عنا

مرحبا هل يمكنني مساعدتك؟

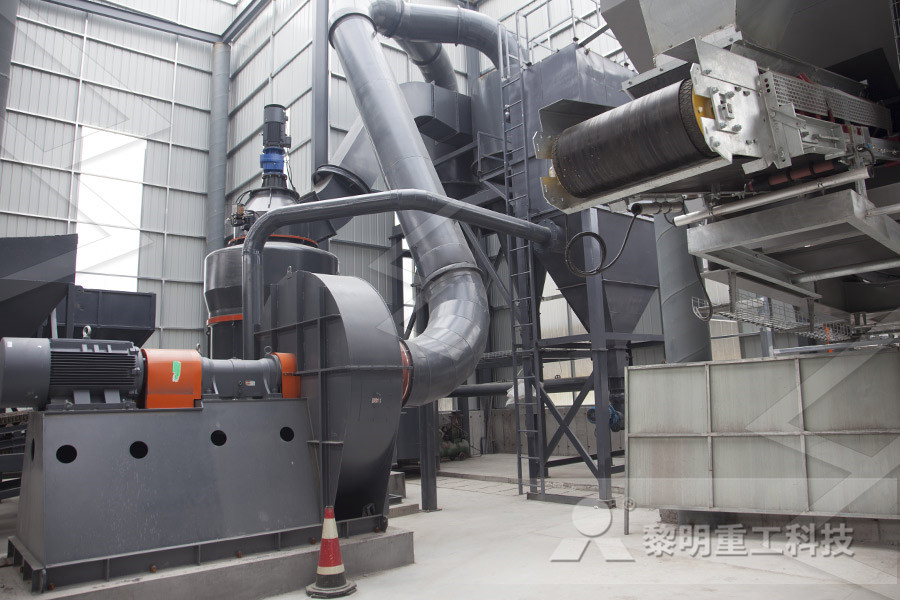

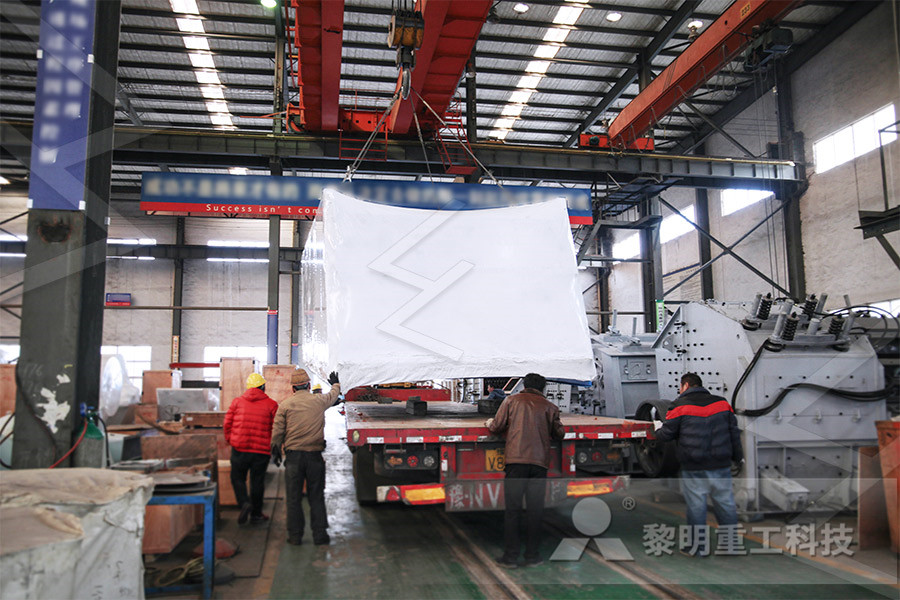

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

dry beneficiation of al a review dwari

2021-03-16T00:03:26+00:00

Dry Beneficiation of CoalA Review Request PDF

Beneficiation of coal is often imperative to improve the efficiency of coal utilization and reduce pollution Electrostatic beneficiation is an advanced dry fine coal cleaning technology to processDry beneficiation of coal: a review Dwari, Ranjan The wet beneficiation process for coal cleaning is currently the predominant method of purification of coal in the world However, dry beneficiation of coal has obvious advantages over wet processes The dry processes for coal are based on the physical properties of coal and its Dry beneficiation of coal : a reviewAug 21, 2014 Thus, dry coal beneficiation becomes the research hotpoints in the field of coal cleaning worldwide in recent years This paper systematically reviewed the promising research efforts on dry coal beneficiation reported in literature in last 5 years and discussed the progress in developments of dry coal beneficiation worldwideProgress in developments of dry coal beneficiation

Ranjan Dwari Academiaedu

dry beneficiation of coal—a review more by Ranjan Dwari Coal continues to play a major role in the economic development of a country, especially in metallurgical industries and conventional power generation plantsCOAL BENEFICIATION DRY METHODS Rick Honaker, University of Kentucky Gerald (Jerry) Luttrell, Virginia Tech USIndia 6th Coal Working Group Meeting L’Enfant Plaza Hotel Washington DC September 23, 2009Coal Beneficiation Dry Methods EnergygovJul 01, 2016 Dry beneficiation of fine coal of +150–500 μm in size was conducted using densitysegregation in a gas–solid fluidized bed without any separation mediaThe coal particles in a cylindrical column (inner diameter = 100 mm and bed height = 100 mm) were fluidized at a given air velocity u 0 /u mf = 13–30 for thirty minutes where u 0 and u mf are the superficial air velocity and the Dry beneficiation of fine coal using densitysegregation

DRY BENEFICIATION OF COAL—A REVIEW: Mineral Processing

May 07, 2007 The wet beneficiation process for coal cleaning is currently the predominant method of purification of coal in the world However, dry beneficiation of coal has obvious advantages over wet processes The dry processes for coal are based on the physical properties of coal dry beneficiation of coal—a review more by Ranjan Dwari Coal continues to play a major role in the economic development of a country, especially in metallurgical industries and conventional power generation plantsRanjan Dwari AcademiaeduMay 01, 2017 1 Introduction Water based wet separation processes are the main methods utilized in the field of coal beneficiation today These techniques are, however, unsuitable for coals that tend to slime in a wet separation process or for those coals located in arid or cold regions , During wet separation processes a lot of coal slime is generated and recoveredCharacteristics of fluidization and drybeneficiation of a

Dry beneficiation of fine coal using planar air jets

Jan 01, 2018 1 Introduction Coal plays a vital role in global energy mix In 2015, coal's share of global primary energy consumption is 292% Coal beneficiation can improve coal quality by removing the gangue minerals and is the most effective and economic method for clean processing of coal resources , , , In the last several decades, the yields of − 6 mm coal during coal mining increase This article examines the application of dry beneficiation technology to the separation of coal and mineral matter in a novel airfluidized bed The Reflux Classifier (RC) is an innovative design that incorporates an inclined zone above a conventional fluidized bed to achieve increased segregation rates and a higher throughput than separators The Effect of Vibration on Dry Coal Beneficiation in the Statistical optimization study of jigging process on beneficiation of fine size high ash Indian noncoking coal A Tripathy, L Panda, AK Sahoo, SK Biswal, RK Dwari, AK Sahu Advanced Powder Technology 27 (4), 12191224 , 2016Dr Ranjan Kumar Dwari Google Scholar

Technoeconomic impact of optimized lowgrade thermal coal

can therefore be exploited for considerable financial and utilization benefit References A substantial valueadding beneficiation option is DWARI, RK and RAO, KH 2007 Dry beneficiation of coal—a review Mineral identified from the Waterberg Upper Ecca modelJun 15, 2017 This report reviews a broad range of technical developments in coal beneficiation covering conventional, physical densemedia and dry coal treatment, upgrading technologies using thermal, chemical and biooxidation, coal blending, and applications for the use of ultrafine coal Coal beneficiation, CCC/278 IEA Clean Coal CentreThe dry separation methods for coal beneficiation have been regaining attention in the past decades A number of improved or newly designed devices have been developed—one of them is a negative pressure pneumatic separator (NPPS) The said method of separation is based on the differences in the physical properties between coal and gangue minerals, such as the grain density, size, and shapeModelling of Hard Coal Beneficiation Process Utilising

20 CHAPTER THIRTEEN REFERENCES RF1

Dwari, R K Rao, K Hanumantha (2007) 'DRY BENEFICIATION OF COAL— A REVIEW', Mineral Processing and Extractive Metallurgy Review, 28: 3, 177 — 234 22 Eberhard, A (2011) The Future Of South African Coal: Market, Investment, And Policy Challenges Freeman Spogli Institute for International Studies Working Paper#100, January 2011Dwari and Rao, 2007; Dwari and Rao, 2008) The first attempts at the dry beneficiation of fine pulverized coal (170 microns) in South Africa were undertaken by Bada et al (2010) using the triboelectrostatic separator In this review, a number of dry beneficiating techniques and their feasibilities are reviewed, followed by the presenThe potential of electrostatic separation in the J The Canadian Journal of Chemical Engineering, published by Wiley on behalf of The Canadian Society for Chemical Engineering, is the forum for publication of high quality original research articles, new theoretical interpretation or experimental findings and critical reviews in the science or industrial practice of chemical and biochemical processesCoal surface conditioning for electrostatic separation

Coal Beneficiation using an Air Dense Medium Fluidized Bed

The increasing consumer demands and greater environmental constraints compared with the past requires the need of coal beneficiation Coal beneficiation is a process to remove impurities including ash, sulfur and rock to update its value (He et al, 2016) The coalcleaning process could be classified into chemical cleaning and physical cleaningTo intensify the production of coal, mechanisation of coal mining is gradually increasing The process, being less selective, increases the quantity of shales, stones and other impurities in coal Dry methods of separation of these impurities may serve as a preconcentration step prior to wet processes of beneficiation Dry beneficiation will eliminate the energy intensive process of dewatering Dry beneficiation of coal: A review eprints@NMLTo intensify the production of coal, mechanisation of coal mining is gradually increasing The process, being less selective, increases the quantity of shales, stones and other impurities in coal Dry methods of separation of these impurities may serve as a preconcentration step prior to wet processes of beneficiation Dry beneficiation will eliminate the energy intensive process of dewatering Dry beneficiation of coal: A review eprints@NML

DRY BENEFICIATION AND CLEANING OF CHINESE HIGH

Dry beneficiation and cleaning of Chinese highash coarse coal 663 Dry coal beneficiation technology utilizing a densemedium gassolid fluidized bed has drawn worldwide attention and developed rapidly in the past few years It has the advantages of low investment cost, no wateruse, high separation efficiency, wideThis article examines the application of dry beneficiation technology to the separation of coal and mineral matter in a novel airfluidized bed The Reflux Classifier (RC) is an innovative design that incorporates an inclined zone above a conventional fluidized bed to achieve increased segregation rates and a higher throughput than separators The Effect of Vibration on Dry Coal Beneficiation in the Dwari, R K Rao, K Hanumantha (2007) 'DRY BENEFICIATION OF COAL— A REVIEW', Mineral Processing and Extractive Metallurgy Review, 28: 3, 177 — 234 22 Eberhard, A (2011) The Future Of South African Coal: Market, Investment, And Policy Challenges Freeman Spogli Institute for International Studies Working Paper#100, January 201120 CHAPTER THIRTEEN REFERENCES RF1

(PDF) Fine Coal Dry Cleaning using an Air Dense Medium

[6] RK Dwari, KH Rao, Dry beneficiation of coal A review, Mineral Processing and Extractive Metallurgy Review, 28 (2007) 177234 [7] Q Chen, L Wei, Coal dry beneficiation technology in china: the stateoftheart, China Particuology, 1 (2003) 5256The increased mechanization in the underground coalmining industry has increased the volume of fine size coal and waste (refuse) in the mined coal Processing of runofmine (ROM) coal is generally done using water away from mine and in some cases the coal has to be transported a long distance to the preparation plant Dry processing of coal can be economical as it will not utilize water and Beneficiation of Fine Coal Using the Air Table Addendum A: Performance report on the applicable dry coal processing techniques 1 NWU in association with CoalTech Dry processing for coal preparation: a review (a) N Hughes (b) Prof M Le Roux (c) Prof QP Campbell Utilizing dry coal beneficiation as opposed to the conventional wet methods arises for numerousDry processing for coal preparation: a review

Saimm aug by SAIMM Issuu

DWARI, RK and HANUMANTHA RAO K 2007 Dry beneficiation of coal – A Dry cleaning of coal: review, fundamentals and opportunities Dry beneficiation technology of coal with an air dense Jong, 2004; Dwari and Hanumantha Rao, 2007; Sahu et al, 2009; Mohanta et al, 2012) This process is not recognized as a wellestablished industrial practice because of the availability of efficient wet processing technology However, with the revival of interest in dry beneficiation of coal in general, and ADMFB in particular, there is a v115n8a13 Influence of medium particle size on the Research Expertise: Mineral processing, Beneficiation of low grade ore (Iron ore, Chromite ore, Graphite ore, Manganese ore etc), Utilization of plant tailings, slimes waste, Wet Dry beneficiation of coal, Surface chemistry Froth flotation of complex ore and coal, Equipment selection, Process flowsheet development OptimizationCSIR IMMT Mineral Processing People

Destoning the Moatize Coal Seam, Mozambique, by Dry Jigging

This paper proposes prebeneficiation studies by air jigs of the coal layers from a Moatize coal deposit Prebeneficiation, also called destoning, removes tailings before the beneficiation plant The air jigs operate in the same granulometric size range as the heavymedia cyclones (HMCs) that are installed in the preparation plant With the destoning, the heavymedia circuit operates with a Dry beneficiation of coal—a review RK Dwari, KH Rao Mineral Processing and Extractive Metallurgy Review 28 (3), 177234, 2007 153: 2007: Adsorption mechanism of mixed cationic/anionic collectors in feldsparquartz flotation system A Vidyadhar, KH Raok hanumantha rao Google Scholar Citations1 Statistical optimization study of jigging process on beneficiation of fine size high ash Indian noncoking coal, Alok Tripathy, Lopamudra Panda, AK Sahoo, SK Biswal, RK Dwari, AK Sahu, Advanced Powder Technology,2016, 27, pp 12191224 2 Preparation of Graphene Oxide by Dry Planetary Ball Milling Process from Natural GraphiteDr Ashok Kumar Sahu CSIR IMMT

Minerals Free FullText The Effect of the

Although compound dry separation technology has been applied to industrial applications for +6 mm size fraction of coal separation, the technology has not been widely applied in the separation of fine coal (−6 mm) In this study, the effect of the partition plate unit characteristics on both the average density of particles in the bed uniformly and the final separation results in a fine coal