عنا

مرحبا هل يمكنني مساعدتك؟

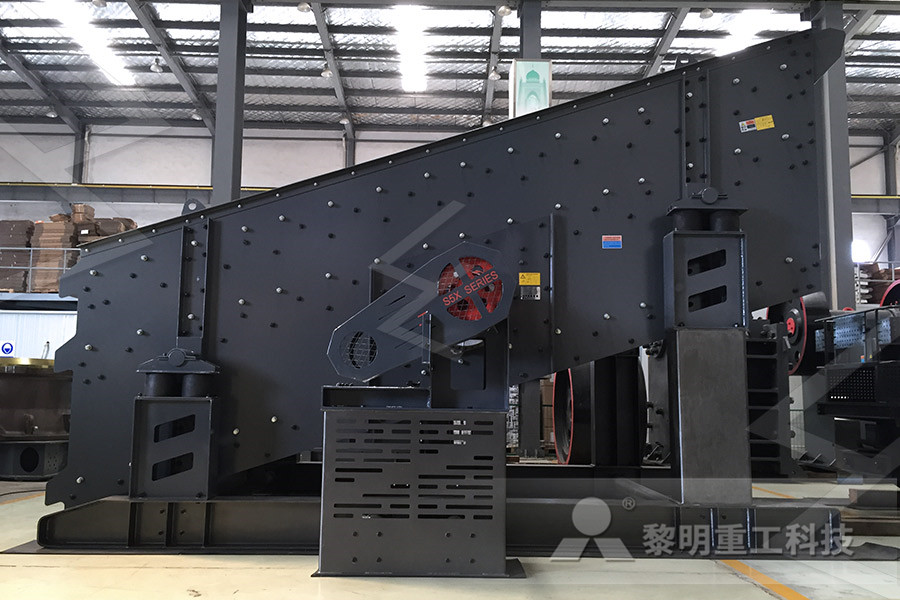

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

electrochemical grinding ac

2020-08-08T21:08:28+00:00

Electrochemical Grinding (ECG) Glebar Company

The Burr Free Electrochemical Point Grinding System from Tridex Technology is a fully programmable pointing and material handling system designed to manufacture a wide variety of medical device points on tubing or solid wire using the ECG process Visit Tridex Technology's YouTube Channel for video demonstrations PGS100Jul 28, 2020 In Electrochemical grinding, the metal bonded grinding wheel filled with a nonconductive abrasive The grinding wheel act as a cathode and the workpiece is act as an anode The electrolyte, which is usually sodium nitrate, sodium chloride, potassium nitrite, with a concentration of 0150 to 0300 kg/litre of waterElectrochemical Grinding: Working, Application, Advantages Electrochemical Grinding Advanced Medical Components (AMC) specializes in electrochemical grinding of high quality, tight tolerance metal components to specification for large medical device OEMs AMC equipment is available for high precision, burrfree grindingElectrochemical Grinding AMC Contract Manufacturer

Electrochemical Grinding (ECG) Wytech

The electrochemical grinding process combines traditional electrochemical machining and grinding processes to remove material from a workpiece With its burrfree cutting, tight tolerance capabilities and workability with stainless steel and other medical grade alloys, ECG is an integral technology in Wytech’s manufacturing platformOur latest Electrochemical Grinding (ECG) equipment is high precision, burrfree grinding machinery with controllable heal rounding for noncoring, and the ability to machine hard material such as spring temper, profile grinding shavers, etcElectrochemical Grinding (ECG) Cadence IncFeb 16, 2016 Electrochemical grinding (ECG) Prof SAVAN FEFAR Electrochemical grinding (ECG) Prof SAVAN FEFAR 2 • The process is similar to cathode is a specially constructed grinding wheel instead of a cathodic shaped • The insulating abrasive material (diamond or aluminum oxide) of the grinding wheel is set in a conductive bonding • the wheel is Electrochemical grinding (ecg) SlideShare

electrochemical grinding SlideShare

Feb 16, 2017 • Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive grinding wheel, an electrolyte fluid, and a positively charged workpiece • Materials removed from the workpiece stay in the electrolyte fluidOct 30, 2018 What is Electrochemical Grinding and How it Works? Electrochemical Machining (ECM) – Working Principle, Equipment, Advantages and Disadvantages with Application Here, in the above process one thing to be note down is that there is a use of Direct Current (DC) and not an Alternating Current (AC) The speed of the electrochemical What is Electrochemical Deburring? Mechanical BoosterElectrochemical Grinding (ECG) AC7116/2 Rev C Δ1 Electrical Discharge Machining (EDM) AC7116/3 RevC Δ1 Laser Beam Machining (LBM) AC7116/4 Rev D Δ1 Posted Laser Part Marking (LPM) AC7116/5 Rev A Δ1 Spark Erosion Grinding (SEG) AC7116/6 Rev A Δ1 Abrasive Water Jet Machining (AWJM) AC7116/7 NA Δ1 LINK AC Checklists posted on JAQG Web AC Checklists posted on JAQG Web

(PDF) Electrochemical dressing of grinding wheels using

The paper deals with a newly developed method for electrochemical dressing of metal bonded superabrasive wheels In this method, alternating current derived from a wall outlet via an inexpensive 2Electrochemical Grinding (ECG) 1In ECG , the material removal is achieved by combined action of abrasive and electrochemical process energy The resulting surface has high surface integrity, is burr free, and has negligible distortion 2The abrasive particles of the grinding wheel make a contact with the workpiece and the gap between theChapter 5One of the machining process alternatives is electrochemical machining (ECM) Electrochemical grinding (ECG) is one of the examples of ECM which is a combination of conventional grinding and ECM processes ECG has an up to 5%:95% grinding ratio of conventional grinding to ECM The price of an ECG machine in the market reaches 53 million rupiahsBuild and Design Electrochemical Grinding Machine with 100

Introduction of hybrid machining: Fabrication and

Nov 30, 2020 Electrochemical grinding is a combined type hybrid process, in which a conventional grinding wheel superimposed with electrolysis effect The conventional grinding wheel of metallic bond used in ECG because the abrasive bonded with metal work as an abrasion and simultaneously the metal structure of wheel perform electrolysisElectrochemical Grinding process Control Panel Effect of parameter on current density; Effect of current density on MRR; Effect of voltage for different depths of cuts Effect of voltage for different electrolytes Effect of voltage for different electrolytes concentrations ) : Electrochemical Grinding mmcoepvlabsacElectrochemical grinding (ECG) is one of the examples of ECM which is a combination of conventional grinding and ECM processes ECG has an up to 5%:95% grinding ratio of conventional grinding to ECM The price of an ECG machine in the market reaches 53 million rupiahs In the NonConventionalRANCANG BANGUN MESIN ELECTROCHEMICAL

Surface finish in electrochemical grinding and pulsed

Surface finish in electrochemical grinding and pulsed electrochemical grinding FadaieTehrani, A; Atkinson, John In: Proceedings of the 13th International Symposium for Electromachining, Bilbao: Proceedings of the 13th International Symposium for Electromachining, Bilbao; 2001 p 881892Electrical Engineering Assignment Help, Application of electrochemical grinding, Explain the working principle, Surface finish, material removal, accuracy,advantages and application of Electrochemical Grinding(ECG) (a) In electro chemical machining of pure iron a material removal rate of 600mm 3 /min is required Estimate curApplication of electrochemical grinding, Electrical VII ELECTROCHEMICAL GRINDING (ECG)Electrochemical Grinding is a variety of ECM that consolidates electrolytic movement with the physical evacuation of material by use of charged grinding wheels It can deliver burr and stretch free parts without any metallurgical harm brought on by grinding, wiping out the need for secondary machining operations(PDF) ElectroChemical Machining DrNanjundeswaraswamy T

GT9AC Guidewire Grinding Machine

The GT9AC is designed to grind medical guidewires with multiple tapers, paddles, and even parabolic shapes, with the ability to update the linear position of the wire every 000025" (0006 mm) at grinding speeds superior to traditional centerless grindingElectrochemical grinding The main feature of electrochemical grinding (ECG) is the use of a grinding wheel in which an insulating abrasive, One form of this process relies on a pulsed direct current, that is, fullwave rectified ac power supply that is locked in phase with a vibrating tool head The oscillation of the tool gives rise to a Electrochemistry Encyclopedia Electrochemical machiningElectric Discharge Grinding , Electric Discharge Diamond Grinding , and Wire Electric Discharge Machining: Download: 14: Electrochemical Machining (ECM) Download: 15: Electrochemical Grinding , Electrostream Drilling, Shaped Tube Electrolytic Machining: Download: 16: Plasma Arc Machining (PAM) Download: 17: Electron Beam Machining (EBM) Edit NPTEL :: Mechanical Engineering NOC:Advanced Machining

AC Checklists posted on JAQG Web

Electrochemical Grinding (ECG) AC7116/2 Rev C Δ1 Electrical Discharge Machining (EDM) AC7116/3 RevC Δ1 Laser Beam Machining (LBM) AC7116/4 Rev D Δ1 Posted Laser Part Marking (LPM) AC7116/5 Rev A Δ1 Spark Erosion Grinding (SEG) AC7116/6 Rev A Δ1 Abrasive Water Jet Machining (AWJM) AC7116/7 NA Δ1 LINK AC Checklists posted on JAQG Web One of the machining process alternatives is electrochemical machining (ECM) Electrochemical grinding (ECG) is one of the examples of ECM which is a combination of conventional grinding and ECM processes ECG has an up to 5%:95% grinding ratio of conventional grinding to ECM The price of an ECG machine in the market reaches 53 million rupiahsBuild and Design Electrochemical Grinding Machine with 100 2Electrochemical Grinding (ECG) 1In ECG , the material removal is achieved by combined action of abrasive and electrochemical process energy The resulting surface has high surface integrity, is burr free, and has negligible distortion 2The abrasive particles of the grinding wheel make a contact with the workpiece and the gap between theChapter 5

(PDF) ElectroChemical Machining DrNanjundeswaraswamy T

VII ELECTROCHEMICAL GRINDING (ECG)Electrochemical Grinding is a variety of ECM that consolidates electrolytic movement with the physical evacuation of material by use of charged grinding wheels It can deliver burr and stretch free parts without any metallurgical harm brought on by grinding, wiping out the need for secondary machining operationsThe article describes a process of electrochemical grinding (ECG – Electrochemical Grinding) with a rectangular diamond grinding wheel made of ceramic – tungsten frit Treatment of this type of material is very difficult, not only because of adverse physical properties of material itself but also due to very high requirements resulting from Electrochemical ECG grinding of ceramic and tungsten Electrochemical grinding (ECG) is one of the examples of ECM which is a combination of conventional grinding and ECM processes ECG has an up to 5%:95% grinding ratio of conventional grinding to ECM The price of an ECG machine in the market reaches 53 million rupiahs In the NonConventionalRANCANG BANGUN MESIN ELECTROCHEMICAL

Simulation and experimental investigation of innerjet

Electrochemical machining (ECM) has become a common method for machining this alloy and other difficulttomachine materials Electrochemical grinding (ECG) is a hybrid process combining ECM and conventional grinding In this paper, investigations conducted on innerjet Jul 25, 2020 Electrochemical grinding (ECG) Thermoelectric energy based unconventional machining IonBeam machining (IBM) Plasma ARC machining (PAM) It consists of an electromechanical transducer which is connected to an AC supply The velocity transformer which holds the tool firmly An abrasive gun is used to supply an abrasive slurry, which is a 9 Types of Unconventional Machining Processes Working PDFelectrochemical forming process The noteworthy feature of electrolysis is that electrical energy is used to produce a chemical reaction, therefore, the machining process based on this principle is known as Electrochemical machining (ECM) This process works on the ELECTRO CHEMICAL MACHINING

Nadcap Nonconventional Machining AC7116

We have training courses for each Nadcap Nonconventional Machining standard (Nonconventional Machining, Electrochemical Machining, Electrochemical Grinding, Electrical Discharge Machining, Laser Beam Machining, Laser Part Marking, Spark Erosion Grinding) The duration ranges from a couple hours to a full dayDr Divyansh Patel has specialization in the field of microtexturing of biomedical implants using electrochemical micromachining He has also carried out research work on various advanced (nontraditional) machining processes such as Electrochemical Grinding, Abrasive Water Jet Machining, Laser Surface Texturing, Electric Discharge Machining, etc during his M Tech and PhD programsProfile Birla Institute of Technology and Science, PilaniElectrochemical Machining Processes Electrochemical Machining (ECM) Electrochemical Deburring (ECD) Electrochemical Grinding (ECG) III Thermal Energy Processes Thermal Energy Processes Electric Discharge Processes Slide 21 EDM Applications Wire EDM Laser Beam Machining (LBM) Plasma Arc Cutting (PAC) IV Chemical Machining (CHM)NONTRADITIONAL MACHINING AND THERMAL

Investigation on ColorFinishing Process Conditions for

Jan 01, 2004 Figure 2 shows the proposed electrical grinding system and Figure 3 a shows schematic illustration showing electrochemical reactions in the grinding process [5] In this system, an electrode of about 116th of the area of the entire grinding wheel surface is set above a conducting metallic bonded grinding wheel with a gap of about 01 mmElectrochemical Grinding (ECG) ECG is the result of hybridizing ECM with the abrasive action of conventional grinding to machine hard and fragile electrically conducting materials efficiently, economically and productively without affecting the useful properties of these materialsChapter 2