عنا

مرحبا هل يمكنني مساعدتك؟

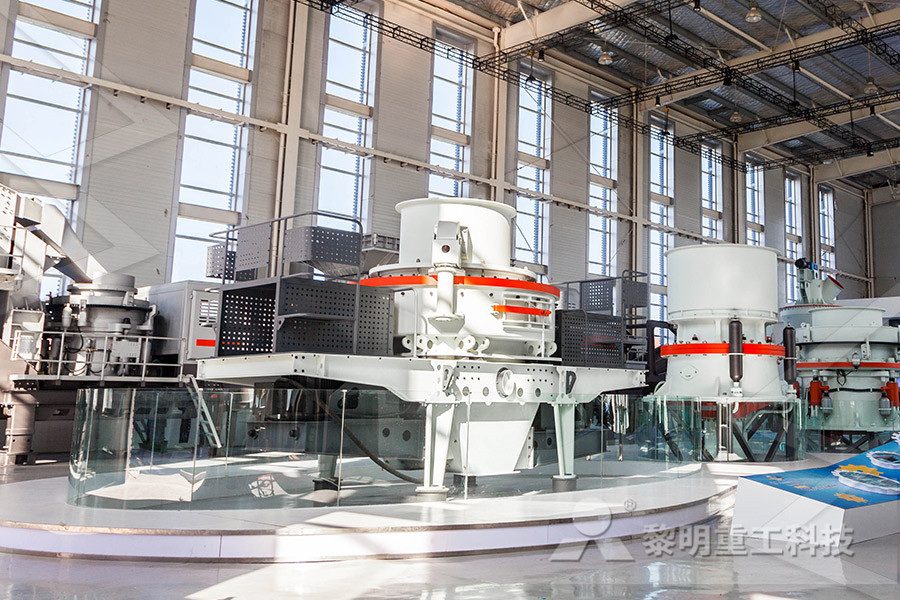

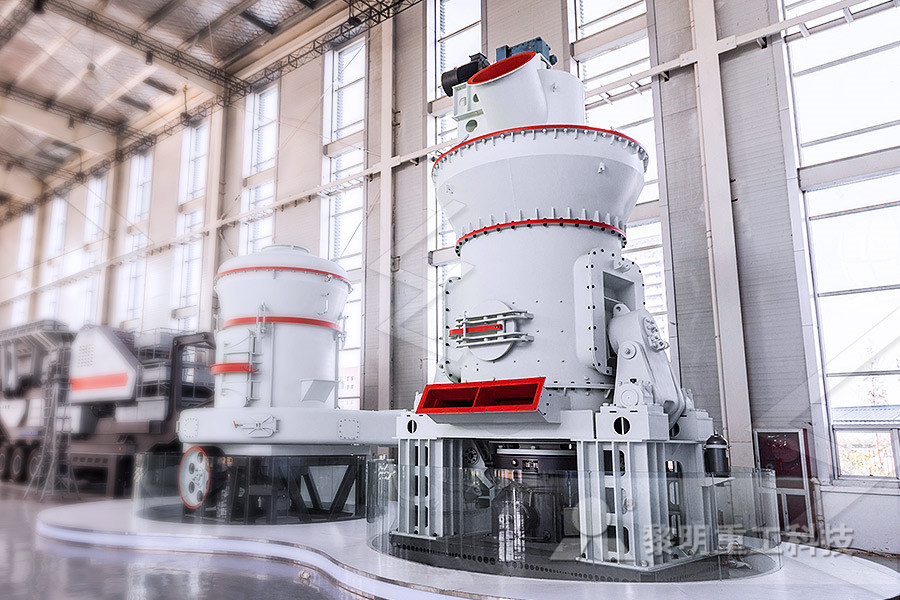

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

al gasification and the environment

2022-05-24T22:05:00+00:00

Coal gasification: The clean energy of the future? BBC News

Apr 14, 2014 First, coal gasification actually produces more CO2 than a traditional coal plant; so not only will China be using more coal, it will be doing so at a greater cost to the environmentThermal alteration of the overburden rock caused by high gasification temperatures may lead to swelling and further reduce the free volume left after coal extraction The ε UCG requirement of containing gas in the coal seam during the gasification leads to gasification of rather deep coal Underground Coal Gasification and EnvironmentMay 15, 2014 Coal gasification, the technology for highefficient utilization of coal, has been widely used in China However, it suffers from high CO 2 emissions problem due to the carbonrich character of coal To reduce CO 2 emissions, different CO 2 capture technologies are developed and integrated into the coal gasification based processesEnvironmental impact and technoeconomic analysis of the

Coal Gasification

In the gasifier, crushed coal is combined with steam at high pressure and temperature The quantity of oxygen is limited to prevent complete combustion of the coal Instead, the carbon reacts with the steam to form a mixture of CO, H2, and other gases There is always some combustion, so some CO2is formedCoal gasification is economically attractive, but has significant CO2 emissions, even if CO 2 can be captured and stored Nowadays, hydrogen production from coal gasification is not much used, except in those places where the other sources are very expensive (Dagdougui, 2012)Coal Gasification an overview ScienceDirect TopicsApr 23, 2019 Specifically, mixtures of coal and crop residues are used as fuel inputs to an integrated gasification combined cycle (IGCC) system to produce electricity Through this process, CO 2 emissions are concentrated and ready for CCS (hereafter referred to as CBECCS to signify coal and biomass energy inputs) This pathway has multiple advantagesGasification of coal and biomass as a net carbonnegative

65 Emissions Advantages of Gasification netldoegov

Gasificationbased processes for power production characteristically result in much lower emissions of pollutants compared to conventional coal combustionEach segment of the coal system has some kind of environmental problem—from coal extraction, via preparation, to processing and utilization Coal utilization processes in industry mainly include combustion and gasification for generating electricity, process heat and residential heat as well as carbonization for making metallurgical coke, andEnvironmental Problems Arising from Coal Handling and Coal is an abundant fuel source that is relatively inexpensive to produce and convert to useful energy However, producing and using coal affects the environment Effects of coal mining Surface mines (sometimes called strip mines) were the source of about 62% of the coal minedCoal and the environment US Energy Information

Environmental Issues in Underground Coal Gasification

Environmental Issues in Underground Coal Gasification (with Hoe Creek example) Elizabeth Burton, PhD Julio Friedmann, PhD Ravi Upadhye, PhD, PETHE PEMBINA INSTITUTE UNDERGROUND COAL GASIFICATION v Executive Summary dro) is used to break up (fracture) the rock Once the two wells are connected, the operator ignites the coal and then controls its gasi"cation by varying the amount of air let in and the amount of gas that exits Figure 1 depicts the gasi"cation processUnderground Coal GasiÞcation Environmental Risks and Compared to a coal combustion plant, a gasification plant produces smalleramounts ofthe traditional air pollutants, such as particulates, COx'SOx'NOx and hydrocarbons The prominent gaseous effluents of coal gasification facilities consist ofH2S,COS, S02 and NH 3, Among the secondary air pollutants, which occur in gaseous streams inEnvironmental Impacts of Coal Utilization on the Ecosystem

Coal Gasification

Coal Gasification: Water Gas Reaction There are several steps in coal gasification Let's focus on step 1: conversion of the solid coal to a burnable gas In the gasifier, crushed coal is combined with steam at high pressure and temperature The quantity of oxygen is limited to prevent complete combustion of the coalGasificationbased processes for power production characteristically result in much lower emissions of pollutants compared to conventional coal combustion This can be traced to the fundamental difference between gasification and combustion: in combustion, air and fuel are mixed, combusted and then exhausted at near atmospheric pressure, while in gasification oxygen is normally supplied to the 65 Emissions Advantages of Gasification netldoegovThe United States Department of Energy’s Office of Fossil Energy, through the Gasification Systems Program, is developing flexible, innovative, resilient, and transformative modular designs for converting diverse types of US domestic coal and coal blends with biomass, municipal solid waste (MSW), and waste plastics into clean synthesis gas to enable the lowcost production of electricity Gasification Systems Department of Energy

Clean Coal Technologies Carbon Capture and Storage CCS

Gasification converts the coal to burnable gas with the maximum amount of potential energy from the coal being in the gas In Integrated Gasification Combined Cycle (IGCC) the first gasification step is pyrolysis, from 400°C up, where the coal in the absence of oxygen rapidly gives carbonrich char and hydrogenrich volatilesEach segment of the coal system has some kind of environmental problem—from coal extraction, via preparation, to processing and utilization Coal utilization processes in industry mainly include combustion and gasification for generating electricity, process heat and residential heat as well as carbonization for making metallurgical coke, andEnvironmental Problems Arising from Coal Handling and The DOE Gasification Systems Program is developing innovative modular designs for converting diverse types of coal into clean synthesis gas to enable the lowcost production of electricity, transportation fuels, chemicals, hydrogen, and other useful products to suit market needs Advancements in this area will help enable advanced power generation and other syngasbased technologies to be Gasification Systems netldoegov

Coal Gasification – University of Kentucky Center for

Coal gasification is a thermochemical process in which heat and pressure break down coal into its basic chemical constituents The resulting “syngas” is comprised primarily of carbon monoxide and hydrogen, and occasionally other gaseous compoundsCoal gasification, Coal gasification Publisher Toronto, Ont : The Ministry Collection omote; toronto; governmentpublications Digitizing sponsor Ontario Council of University Libraries and Member Libraries Contributor Ontario Ministry of the Environment Language English Volume 2Inventory of coal gasification plant waste sites in Before the Indonesian government pumps money into gasification, they might want to take a look at what happened in the US not so long ago Back in the 2000s, the American coal industry was pushing to build gasification plants to turn coal into a liquid gas that, they claimed, could be used in chemicals and even for transportation as an alternative to imported oil and thenexpensive natural gasThe Dumb Dream of Turning Coal to Gas Just Won't Die

Coal pollution mitigation Wikipedia

Coal pollution mitigation, sometimes called clean coal, is a series of systems and technologies that seek to mitigate the health and environmental impact of coal; in particular air pollution from coalfired power stations, and from coal burnt by heavy industry The primary focus is on sulfur dioxide (SO 2) and nitrogen oxides (NO x), the most important gases which caused acid rain; and Environmental Issues in Underground Coal Gasification (with Hoe Creek example) Elizabeth Burton, PhD Julio Friedmann, PhD Ravi Upadhye, PhD, PEEnvironmental Issues in Underground Coal GasificationCompared to a coal combustion plant, a gasification plant produces smalleramounts ofthe traditional air pollutants, such as particulates, COx'SOx'NOx and hydrocarbons The prominent gaseous effluents of coal gasification facilities consist ofH2S,COS, S02 and NH 3, Among the secondary air pollutants, which occur in gaseous streams inEnvironmental Impacts of Coal Utilization on the Ecosystem

Coal and the environment US Energy Information

Coal is an abundant fuel source that is relatively inexpensive to produce and convert to useful energy However, producing and using coal affects the environment Effects of coal mining Surface mines (sometimes called strip mines) were the source of about 62% of the coal minedCoal gasification is a thermochemical process in which heat and pressure break down coal into its basic chemical constituents The resulting “syngas” is comprised primarily of carbon monoxide and hydrogen, and occasionally other gaseous compoundsCoal Gasification – University of Kentucky Center for Gasification converts the coal to burnable gas with the maximum amount of potential energy from the coal being in the gas In Integrated Gasification Combined Cycle (IGCC) the first gasification step is pyrolysis, from 400°C up, where the coal in the absence of oxygen rapidly gives carbonrich char and hydrogenrich volatilesClean Coal Technologies Carbon Capture and Storage CCS

Coal pollution mitigation Wikipedia

Coal pollution mitigation, sometimes called clean coal, is a series of systems and technologies that seek to mitigate the health and environmental impact of coal; in particular air pollution from coalfired power stations, and from coal burnt by heavy industry The primary focus is on sulfur dioxide (SO 2) and nitrogen oxides (NO x), the most important gases which caused acid rain; and The United States Department of Energy’s Office of Fossil Energy, through the Gasification Systems Program, is developing flexible, innovative, resilient, and transformative modular designs for converting diverse types of US domestic coal and coal blends with biomass, municipal solid waste (MSW), and waste plastics into clean synthesis gas to enable the lowcost production of electricity Gasification Systems Department of EnergyEach segment of the coal system has some kind of environmental problem—from coal extraction, via preparation, to processing and utilization Coal utilization processes in industry mainly include combustion and gasification for generating electricity, process heat and residential heat as well as carbonization for making metallurgical coke, andEnvironmental Problems Arising from Coal Handling and

Waste Conversion: The Benefits of Gasification Waste

Oct 30, 2015 With coalfired power plants releasing potentially hazardous chemicals and threatening the environment, operators around the world seek new ways to generate electricity and other forms of energy Processes such as gasification provide more environmentally friendly, economically beneficial methods for producing energyAfter over a century of coal ash and colliery waste dumping, the Tyne and Wear coastline is no stranger to industrial pollution But soon a horrific new technology underground coal gasification (UCG) will endanger human health and the environment, backed by unflinching Government support and generous lashings of taxpayers' money'Underground coal gasification' hellfires threaten EPA600/777045 May 1977 INSITU COAL GASIFICATION: STATUS OF TECHNOLOGY AND ENVIRONMENTAL IMPACT by 9 Nancy P Phillips and Charles A Muela Radian Corporation PO Box 9948 Austin, Texas 78766 Contract No 68022147, Exhibit A Program Element No EHE623A EPA Project Officer: William J Rhodes Industrial Environmental Research Laboratory Office of Energy, InSitu Coal Gasification: Status of Technology and

Shell coal gasification plant (SCGP1) environmental

Abstract Environmental studies in slipstream process development units at SCGP1, Shell's advanced coal gasification demonstration plant, located near Houston, Texas, have demonstrated that the gas and water effluents from the Shell Coal Gasification Process (SCGP) are environmentally benign on a broad slate of coalsCOAL GASIFICATION PLANTS I RECOMMENDATIONS FOR A COAL GASIFICATION STANDARD The National Institute for Occupational Safety and Health (NIOSH) recommends that employee exposure to toxicants and hazardous conditions in coal gasification plants be controlled by adherence to the following sections The recommended standard is designed toCoal Gasification PlantsGasification of coal and biomass as a net carbonnegative power source for environmentfriendly electricity generation in China Xi Lua,b,1, Liang Caoa,b,c, Haikun Wangd, Wei Penge,f, Jia Xinga,b, Shuxiao Wang a,b, Siyi Cai , Bo Sheng, Qing Yangh,i,j, Chris P Nielsenj, and Michael B McElroyj,k,1 aState Key Joint Laboratory of Environment Simulation and Pollution Control, School of Environment Gasification of coal and biomass as a net carbonnegative