عنا

مرحبا هل يمكنني مساعدتك؟

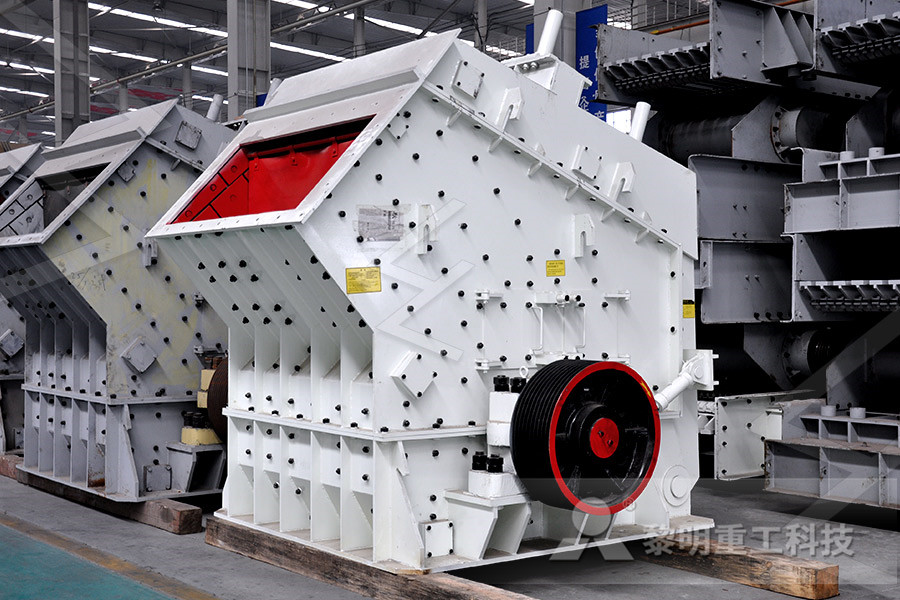

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

hard rock crusher classification.html

2019-05-09T16:05:41+00:00

Types of Rock Crushers Quarry Crushing Equipment Kemper

Apr 22, 2020 Impact Crushers – VSIs and HSIs Impactstyle crushers include VSIs, as well as horizontal shaft impactors (HSIs), and are best used with less abrasive rock types, like limestone These types of machines break apart material by the impacting forces of certain wear parts known as blow bars and impact plates or toggles Some operations also use impactstyle crushers after they have hardrock version of the singletoggle jaw crusher are based on hard feed material that is difficult to crush 90 120 150 200 230 270 300 1 10 100 1,000 Mesh size [mm] 100 90 80 70 60 50 40 30 20 10 0 CSS jaw opening [mm] Passage [wt%] Typical grain size distribution of the crushed product 100 150 200 250 300 350 400 1,600 1,400 1,200 1,000 800 Industrial Solutions Jaw crushers ThyssenKruppRock crushers have a wide range of suitable material to choose from, whether it’s soft or hard, or even very hard, rock crushers can reduce those large rocks into smaller rocks, gravel, or even rock dust Here are some typical materials that break or compress by industry crushers, such as Granite, quartz stone, river pebble, limestone Rock Crusher Eastman Rock Crusher

Crusher Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedJan 14, 2021 There are different types of stone crushers in mining industry such as jaw crusher, cone crusher, impact crusher, and sand making machine This article will tell you how to maintain the 4 types of rock crushers and how to efficicently improve their performance How to make your crushers efficiency4 Types of Stone Crushers' Maintenance and Efficient The Hardrock Crusher is a One Piece Alloy wheel that will give your vehicle the look and performance you've been searching for These stunning Multi spoke wheels will definitely transform your ride into something truly special! 20x10 20x12 20x9 Black Black Milled View More Options SortHardrock Crusher Wheels for Sale All Sizes Colors

Hardrock Crusher 20x12 44 Black Milled H704

These Hardrock Crusher wheels feature a Black Milled finish and are sure to make your ride stand out! This particular wheel setup is in 20x12 with a 44 offset The Hardrock Crusher is a One Piece Alloy wheel that features hidden lugs These beautiful Multi spoke wheels are available in a 6x135 configuration and will be sure to elevate the look of your vehicle build!The average miner can instead purchase a CrazyCrusher manual rock crusher or an electric or gas powered rock crusher and get the gold out in smaller batches Crushing rock to recover gold can be easier, faster, and much more profitable than prospecting in overworked streams and riversRock Crushers Gold Prospecting Mining Equipment In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surface Less abrasive and softer rocks or stones Crushing in Mineral Processing

Portable Rock Crushers Patriot mining and equipment

My crushers not only destroy Rock they can also grind glass, bones or any other hard substance except metal Introducing the new 5th generation 13 inch Belt drive Rock Crusher Quick change screen, wheel mounted, $1,095 Predator engine Contact me for more details Pictured belowhardrock version of the singletoggle jaw crusher are based on hard feed material that is difficult to crush 90 120 150 200 230 270 300 1 10 100 1,000 Mesh size [mm] 100 90 80 70 60 50 40 30 20 10 0 CSS jaw opening [mm] Passage [wt%] Typical grain size distribution of the crushed product 100 150 200 250 300 350 400 1,600 1,400 1,200 1,000 800 Industrial Solutions Jaw crushers ThyssenKruppA crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher Wikipedia

4 Types of Stone Crushers' Maintenance and Efficient

Jan 14, 2021 The cone crusher in the secondary or tertiary crushing proccess often fractures mediumhard or hard rocks like pebble, quartz, granite, etc It is easy to get premature crusher failure, if operators cannot make a correct and timely inspection and maintenance 6 Tips to help you prolong the concrusher's service life:Crushers The size requirement of the primary rock crusher is a function of grizzly openings, ore chute configuration, required throughput, ore moisture, and other factors Usually, primary crushers are sized by the ability to accept the largest expected ore fragmentRock Crushers 911MetallurgistThe average miner can instead purchase a CrazyCrusher manual rock crusher or an electric or gas powered rock crusher and get the gold out in smaller batches Crushing rock to recover gold can be easier, faster, and much more profitable than prospecting in overworked streams and riversRock Crushers Gold Prospecting Mining Equipment

Large Scale Hard Rock Crusher Plant — Appropriate Process

The hard rock crusher solution! We developed the JCRD hard rock crusher plant specifically for crushing stone and gravity recovery of minerals in clean, hard rock ore bodies The plant uses a 2stage Jaw Crushing and RD Wet Impactor crushing circuit, followed by the required concentration modules such as a Knelson or Spirals circuit350400TPH Hard Rock Crusher Plant Production capacity from 350TPH 400 TPH stone crusher plant for hard rocks, stones, minerals This 350400TPH hard rock crushing plant is widely used as sand making line, rock crushing line, ore dressing line, aggregate production line, construction waste recycling plant and so on350400TPH Hard Rock Crusher Plant uni CS CS cone crusher is of low costs, high crushing capacity, low energy consumption, compact structure etc In the 80TPH 120TPH Hard Rock Crusher Plant, B series VSI crusher is a kind updated Barmac VSI crusher VSI crusher is widely used to produce high quality sand and aggregate which will be used as building and construction aggregate80TPH 120TPH Hard Rock Crusher Plant uni

VSI Crushers REMco

REMco ST/AR VSI crushers are rockonanvil vertical shaft crushing machines designed to operate as second, third or fourth stage crushers for processing soft to medium/hard rocks, ores or minerals that contain less than 15% abrasives (silica, alumina, and iron) Maximum feed size is 6” (150 mm) and product sizes can be from 1 1/2” (40 mm My crushers not only destroy Rock they can also grind glass, bones or any other hard substance except metal Introducing the new 5th generation 13 inch Belt drive Rock Crusher Quick change screen, wheel mounted, $1,095 Predator engine Contact me for more details Pictured belowPortable Rock Crushers Patriot mining and equipmentLokotrack® LT106™ is equipped with ® C106™ jaw crushing unit, especially designed for crushing hard rock types such as granite, basalt and gneiss The CAT® engine with hydraulic drive ensures troublefree operation The hydraulic drive enables the crusher direction to be changed in the event of blockage to clear the cavityLokotrack® LT106™ mobile jaw crusher Outotec

China Stone Impact Crusher, Stone Impact Crusher

China Stone Impact Crusher manufacturers Select 2021 high quality Stone Impact Crusher products in best price from certified Chinese Impact Crusher manufacturers, Mining Equipment suppliers, wholesalers and factory on MadeinChinaWe have jaw crushers, impact crushers, cone crushers, sand makers and so on They can meet various production needs through free combinations Jaw Crusher This is a complete hard rock crushing line whose capacity is around 450500TPH For more configurations, please click here Read More (800TH1000TH) Mediumhard Rock Crusher, Grinding Mills, Crushing and Grinding Equipment The Sandvik range of rock support drill rigs is designed for a wide array of hardrock mining operations, tunneling and civil engineering applications Thanks to onboard cement mixers, cement bag platforms, and optional cement silos and steel strand reels, the rigs can operate autonomously for Mining Equipment, Breaking, Drilling Crushing Products

Industrial Solutions Jaw crushers ThyssenKrupp

hardrock version of the singletoggle jaw crusher are based on hard feed material that is difficult to crush 90 120 150 200 230 270 300 1 10 100 1,000 Mesh size [mm] 100 90 80 70 60 50 40 30 20 10 0 CSS jaw opening [mm] Passage [wt%] Typical grain size distribution of the crushed product 100 150 200 250 300 350 400 1,600 1,400 1,200 1,000 800 The hard rock impact crusher RHSMK/HCI stands for excellent material reduction and efficient operation It is designed for applications with hard and tough rock and offers high operational reliability Capacity range is between 130 450 t/h In comparison to other impact crushers – especially with hard materials – longer working life is HARD ROCK IMPACT CRUSHER Mineral Processing GmbH Willpactor II Rock Crushers The Willpactor II® handles feed sizes beyond the range of conventional secondary and tertiary crushers A large feed opening, contoured hichrome rotor, and easy maintenance are just a few of the features that make the Willpactor II® impact rock crusher machine a great asset for any rock crushing applicationRock Stone Crushers Rock Crushing Machines Williams

Cone Crusher 1000SR

1000SR Cone Crusher Hard Rock Related Products 1150 Maxtrak Prescreen The ® 1150 Maxtrak PreScreen is a high performance, medium sized track mobile rock crusher with an independent prescreening system At the heart of the Maxtrak is the Automax® cone crusher with hydJaw Crushers McLanahan’s Universal Jaw Crusher was first patented in the United States as an overhead eccentric, singletoggle jaw crusher in 1906 It has since earned a reputation as a hard rock crusher and is suitable for the toughest, most abrasive material including granites and basaltsMcLanahan’s Extensive Crusher Line Hub4® MP Series™ cone crushers are known for having the highest crushing force of any cone crushers similar in size Suitable for reducing and shaping both hard rock and soft rock, these crushers are designed especially for mining applications® MP Series™ cone crushers Outotec

Impact Crusher Rock Crusher Machine Manufacturer JXSC Mine

The impact crusher is widely used for sand and rock fine crushing in the industry of roads, railways, reservoir, electricity power and building materials and so on And the compressive strength less than 350 MPa 3 Working Principle Jaw rock crusher does cyclical movement by swinging jaw to crusher rockJaw Crushers exert more crushing power and are the best choice for very hard rock like granite and abrasive rock Secondary Crusher A secondary crusher is one that takes crushed material out of a primary crusher and reduces the product further An impactor or a cone crusher can be used as a secondary crusher (68” feed size to ½” to 2 Portable Crushing Equipment Sales and Rental Thompson In depth review of a rock crush that I use on episode 2 and consistently use in the field and home For more info watch the review and to see it in action sNuggets Review of the KM Rock Crusher YouTube

Impact Crushers Port Quarry Supplies Ltd

GOODWIN BARSBY 5570 HRC 'Hard Rock Cuber' Fixed Hammer Impact Crusher GOODWIN BARSBY 5570 HRC 'Hard Rock Cuber' Fixed More Information » APK 60 Impact Crusher APK 60 Fixed Hammer Impact Crusher HolmesHazemag More Information »Global Mining Equipment (GME) provides gold mining equipment that has been designed and built by miners for miners Rigorous field testing in various countries and climates allows us to tailor designs and specifications for the small (1 ton per hour) to medium scale operations (10+ tons per hour)Global Mining Equipment HOMEA cone crusher breaks rock by squeezing the rock betwe en an eccentrically gyrating spindle, which is cov ered by a wear resistant mantle, and the enclosing concave hopper, covered by a mang anese (PDF) SIZE REDUCTION BY CRUSHING METHODS

Pe=250400 Mobile Hard Rock Jaw Crusher 500 Tph Crusher

bearing jaw crusher pe 400 x 600 Hard Rock Crusher Hard Rock Crusher Primary Menu 600 700 tph 400 500 tph 250 300 tph mobile jaw crusher pe 400 x 600 Portable jaw crushers are most commonly used as primary crushers They are suitable for processing hard rock, soft rock and recycled materials Portable cone crushers are developed especially for secondary, tertiary and fine crushing with high productivity Portable cone crushers can reduce any rock types Global expertise, local supportNW Series™ portable crushers Outotec