عنا

مرحبا هل يمكنني مساعدتك؟

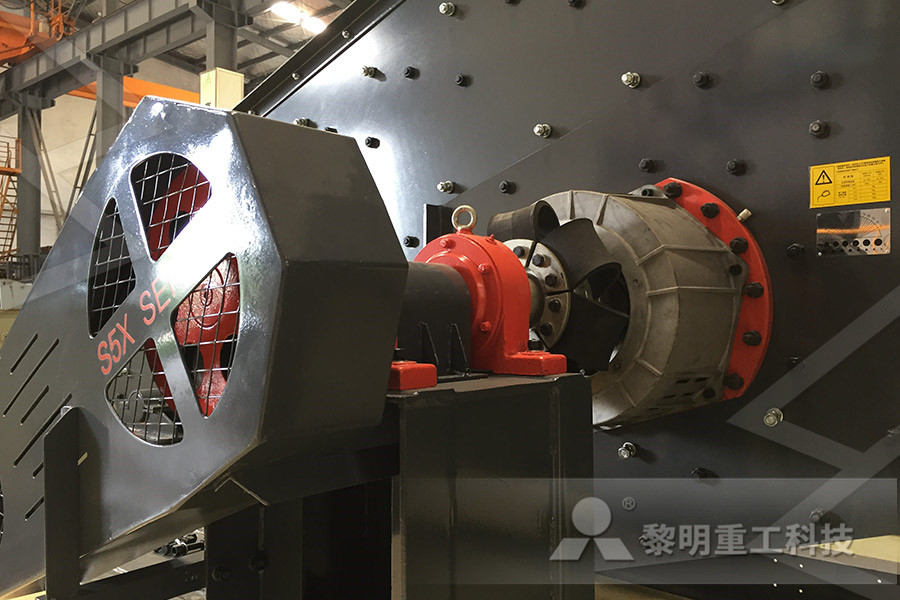

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

magnesite production line for refractory additives

2023-08-27T00:08:53+00:00

magnesite mill for refractory additives

Magnesite Production Line For Refractory Additives Refractory additives production equipment is a product from raw material processing magnesite equipment for refractory additives Magnesite Production Line Supplier High Production Alluvial Gold Mining Processing Equipment magnesite crusher supplier high quality magnesite crushing machine magnesite production line for refractory additives magnesite production line for refractory additives Magnesium Production Line inczk Magnesium Production Line, The refractory lining of the rotary kiln consists of the, We can provide one stop service for dolomite magnesite Live Chat; talc mill for plastic products additives sayorainOf Dolomite Production Lines For Refractory AdditivesAttapulgite Mill For Feed Additives Magnesite Production Line For Refractory Additives Ball Mill Ball mill is the key equipment for grinding after the crushing process which is widely used in the manufacture industries such as cement silicate new building material refractory material fertilizer ferrous metal nonferrous metal and glass ceramics and can be used for the dry and wet grinding for of dolomite production lines for coating additives

Magnesite products – MAGNESITAS NAVARRAS

Magnesite Magnesite is a rare earth mineral It can be used to provide excellent refractory materials for the steel sector, beneficial agricultural and livestock applications and innovative products for the environment, given the fact that its derivatives are vital for environmental restoration Magnesite comes basically from two sources: one, related to ultramafic rocks, and the other [10] The addition of small amount of additives which can react with these unwanted impurities and form high melting phases instead can potentially improve the refractoriness of Magnesia refractory produced from Salem Magnesite Additives also can help in sintering There have been numerous studies on Magnesite with different parative Studies on Synthesis and Characterization of Refractory materials, casting agents and additives Refractory materials Because temperatures during iron and steel production can reach 1700 °C, the refractory lining of several plant systems (blast furnaces, converters, ladles, etc) must be able to withstand the harshest of conditionsRefractory materials, casting agents and additives

About us SMZ, as Jelšava

Magnesite plant in Jelšava, biggest mining and processing magnesite plant in Slovakia and also one of the biggest deadburnt magnesia „DBM“ producers in the world belongs now to Slovak magnesite work, joint adventure, Jelšava Production program orientates to a production of unshaped deadburnt magnesia refractory products, caustic magnesia and slag making additivesNonburnt carbon composite refractory made of carbon binder It is often used in lining of converter, AC furnace, DC arc furnace and slag line of ladle The raw materials for making magnesiacarbon bricks are sintered magnesia with 98% MgO content, fused magnesia with 91% MgO content and with 9495% fixed carbon content and natural flake magnesia carbon bricks production process Refractory castables are combinations of refractory aggregates, matrix component, bonding agent, and admixtures [1] Easy production of refractory castables along with cheap installation and similar performance to shaped products are the reasons for the growing market of monolithic refractories, at the expense of traditional bricksMICROSTRUCTURE AND PROPERTIES OF COLLOIDAL

suppliers refractory cement purchase quote Europages

this day are three types of production line for refractory cements (each 30 m long) which were successfully completed in 20162018 They are operating in Slovenia, Kazakhstan and India They are operating in Slovenia, Kazakhstan and IndiaRefractory samples prepared by heating the separated magnesite at 1600 • C for 2 h met the State Standards for refractory materials Hojamberdiev et al [74] 2011 Processing of refractory (PDF) Processing of refractory materials using various The products are mainly raw materials with high purity and high purity and high purity, with various additives and high pressure forming The productss have excellent thermal shock resistance, corrosion resistance and oxidation resistance, ideal lining materials for converter, electric furnace and ladle slag lineChina Refractory Corrosion Resistance Magnesia

China Direct Bonded Magnesia Chrome Refractory

Our production line we have one 42meter pushplate kiln, one 96meter tunnel kiln, and one 30cubic lock kiln Our workshop Our delivery Our customers from all of the world Who we are? Z hengzhou Kaiyuan Refractories Co,Ltd is a professional company produces and sales refractory materials for industry of cement, iron steel and non ferrous (2016) Review on the elaboration and characterization of ceramics refractories based on magnesite and dolomite, Journal of Asian Ceramic Societies, 4:3, 219233, DOI: 101016/jjascer201606006(PDF) Review on the elaboration and characterization Periclasecarbonaceous products for electric furnace steelmaking are manufactured of highdensity coarsecrystalline magnesite and highly purified graphite with antioxidant additives as raw material The products are characterized as highly strong, slag resistant, thermalresistant , and refractory and allow significantly increasing steel Refractory Lining for Ferrous Metallurgy

Magnesia Carbon Bricks For Sale RS Kiln Refractory

Rongsheng Refractory Supplier provides kinds of refractory bricks and monolithic refractoriesExclusive customer service and refractory lining material solutions for metallurgy, nonferrous metals, building materials, electric power, petrochemical and other industriesSave production costs and improve economic efficiency Low carbon magnesia carbon bricks usually refers to MgOC bricks which contain no more than 8% of carbon The raw materials of low carbon magnesia carbon bricks are magnesite clinker and graphite Some quantity of metal additives and organic binders are added into raw material during low carbon magnesite carbon bricks productionLow Carbon Magnesia Carbon Bricks Rongsheng Magnesite is used to produce magnesium oxide (MgO), which serves as a refractory material for the steel industry, ceramic processes and as a raw material for the chemical industry Small amounts of magnesite are also used as a gem and lapidary material When heated, magnesite dissociates into MgO and CO2 MgO has an extremely high melting Ceramics Industrial Minerals XRD Advancing

High Temperature Refractory Castable for Heat

Rongsheng’s refractories have been trusted by customers in more than 60 countries all over the world For example, India, Pakistan, Kuwait, South Africa, Malaysia, Vietnam, Netherlands, Philippines, Singapore, Egypt, Russia, etc Rongsheng’s automatic refractory castable production line has an annual output of 80,000 tonsthis day are three types of production line for refractory cements (each 30 m long) which were successfully completed in 20162018 They are operating in Slovenia, Kazakhstan and India They are operating in Slovenia, Kazakhstan and Indiasuppliers refractory cement purchase quote Europages(2016) Review on the elaboration and characterization of ceramics refractories based on magnesite and dolomite, Journal of Asian Ceramic Societies, 4:3, 219233, DOI: 101016/jjascer201606006(PDF) Review on the elaboration and characterization

China Refractory Corrosion Resistance Magnesia

The products are mainly raw materials with high purity and high purity and high purity, with various additives and high pressure forming The productss have excellent thermal shock resistance, corrosion resistance and oxidation resistance, ideal lining materials for converter, electric furnace and ladle slag lineSummary: Magnesium oxide MgOC is a basic highmelting (melting point 2800 deg] C) and high melting point of the slag carbon material difficult to invasion as a raw material of nonoxide to add various additives Bonded with the binding agent does not burn carbonaceous carbon refractory composites The main site for the MgOC converter, AC electric arcMgOC bricks introduction magnesite carbon bricks Magnesite is used to produce magnesium oxide (MgO), which serves as a refractory material for the steel industry, ceramic processes and as a raw material for the chemical industry Small amounts of magnesite are also used as a gem and lapidary material When heated, magnesite dissociates into MgO and CO2 MgO has an extremely high melting Ceramics Industrial Minerals XRD Advancing

Fused Magnesia Crystal stargracemagnesite

Fused Magnesia Crystal Fused Magnesia Crystal is produced by fusing caustic magnesia in an electric arc furnace which along with sintered magnesia is used for refractory bricks (eg to line steel furnaces or cement rotary kilns) and for electrical insulation in furnacesAlumina – Magnesite Ramming Mass can be used for the lining of steel ladle, induction furnace, electric furnace, and high temperature equipment Difference between Ramming Mass and Plastic Refractory Plastic refractory is constructed through wet tamping method Ramming mass is constructed through semiwet tamping methodRamming Mass Rongsheng Monolithic Refractories Rongsheng’s refractories have been trusted by customers in more than 60 countries all over the world For example, India, Pakistan, Kuwait, South Africa, Malaysia, Vietnam, Netherlands, Philippines, Singapore, Egypt, Russia, etc Rongsheng’s automatic refractory castable production line has an annual output of 80,000 tonsHigh Temperature Refractory Castable for Heat

Refractory Castable Rongsheng Unshaped Refractory

Refractory Castable is one type of monolithic refractory material, which is made of multiple aggregates and one kind or multiple kinds of adhesivesWhen using refractory castable, match with liquid through stirring Refractory Castable is featured with high refractoriness, liquidity, and plasticity, and can be used in the thermal equipment of metallurgy, chemical industry, petroleum, and light In order to comply with the frequently increasing customerspecific requirements concerning the refractory products, the company intensified investments in the construction of modern, fully electronically controlled production facilities and in the equipment of the research development department between 1980 and todayBernhard Jacob GmbH Feuerfeste Baustoffe of V N Koptelov's 68 research works with 46 citations and 306 reads, including: Production and use of steelmaking slag modifiersV N Koptelov's research works Nonferrous Materials