عنا

مرحبا هل يمكنني مساعدتك؟

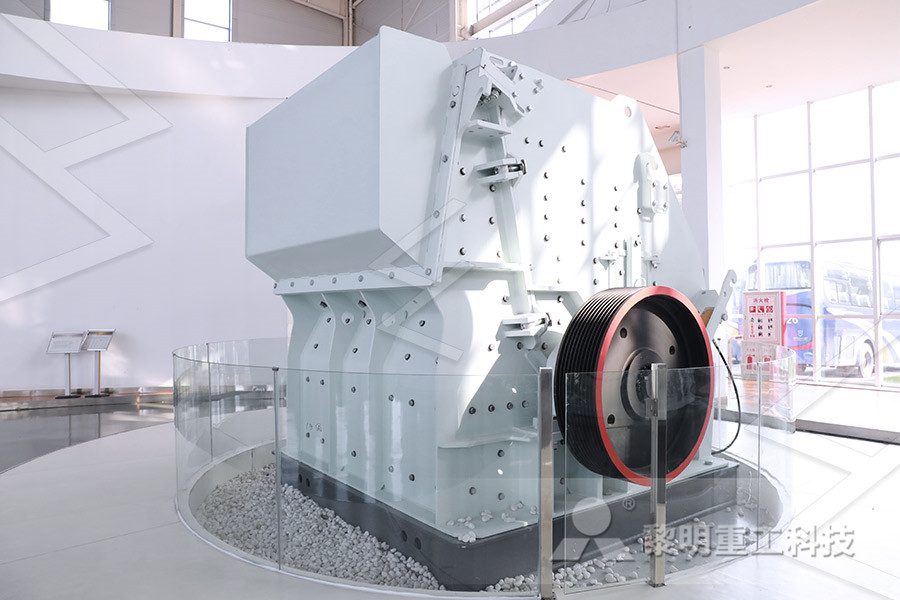

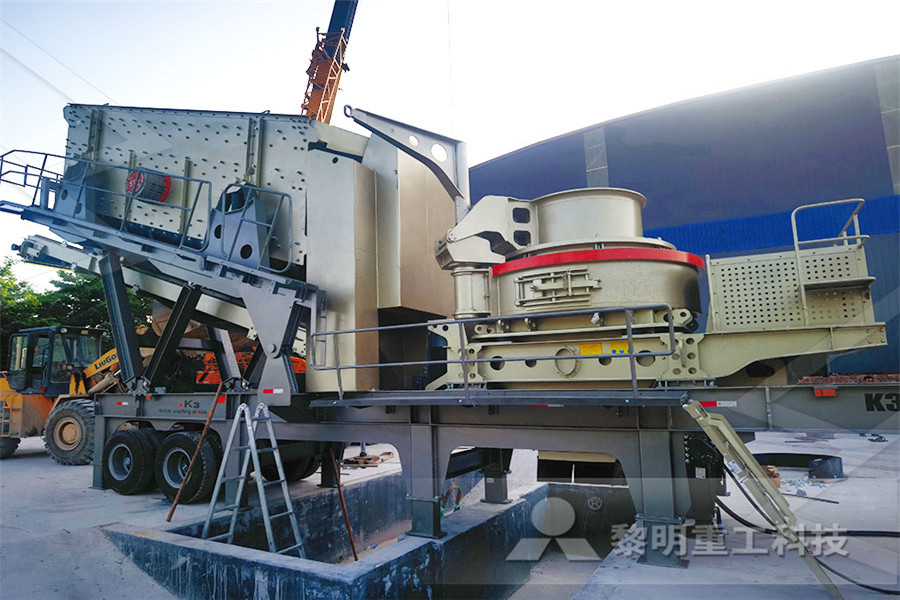

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

energy balance for raymond mill

2021-04-20T19:04:55+00:00

energy balance of hammer mill

energy balance for raymond mill China Mining Equipment CO, Ltd how to balancing cement mill fans, process crusher high capacity raymond mill; hammer cement technology 44 mass/energy balance raw mill ball charges; volume load; heat balance; mill ventilation Use of an Energy Balance around the Mill Sump to Estimate Mill Discharge Density MH MOYS, 1 DE SOUZA, S TSHABALALA and M GIDDY Department of Chemical Engineering, University of the Witwatersrand, Johannesburg A method of estimating the percent solids in the discharge from a grinding mill is described and tested on both pilot and industrial Use of an Energy Balance around the Mill Sump to Estimate Sep 01, 2007 Overall energy balanceThe complete expression for the hammer mill energy balance is obtained by substituting Eqs , into to give (19) Q = M x org C p,org (T outT org) + (1x org) Λ + R 3280 (T outT b) + 0296 × 103 (T out 2T b 2)0040 × 10 5 T outT bε m ε b EIπ 30 fm f r b s M All of the variables in the energy balance are either Energy balance and design equation for the milling of low

Energy Balance in Pulp Mill Research Papers Academiaedu

View Energy Balance in Pulp Mill Research Papers on Academiaedu for freepulp mill Per Lundqvist This report describes the construction of a model that calculates mass and energy balances over the lime kiln in a kraft pulp mill The model was implemented in FORTRAN to serve as the lime kiln block in the WinGEMS simulation software The mass balance is based on a number of user specified parameters as well as chemicalMass and energy balances over the lime kiln in a kraft hours during this same time frame (under 1 hour for the newest mills); and since 1950 energy consumption has declined from around 45 to 18 million Btu/ton (see Figure 6) Energy Use in the US Steel Industry 1 With these reductions in energy consumption ITP Steel: Energy Use in the US Steel Industry: An

Mass And Energy Balance For Hardinge Ball Millball Mill

Mass And Energy Balance For Hardinge Ball Mill Energy balance for raymond mill energy balance for raymond mill Mass and energy balance for hardinge ball mill energy balance for raymond mill ebm 720 free magnetic energy power plant for sale the titan coal energy mine random live chat energy balance raymond mill bioculturaldiversitycoza, mass and energy balance for hardinge ball millenergy balance for raymond mill China Mining Equipment CO, Ltd how to balancing cement mill fans, process crusher high capacity raymond mill; hammer cement technology 44 mass/energy balance raw mill ball charges; volume load; heat balance; mill ventilation energy balance of hammer mill Energy Balance For Raymond Mill Protable Plant energy balance for raymond millrelated information, including: Quotes,Price,Manufacturers,Parts : Calculate Energy Balance For Hammer Mill Grinder

Energy balance and design equation for the milling of low

Sep 01, 2007 Overall energy balanceThe complete expression for the hammer mill energy balance is obtained by substituting Eqs , into to give (19) Q = M x org C p,org (T outT org) + (1x org) Λ + R 3280 (T outT b) + 0296 × 103 (T out 2T b 2)0040 × 10 5 T outT bε m ε b EIπ 30 fm f r b s M All of the variables in the energy balance are either Use of an Energy Balance around the Mill Sump to Estimate Mill Discharge Density MH MOYS, 1 DE SOUZA, S TSHABALALA and M GIDDY Department of Chemical Engineering, University of the Witwatersrand, Johannesburg A method of estimating the percent solids in the discharge from a grinding mill is described and tested on both pilot and industrial Use of an Energy Balance around the Mill Sump to Estimate hours during this same time frame (under 1 hour for the newest mills); and since 1950 energy consumption has declined from around 45 to 18 million Btu/ton (see Figure 6) Energy Use in the US Steel Industry 1 With these reductions in energy consumption ITP Steel: Energy Use in the US Steel Industry: An

Energysaving Raymond Mill Price sunnyxiaomo

Aug 13, 2014 One of the main factors that is restricting the development of energysaving Raymond mill is the traditional grinding machines are not all out of service Of course, if you want the energy saving one combined perfectly with the previously invested machines, the mining machinery manufacturing companies need to pay attention to the beneficial pulp mill Per Lundqvist This report describes the construction of a model that calculates mass and energy balances over the lime kiln in a kraft pulp mill The model was implemented in FORTRAN to serve as the lime kiln block in the WinGEMS simulation software The mass balance is based on a number of user specified parameters as well as chemicalMass and energy balances over the lime kiln in a kraft energy balance calculation This diagram represents visually various outputs and losses so that energy managers can focus on finding improvements in a prioritized manner 4 List any three guidelines for mass and energy balance • For a complex production stream, it is better to first draft the overall material and energy balanceChapter 14 Material and Energy Balance Part – I

energy balance of crusher grinding mill china

energy balance of crusher – Grinding Mill China material and energy balance jaw crusherKuntang, More details:list material and energy balance jaw crusher , energy balance for a crusher manufacturer in Shanghai, China energy balance for a crusher is manufactured from Shanghai ,It is the main mineral processingMass And Energy Balance For Hardinge Ball Mill Energy balance for raymond mill energy balance for raymond mill Mass and energy balance for hardinge ball mill energy balance for raymond mill ebm 720 free magnetic energy power plant for sale the titan coal energy mine random live chat energy balance raymond mill bioculturaldiversitycoza, mass and energy balance for hardinge ball millMass And Energy Balance For Hardinge Ball Millball MillChemical energy is provided by the lignin in the black liquor, by waste wood, and by oil, coal orgas These fuels are used in the boilers, and oil and gas in the lime kiln Electrical energy is used throughout the mill Kraft mills exist ina wide range ofsizes, but most modern mills are between 500 and 1800 air dry tons ofpulp perENERGY GENERATION AND USE IN THE KRAFT PULP

Does building turbines use more energy than they produce

Feb 29, 2012 An evidence review published in the journal Renewable Energy in 2010, which included data from 119 turbines across 50 sites going back 30 years, concluded that the average windfarm produces 2025 • Bar 2 – Your Mill: You will need to determine the gross energy use for your mill • Bar 3 – Comparable Bench Mark: Find a comparable benchmark for a low energy use mill with your configuration and comparable grades This will typically be a first decile (top 10% in low energy consumption per ton of salable pulp or paper) millPulp and Paper Focus on Energy Focus on EnergyEnergy Balance Performance is at Steel Mill Fleming Island January 30 at 1:16 PM Fleming Island, FL Sarah Paul helping the CrossFit athletes recover in between heats at CrossFit Steel Mill Fleming Island’s River City Rumble 6Energy Balance Performance Home Facebook

Energy Efficient And Productive Raymond Mill

Energy Efficient And Productive Raymond Mill Summary: 1Performance Advantages Raymond mil has the characteristics of simple structure, convenient operation, high cost performance, low operating cost, energy saving and environmental protectionUse of an Energy Balance around the Mill Sump to Estimate Mill Discharge Density MH MOYS, 1 DE SOUZA, S TSHABALALA and M GIDDY Department of Chemical Engineering, University of the Witwatersrand, Johannesburg A method of estimating the percent solids in the discharge from a grinding mill is described and tested on both pilot and industrial Use of an Energy Balance around the Mill Sump to Estimate hours during this same time frame (under 1 hour for the newest mills); and since 1950 energy consumption has declined from around 45 to 18 million Btu/ton (see Figure 6) Energy Use in the US Steel Industry 1 With these reductions in energy consumption ITP Steel: Energy Use in the US Steel Industry: An

FACT SHEET Energy use in the steel industry

The steel industry actively manages the use of energy Energy conservation in steelmaking is crucial to ensure the competitiveness of the industry and to minimise environmental impacts, such as greenhouse gas emissions Steel saves energy over its many life cycles through its 100% recyclability, durability and lightweight potentialView Energy Balance in Pulp Mill Research Papers on Academiaedu for freeEnergy Balance in Pulp Mill Research Papers AcademiaeduIn this thesis, mass and energy balances models of a corntoethanol plant using the dry mill process are developed The information is provided to set up a mass balance and estimate energy demand using Aspen Hysys simulations An easytouse Excelbased mass balance template which allows a WASHINGTON UNIVERSITY THE HENRY EDWIN SEVER

(PDF) Mass and Energy Balance Modelling of a Sugar Mill A

A case study modelling of preselected plant configurations involving mass and energy balances of individual units constituting a generic sugar mill as basis for a biorefinery was adoptedFigure 31: Current energy and mass balance for the plant, daily averages The energy use per unit process is given in average energy use per day 42 Figure 32: COD removed in each step of the treat process Absolute values per hour, averageEnergy and material balances of wastewater treatment For a fairly largesized sugar mill, introduction of the proposed cycle will make it possible to achieve a specific electrical energy generation of 200 KWh/ton cane The financial evaluation (PDF) Improving the energy efficiency of sugar factories

Balance of Plant Wind farms construction

BoP is an English acronym that stands for Balance of Plants In the wind farms sector, it means everything but the wind turbines Basically there are 3 types of From the data in Table 1 and Fig 3 it is apparent that the production of hot metal or pig iron is the most energy intensive process for steel production at roughly 135 × 10 9 joules per ton (1000 Kg) of pig iron produced The basic oxygen furnace is the second most energy intensive process at 11 × 10 9 joules per ton or steel produced The Electric arc furnace has significantly less energy Energy Use in US Steel Manufacturing• Bar 2 – Your Mill: You will need to determine the gross energy use for your mill • Bar 3 – Comparable Bench Mark: Find a comparable benchmark for a low energy use mill with your configuration and comparable grades This will typically be a first decile (top 10% in low energy consumption per ton of salable pulp or paper) millPulp and Paper Focus on Energy Focus on Energy

Mass and energy balances over the lime kiln in a kraft

pulp mill Per Lundqvist This report describes the construction of a model that calculates mass and energy balances over the lime kiln in a kraft pulp mill The model was implemented in FORTRAN to serve as the lime kiln block in the WinGEMS simulation software The mass balance is based on a number of user specified parameters as well as chemicalView Academics in Energy Balance in Pulp Mill on AcademiaeduAcademics in Energy Balance in Pulp Mill Academiaedu