عنا

مرحبا هل يمكنني مساعدتك؟

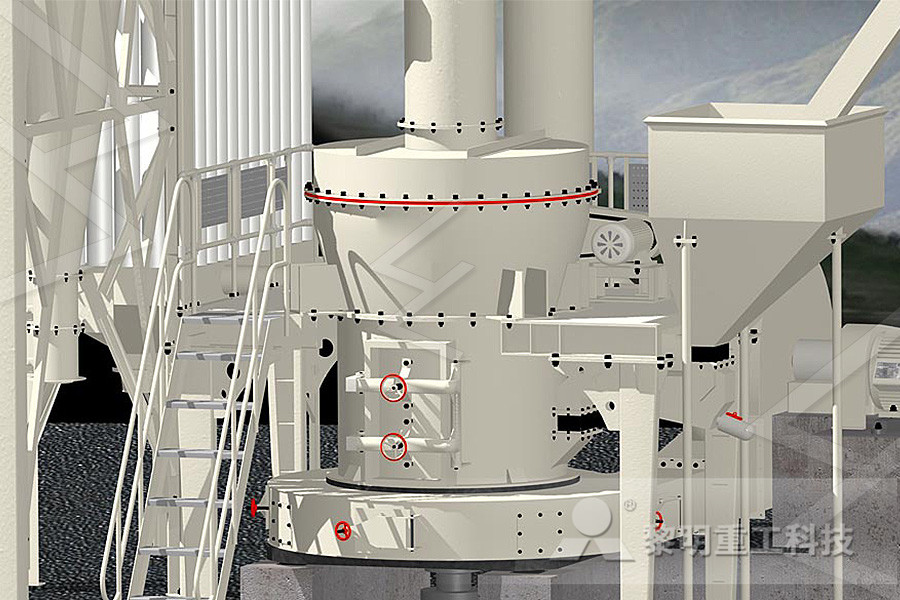

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

steel slag processing equipment 86

2021-02-28T07:02:59+00:00

The Best Steel Slag Production Line Equipment Made By HCM

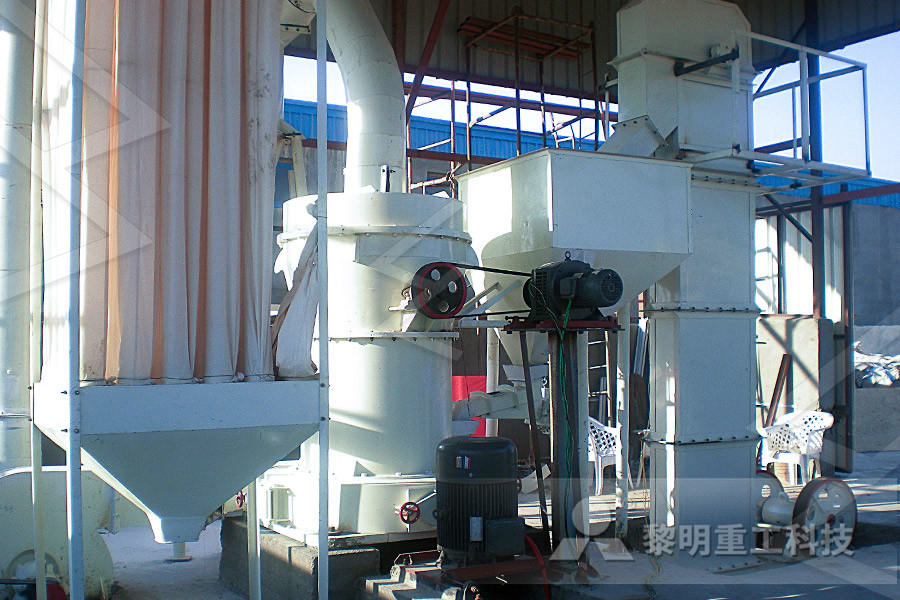

In the process of steel production, how to deal with the steel slag produced by refining?HCM new HLM vertical roller mill can be used in the field of comprehensive utilization of solid waste slag in steel plant, contributing to the transformation of solid waste slag into treasure HCM grinding mill HLM vertical roller mill equipment 〖 Product fineness 〗: 22180μmSteel slag produced from basic oxygen and electric arc furnaces accounted for the or reprocessing old slag piles at about 129 processing plants (including some iron and steel plants with more than one slagprocessing manufacture of iron and steel 2619000000 Free 86 Prepared by Kenneth C Curry [(703) 648–7793, ] 86 IRON AND STEEL SLAG USGSSteel slag i ntroduction: The steel slag crushing production line is a production line for recycling and recycling of steel slag and other resources based on the characteristics of steel slag hardness and rationally equipped equipmentDewo provides customers with technical services and design of 30800tph steel slag processing line!Steel slag processing dewomachinery

Steel Slag Briquetting Machine YUKE

The steel slag briquetting machine is a trustworthy industrial waste processing equipment designed for handling large volumes of steel powder and slag produced in steel making, with the purpose of making full use of these wastes and creating more valueSteel slag processing The steel slag is a main waste residue of iron and steel enterprise Currently, long distance with advance technology of steel slag recycling, simple recycling processing, high energizing consumption and low efficiency, a lot of steel slag is not efficient recycledSteel slag, Manufacturers, WholesalersSteel slag crushing production line adopts jaw crusher for primary crushing, and uses hydraulic cone crusher for secondary and tertiary crushing, offering high crushing efficiency, low wear, energy saving and environmental protection, it has the features of high automation, low operation cost and reasonable allocation of equipmentSteel Slag Processing SHANGHAI SANME MINING MACHINERY

Steel slag recycling Great Wall Corporation

The steel slag vertical mill, independently designed and manufactured by Great Wall Machinery, is the special equipment for milling water slag, steel slag and other industrial slag into powder size It is the excellent equipment for producing steel slag powder in the processing The company developed dry process and wet process techniques for steel slag recycling The technique with the capacity of 300,0002,000,000 t/a could be utilized by steel slag processing plant to reach integrated and high efficient use and zero emission, lead to recycling development of steel enterprises, ensure the high efficient and energy saving technique and equipment for the enterprisesIntroduction of integrated and efficient steel slag Steel slag produced from basic oxygen and electric arc furnaces accounted for the or reprocessing old slag piles at about 129 processing plants (including some iron and steel plants with more than one slagprocessing manufacture of iron and steel 2619000000 Free 86 Prepared by Kenneth C Curry [(703) 648–7793, ] 86 IRON AND STEEL SLAG USGS

Steel Slag Briquetting Machine YUKE

The steel slag briquetting machine is a trustworthy industrial waste processing equipment designed for handling large volumes of steel powder and slag produced in steel making, with the purpose of making full use of these wastes and creating more valueSteel slag is a common industrial solid waste What kind of grinding mill is suitable for grinding steel slag powder? As a wellknown steel slag mill manufacturer in Guilin, China, HCMilling(Guilin Hongcheng) provides environmental protection vertical roller mill equipment for customers according to the market prospect of industrial solid waste recyclingSteel Slag Grinding Mill Manufacturer Professional SupplierFor many years, CHAENG specializes in customizing cast steel slag pots /slag ladles of various specifications and types according to drawings Its rich manufacturing experience, strong processing equipment and professional flaw detection system have laid the foundation for the production of high quality slag pots /slag ladlesslag pot Xinxiang Great Wall Casting Co, Ltd steel

Steel Slag Processing SHANGHAI SANME MINING MACHINERY

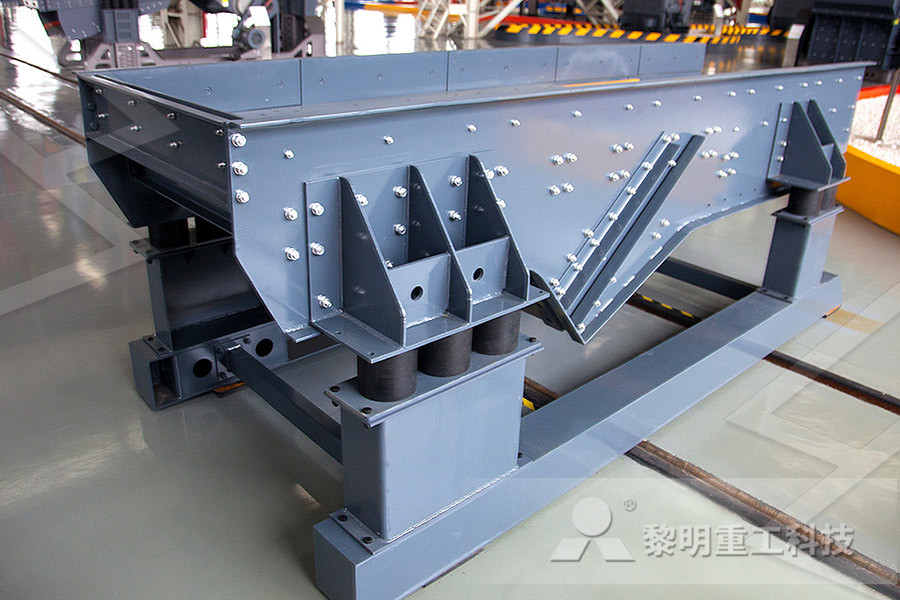

Steel slag crushing production line adopts jaw crusher for primary crushing, and uses hydraulic cone crusher for secondary and tertiary crushing, offering high crushing efficiency, low wear, energy saving and environmental protection, it has the features of high automation, low operation cost and reasonable allocation of equipmentThe company developed dry process and wet process techniques for steel slag recycling The technique with the capacity of 300,0002,000,000 t/a could be utilized by steel slag processing plant to reach integrated and high efficient use and zero emission, lead to recycling development of steel enterprises, ensure the high efficient and energy saving technique and equipment for the enterprisesIntroduction of integrated and efficient steel slag The steel slag vertical mill, independently designed and manufactured by Great Wall Machinery, is the special equipment for milling water slag, steel slag and other industrial slag into powder size It is the excellent equipment for producing steel slag powder in the processing Steel slag recycling Great Wall Corporation

Steel Mill Services Construction Equipment

Stein provides Slag Processing and Steel Mill Services including Slag Handling, Scrap Handling, various Steel Mill Services, Sales of Aggregate Material and Construction EquipmentAug 27, 2020 To achieve an annual output of 1 million tons of slag powder processing capacity, the slag grinding equipment operates for 300 days a year, running for about 24 hours a day, and the main machine type of the equipment slag grinding equipment is mainly GRMS5341 slag vertical mill, plus Other auxiliary machines such as dust removal, conveying Open a slag powder grinding and processing plantannual Heavy slag (also known as dross) is an issue usually associated with flame cutting or plasma cutting plate steel A machine configured for slag grinding is capable of removing this difficult burr in a single pass! This refined slag removal process can save your operators significant time and boost their overall efficiency while simultaneously increasing the quality and consistency of your Removing Heavy Slag Effortlessly Timesavers, LLC

Scrap Processing Scrap Metal Services Steel Mill

Our range of services includes, but is not limited scrap yard management, finished or semifinished product services, melt shop services, logistics/transportation support, and slag processing Founded more than a decade ago, Scrap Metal Services is a leader in the industry, prioritizing recycling and environmental safety, and handling all Steel slag is the solid waste produced during the steel making process and about 100150kg steel slag is produced per ton of steel The utilization of steel slag is getting more and more attention in the world large processing capacity, high processing precision 3Low maintenance cost, more stable running Main equipment: 32×13m Steel slag grinding plant CHAENGSlag Removal Stein utilizes slag pot haulers to remove slag from our customers' melt shops At the steelmakers request, we have direct furnace digging capabilities with enhanced frontend specialty loaders These specialty loaders are also used in digging the blast furnace pits at our integrated locationsSlag Contractor – Slag Removal Construction Equipment

slag processing and applications

Steel slag i ntroduction: The steel slag crushing production line is a production line for recycling and recycling of steel slag and other resources based on the characteristics of steel slag hardness and rationally equipped equipment we provides customers with technical services and design of 30800tph steel slag processing line! Get PriceSteel slag crushing production line adopts jaw crusher for primary crushing, and uses hydraulic cone crusher for secondary and tertiary crushing, offering high crushing efficiency, low wear, energy saving and environmental protection, it has the features of high automation, low operation cost and reasonable allocation of equipmentSteel Slag Processing SHANGHAI SANME MINING MACHINERY Steel slag is a common industrial solid waste What kind of grinding mill is suitable for grinding steel slag powder? As a wellknown steel slag mill manufacturer in Guilin, China, HCMilling(Guilin Hongcheng) provides environmental protection vertical roller mill equipment for customers according to the market prospect of industrial solid waste recyclingSteel Slag Grinding Mill Manufacturer Professional Supplier

Steel slag recycling Great Wall Corporation

The steel slag vertical mill, independently designed and manufactured by Great Wall Machinery, is the special equipment for milling water slag, steel slag and other industrial slag into powder size It is the excellent equipment for producing steel slag powder in the processing Steel slag is the solid waste produced during the steel making process and about 100150kg steel slag is produced per ton of steel The utilization of steel slag is getting more and more attention in the world large processing capacity, high processing precision 3Low maintenance cost, more stable running Main equipment: 32×13m Steel slag grinding plant CHAENGThe company developed dry process and wet process techniques for steel slag recycling The technique with the capacity of 300,0002,000,000 t/a could be utilized by steel slag processing plant to reach integrated and high efficient use and zero emission, lead to recycling development of steel enterprises, ensure the high efficient and energy saving technique and equipment for the enterprisesIntroduction of integrated and efficient steel slag

UGMat Steel Slag Recycled Materials Resource Center

Steel Slag Asphalt Concrete INTRODUCTION Steel slag can be processed into a coarse or fine aggregate material for use in dense and opengraded hot mix asphalt concrete pavements, (1,2,3) and in cold mix or surface treatment applications (4) Proper processing of steel slag and special qualitycontrol procedures are extremely important in selecting steel slag for use in asphalt paving mixesStein provides Slag Processing and Steel Mill Services including Slag Handling, Scrap Handling, various Steel Mill Services, Sales of Aggregate Material and Construction EquipmentSteel Mill Services Construction EquipmentSteel slag i ntroduction: The steel slag crushing production line is a production line for recycling and recycling of steel slag and other resources based on the characteristics of steel slag hardness and rationally equipped equipment we provides customers with technical services and design of 30800tph steel slag processing line! Get Priceslag processing and applications

Scrap Processing Scrap Metal Services Steel Mill

Our range of services includes, but is not limited scrap yard management, finished or semifinished product services, melt shop services, logistics/transportation support, and slag processing Founded more than a decade ago, Scrap Metal Services is a leader in the industry, prioritizing recycling and environmental safety, and handling all ferromanganese, ferronickel, stainless steel dust processing, cobalt recovery from slag, lead zinc slag and carbon steel dust processing, ilmenite smelting and atmospheric magnesium production The participation in the application of Mintek’s technologies on a commercial basis has been a recentEAF Stainless Steel Dust Processing MINTEKSteel slag processing equipment recommended According to the characteristics of steel slag and the requirements of finished products, it can be processed by crushing and screening equipment, iron removal equipment and milling equipment, and processed to different particle sizes according to the requirements of use Tel:+8621 Steel slag processing equipment recommended Kefid

Slag Contractor – Slag Removal Construction Equipment

Slag Removal Stein utilizes slag pot haulers to remove slag from our customers' melt shops At the steelmakers request, we have direct furnace digging capabilities with enhanced frontend specialty loaders These specialty loaders are also used in digging the blast furnace pits at our integrated locationsThe steel slag vertical mill manufacturer has a LM vertical mill that can grind steel slag into powder, which can be divided into coal, cement, slag, and nonmetallic ore milling fields The finished product has a particle size of 22180μm and a production capacity of 5700t /H 1 Is it useful to grind steel slag into powder?What Mill Can Grind Steel Slag Into PowderSteel slag processing 2021 High Capacity 150 Tph Mobile Equipment configuration: vibrating feeder, jaw crusher, hydraulic cone crusher, vibrating screen, belt conveyor, iron remover (magnetic separator) Steel slag recycling benefits: Steel slag is solid waste generated during steel productionMainly composed of blast furnace slag, steel slag, ironcontaining dust (including iron oxide skin steel slag crushing conveyor kjchbrzeskopl