock, stone, gypsum, coal, etcAccording to the feed particle size and discharge size, the process of crushing includes three stages, coarse crushing, medium 4 Different Working Principle a When jaw crusher working, the motor drives the belt and pulley to move the moving jaw up and down through the eccentric shaft When the moving jaw rises, the angle between the elbow plate and the moving jaw increases, so as Jaw Crusher VS Impact Crusher What's The Difference MCAug 03, 2020 They have different applications in production The material that can be processed and the working principle in the production of the material are different, so the equipment is changed The mobile crusher plant station is also pided into many different types Next we will make a detailed analysis of these reformed production equipment 1different types of mobile crushers for mineral processing

Jaw Crusher Primary Crusher in Mining Aggregate JXSC

JXSC jaw type rock crusher is usually used as a primary crusher and secondary crusher to reduce the size of mediumhard materials to smaller physical size Jaw rock crushers are capable of working with the mobile crushing station, underground crushing because of its related small volume Capacity: 11120TPH Max Feeding Size: 1201200mm Application