عنا

مرحبا هل يمكنني مساعدتك؟

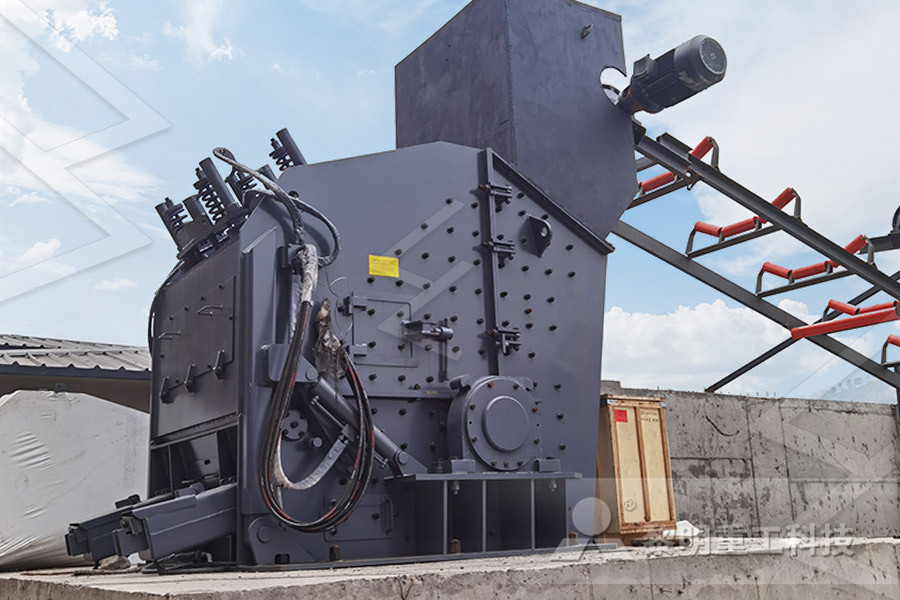

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

crushing of mining iron ore

2021-07-04T10:07:06+00:00

Iron Mining Process Minnesota Iron

Iron Mining Process From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation’s steelCrushing Asmined iron ore contains lumps of varying size, the biggest being more than 1 metre (40 inches) across and the smallest about 1 millimetre (004 inch) The blast furnace, however, requires lumps between 7 and 25 millimetres, so the ore must be crushed to reduce the maximum particle sizeIron processing Ores BritannicaIron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel Raw iron is alloyed with a variety of elements (such as tungsten, manganese, nickel, vanadium, chromium) to strengthen and harden it, making useful steel for construction, automobiles, and other forms of transportation such as trucks Iron Ore Minerals Crushing in Mining JXSX Mine

Challenges and opportunities in the iron ore crusher

Before dry selection, the lean iron ore requires millimeterscale fine crushing by the fine crusher If the particle size of the iron ore is not small enough in the crushing stage, lowgrade iron ore is difficult to be selected later, which will cause serious waste of resources The selection of iron ore crusherApr 03, 2015 blasting, crushing, Hematite, Iron ore, magnetite, open pit mining, screening, underground mining, Understanding Iron Ores and Mining of Iron Ore Iron (Fe) is an abundant and a widely distributed element in the in the crust of the earth, constituting on an average ranging from 2 % to 3 % in sedimentary rocks to 85 % in basalt and gabbroUnderstanding Iron Ores and Mining of Iron Ore – IspatGuruMar 14, 2014 In the process of mining ore benches are developed for the purpose of drilling, blasting and hauling of the ore to the crushing plant The height of the benches is dependent on several factors such as output requirement, shape, size and depth of occurrence of ore body, geological disturbance suffered by the ore body, hardness and compactness of Mining of Iron Ores – IspatGuru

What is iron ore crushing and processing? Quora

Iron ore is an important raw material of steel producersAfter crushing, grinding, magnetic separation, flotation, reelection and other procedures,natural minerals (iron ore)elected gradually of iron Iron exist in nature all in compounds state, especially in the state of iron oxide but has more impuritiesIn mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surface Less abrasive and softer rocks or stones Crushing in Mineral ProcessingIron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel Raw iron is alloyed with a variety of elements (such as tungsten, manganese, nickel, vanadium, chromium) to strengthen and harden it, making useful steel for construction, automobiles, and other forms of transportation such as trucks Iron Ore Minerals Crushing in Mining JXSX Mine

Iron Ore Crusher Mining, Crushing, Grinding, Beneficiation

Iron Ore Crushing Machine Iron ore refers back to the ore containing iron or iron compound, which is one of the most important garbage in output of steel There are many largescale iron ore area which have high value of exploitation australia wide, Brazil, India, Apr 03, 2015 blasting, crushing, Hematite, Iron ore, magnetite, open pit mining, screening, underground mining, Understanding Iron Ores and Mining of Iron Ore Iron (Fe) is an abundant and a widely distributed element in the in the crust of the earth, constituting on an average ranging from 2 % to 3 % in sedimentary rocks to 85 % in basalt and gabbroUnderstanding Iron Ores and Mining of Iron Ore – IspatGuruMar 14, 2014 In the process of mining ore benches are developed for the purpose of drilling, blasting and hauling of the ore to the crushing plant The height of the benches is dependent on several factors such as output requirement, shape, size and depth of occurrence of ore body, geological disturbance suffered by the ore body, hardness and compactness of Mining of Iron Ores – IspatGuru

Iron ore Wikipedia

Mining of banded iron formations involves coarse crushing and screening, followed by rough crushing and fine grinding to comminute the ore to the point where the crystallized magnetite and quartz are fine enough that the quartz is left behind when the resultant powder is passed under a magnetic separatorIron mining in the United States produced 48 million metric tons of iron ore in 2019 Iron ore was the thirdhighestvalue metal mined in the United States, after gold and copper Iron ore was mined from nine active mines and three reclamation operations in Michigan, Minnesota, and UtahMost of the iron ore was mined in northern Minnesota's Mesabi RangeIron mining in the United States WikipediaThe world will need iron ore for as long as the world needs steel In 2020, we produced around 280 million tonnes of iron ore That's enough to make the steel for more than 3,300 Sydney Harbour Bridges We're building a new iron ore mine in Western Australia When completed, South Flank will produce highquality iron ore for around 25 yearsIron ore BHP

Benson Mines Wikipedia

The Benson Mine is an ironore mine located near Star Lake, a village in the southern St Lawrence County, New York The ore body at Benson Mine was discovered in 1810 by engineers conducting a survey for a new military road from Albany to Ogdensburg In the 1950s, mine was considered the largest open pit ironore mine in the worldOct 08, 2011 Iron Ore mining in the Plibara region of Western Australia near Newman The Mt Whaleback, Yandi, and Area C mines are shownIron ore mining YouTubeJaw Crusher vs Impact Crusher In short, the jaw stone crushers are mainly used for primary crusher, the crushing stone is relatively large The types of crusher machine's chamber are deep and no dead zone It improves that the feeding capacity and output The crushing ratio is large and the product particle size is evenJaw Crusher Primary Crusher in Mining Aggregate JXSC

Simulation Modeling of an Iron Ore Operation to Enable

An iron ore mining company, operating in Western Australia, trucks ore from three geographi cally isolated sources to a crusher, where it is blended before and during crushing The companyConventional opencut mining methods including drilling, blasting, loading and hauling are used to mine iron ore from the Sino deposit The pit will be approximately 500mdeep Processing facilities at the mine site include a crusher, a concentrator, and a 6mt pelletising plant Sino Iron employed some of the world’s biggest haul trucks and Sino Iron Project, Cape Preston Mining TechnologyIron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron oreIron Ore Processing,Crushing,Grinding Plant Machine Desgin

Iron ore crushing plant, iron ore beneficiation and mining

Mining and processing of iron ore involves coarse crushing and screening Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening This is usually so efficient that lower grade ore can be treated especially when the magnetite is quite coarse Common iron ore crushers are jaw crusher, cone Mining and processing of iron ore involves coarse crushing and screening Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening This is usually so efficient that lower grade ore can be treated especially when the magnetite is quite coarse Common iron ore crushers are jaw crusher, cone Iron ore crushing plant, iron ore beneficiation and mining Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel Raw iron is alloyed with a variety of elements (such as tungsten, manganese, nickel, vanadium, chromium) to strengthen and harden it, making useful steel for construction, automobiles, and other forms of transportation such as trucks Iron Ore Minerals Crushing in Mining JXSX Mine

Understanding Iron Ores and Mining of Iron Ore – IspatGuru

Apr 03, 2015 blasting, crushing, Hematite, Iron ore, magnetite, open pit mining, screening, underground mining, Understanding Iron Ores and Mining of Iron Ore Iron (Fe) is an abundant and a widely distributed element in the in the crust of the earth, constituting on an average ranging from 2 % to 3 % in sedimentary rocks to 85 % in basalt and gabbroMining of banded iron formations involves coarse crushing and screening, followed by rough crushing and fine grinding to comminute the ore to the point where the crystallized magnetite and quartz are fine enough that the quartz is left behind when the resultant powder is passed under a magnetic separatorIron ore Wikipedia411 Iron Ore Mining There are two basic methods of mining iron ore These are: • Surface mining or openpit mining • Underground or shaft mining To be competitive, iron mining must be done on a very large scale Surface mining is the preferred choice, although there are exceptions Small, lowcapacity mines have rapidly disappearedEnergy and Environmental Profile of the US Mining

Iron mining in the United States Wikipedia

Iron mining in the United States produced 48 million metric tons of iron ore in 2019 Iron ore was the thirdhighestvalue metal mined in the United States, after gold and copper Iron ore was mined from nine active mines and three reclamation operations in Michigan, Minnesota, and UtahMost of the iron ore was mined in northern Minnesota's Mesabi RangeAn iron ore mining company, operating in Western Australia, trucks ore from three geographi cally isolated sources to a crusher, where it is blended before and during crushing The companySimulation Modeling of an Iron Ore Operation to Enable After many years of hard work, a process was developed to create taconite pellets Taconite saved Minnesota's iron ore mining industry Learn more about Taconite from Minnesota History Center The Hull Rust Mahoning Mine in Hibbing, Minnesota World's largest open pit iron ore mine; First ore shipments in 1895 (still being mined today, 114 Taconite Minnesota DNR

Major Mines Projects Tilden Mine

Operations consist of a single stage crushing, AG mills Liberating the iron mineral requires that the crude ore be ground to the consistency of face powder This process begins in the same way for both magnetite (metallic gray, below) and hematite (redbrown, below) as crude ore and water are fed into large primary autogenous millsMar 15, 2021 Iron ore is a mineral block found underground It is smelted into iron ingots, which are used to make tools and armor Deepslate iron ore is a variant found in the deepslate layer of the world, below y=0[upcoming: JE 117] 1 Obtaining 11 Breaking 12 Natural generation 121 Caves Cliffs generation 2 Usage 21 Smelting ingredient 22 Note Blocks 3 Sounds 4 Data values 41 ID 5 Video 6 Iron Ore – Official Minecraft WikiIron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron oreIron Ore Processing,Crushing,Grinding Plant Machine Desgin

Iron ore mining process and iron ore mining equipments

Mining and processing of iron ore involves coarse crushing and screening Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening This is usually so efficient that lower grade ore can be treated especially when the magnetite is quite coarseIron ore is an important raw material in steel production enterprises After been crushing , grinding, magnetic separation, flotation, reelection and other procedures, iron will be gradually separated from natural minerals (iron ore) Iron ore is the mineral aggregates of iron element or iron compound which can be used economicallyOre CrusherIron Ore Mining ProcessIron Ore Crushing Iron ore is an important raw material for iron and steel production enterprises After crushing, grinding, magnetic separation, gravity concentration etc, gradually we can get iron from natural minerals (iron ore) It is the mineral aggregates that contain iron or iron compounds which can be used economically Production Process of Iron Ore Iron Ore,Production Process of Iron Ore,Iron Ore