عنا

مرحبا هل يمكنني مساعدتك؟

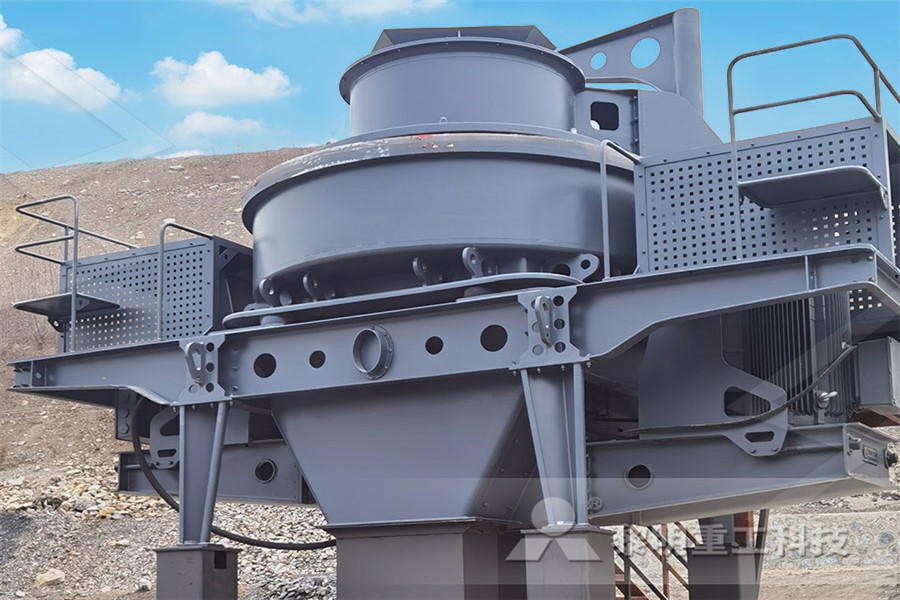

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

extraction of pper flowchart

2022-03-02T02:03:03+00:00

Flowchart of Extraction of Copper by Maddie Clancy

Flowchart of Extraction of Copper from Chalcopyrite Ores Sulphur dioxide Gas The chemical compund with the formula SO2 Iron Silicate Slag, which is removed Sulphuric acid Copper Sulphide A mixture of metal oxides and silicon dioxide A strong mineral Flowchart of extraction of copper Zoom in on your browser to have a better view of our flowchart NonSulphate Ores Chalcopyrite Ores Powered by Create your own unique website with customizable templatesFlowchart of Extraction of Copper CopperCopper Mining Extraction Process Flow Chart This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral (ore)Copper Mining Extraction Process Flow Chart Process

flow chart of extraction of copper

Copper Mining Extraction Process Flow Chart,This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral ore Having a quick look now at how porphyry ores are treated and Copper Mining and Extraction: Oxide Ores The process used to treat sulfide copper ores begins at the mine site, where the copperbearing minerals are physically separated from the rest of the rock The flow diagram below shows how the percentage of copper increases as the ore is refined, first physically by froth flotation, then chemically by smelting and finally electrolytic refiningFlow diagram copper extraction process Manufacturer Of A simplified schematic drawing of copper flotation flowsheet Runofmine open pit ore will be crushed in a gyratory crusher The crushed ore will be processed by means of semiautogenous and ball mill grinding followed by rougher flotation, regrind, cleaner flotation, and dewatering to produce copper concentrate The concentrate will be trucked via the existing road network in the area to a Copper Process Flowsheet Example

Mining Flow Chart On Copper Extraction

Flow Chart For Copper Mining, Flow diagrams copper extraction part of an interactive online booklet about copper mining showing the basic steps in mining and purifying copper the flow chart shows you how copper is chat now create a flow diagram showing the main processes get price Mining Flow Chart On Copper ExtractionThe Kinsevere Copper Extraction Plant described in this report is a brownfield site located in southern part of the Katanga Province in the Democratic Republic of the Congo (DRC), approximately 20km north of the provincial capital, LubumbashiAN INTRODUCTION TO COPPER EXTRACTIONFlowchart of extraction of copper Zoom in on your browser to have a better view of our flowchart NonSulphate Ores Chalcopyrite Ores Powered by Create your own Flowchart of Extraction of Copper Copper

flow chart of extraction of copper

Copper Mining Extraction Process Flow Chart,This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper Copper Mining and Extraction: Oxide Ores The process used to treat sulfide copper ores begins at the mine site, where the copperbearing minerals are physically separated from the rest of the rock The flow diagram below shows how the percentage of copper Flow diagram copper extraction process Manufacturer Of copper mine to mill flow chart jvk fotografie nl Copper mining extraction process flow chart this flowchart made of machinery icons explains or expresses in simple but clear terms the step of the copper mining and copper extraction process starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper flow chart of procedure of copper extraction

Flowsheet development in the context of copper extraction

Jul 04, 2013 FLOWSHEET DEVELOPMENT IN THE CONTEXT OF COPPER EXTRACTION sargonau Energy use in copper production ~100 GJ/tonne cathode copper 20% in mining SX/EW Flow Chart Click on image above to view full size Conclusion The SX/EW process has provided the copper industry with a tool that makes the extraction of copper from its ores How Hydrometallurgy and the SX/EW Process Made Copper The percentage of copper in the actual ore is too low for direct extraction of copper to be viable The concentration of ore is required and it is done by the Froth Flotation method Concentration of Ore: Extraction Of Copper Mining, Concentration, Smelting

copper extraction and purification chemguide

This page looks at the extraction of copper from its ores, its purification by electrolysis, and some of its uses Before you get too bogged down in the extraction of copper, make sure that you need it for whatever syllabus you are using Extracting copper from its ores The method used to extract copper The effect of extractant concentration on copper extraction was studied by contacting sulphate solutions containing 01M copper(II) at an initial pH value of 395 with LIX® 984N at concentrations from 5–25% (v/v) As shown in Figure 3, copper extraction Liquidliquid extraction and separation of copper(II) and copper extraction, then it is preferable to adjust the organic flow rather than change the organic concentration Increasing the extractant concentration incurs significantPractical Aspects of Copper Solvent ResearchGate

flowchart of the mining of an ore and the extraction of metal

copper mining and processing flowchart MORE DETAILS: copper mining and processing flowchart Place these products in the extraction process in ascending order of copper content Use the flow chart as a guide Matte Ore Cathode copper Blister Anode copper Copper concentrate Fire refined copper Extraction of Copper The chief and important ore of copper from which the metal is most isolated is copper pyrites (CuFeS 2) Froth floatation process is used for concentrating the ore The powdered Extraction of Copper and Aluminium – Study Material for The electrolyte is copper sulphate (CuSO4) mixed with a little amount of H2SO4 to increase the electrical conductivity Optimum potential difference is 13 volt for this electrolytic process During electrolysis, pure copper METALLURGY OF COPPEREXTRACTION OF COPPERBLISTER COPPER

Chapter 6 Copper Production Technology

shows flowsheets for pyrometallurgical’ and hydrometallurgical 2 copper production Tables 61 and 62 provide capsule summaries of these processes 1 PyrometaIIurgy IS the extractIon of metaI from Flowchart of extraction of copper Zoom in on your browser to have a better view of our flowchart NonSulphate Ores Chalcopyrite Ores Powered by Create your own unique website with customizable templatesFlowchart of Extraction of Copper CopperCopper Mining and Extraction: Oxide Ores The process used to treat sulfide copper ores begins at the mine site, where the copperbearing minerals are physically separated from the rest of the rock The flow diagram below shows how the percentage of copper increases as the ore is refined, first physically by froth flotation, then chemically by smelting and finally electrolytic refiningFlow diagram copper extraction process Manufacturer Of

flow chart of procedure of copper extraction

copper mine to mill flow chart jvk fotografie nl Copper mining extraction process flow chart this flowchart made of machinery icons explains or expresses in simple but clear terms the step of the copper mining and copper extraction process starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral oreThis page looks at the extraction of copper from its ores, its purification by electrolysis, and some of its uses Before you get too bogged down in the extraction of copper, make sure that you need it for whatever syllabus you are using Extracting copper from its ores The method used to extract copper from its ores depends on the nature of copper extraction and purification chemguideAug 21, 2020 Extracting of Copper from Other Ores Copper can be extracted from nonsulfide ores by a different process involving three separate stages: Reaction of the ore (over quite a long time and on a huge scale) with a dilute acid such as dilute sulfuric acid to produce a very dilute copperThe Extraction of Copper Chemistry LibreTexts

Chapter 6 Copper Production Technology

shows flowsheets for pyrometallurgical’ and hydrometallurgical 2 copper production Tables 61 and 62 provide capsule summaries of these processes 1 PyrometaIIurgy IS the extractIon of metaI from ores anD concentrates using chemical reactions at high temperatures 2 Hydrometallurgy is the recovery of metaIs from ores using waterbased The effect of extractant concentration on copper extraction was studied by contacting sulphate solutions containing 01M copper(II) at an initial pH value of 395 with LIX® 984N at concentrations from 5–25% (v/v) As shown in Figure 3, copper extraction increases from 28 g/L (44%) to 627 g/LLiquidliquid extraction and separation of copper(II) and copper extraction, then it is preferable to adjust the organic flow rather than change the organic concentration Increasing the extractant concentration incurs significantPractical Aspects of Copper Solvent ResearchGate

Evaluation of Copper SolventExtraction Circuit Data and

Evaluation of Copper SolventExtraction Circuit Data and Performance NB du Preez1* and JJ Taute2 1CM Solutions, Johannesburg, South Africa 2BASFSA Pty Ltd, Johannesburg, South Africa *Corresponding author: A wellperforming solventextraction circuit is a key part of producing good quality copper cathodeGiven below are the steps for extraction of copper from its ore Write the reaction involved (a) Roasting of copper (I) sulphide (b) Reduction of copper (I) oxide with copper given below are the steps for extraction of copper from Extraction of Cu +2 from dilute aqueous solutions as a case study by liquid cation exchanger in a modified rotating disc extractor was studied The liquid cation exchanger consisted of naphthenic acid dissolved in an inert carrier kerosene Variables studied were: initial concentration of Cu +2, disc rotational speed, concentration of naphthenic acid, flow rates of continuous and dispersed Extraction of heavy metals from aqueous solutions in a

Control of an industrial copper solvent extraction process

Jan 01, 2009 The studied copper solvent extraction process consists of four units, three for extraction and one for stripping, as presented in Fig 2The inputs of the process are pregnant leach solution series and parallel flow rates, F(PLSS) and F(PLSP), pregnant leach solution copper concentration, c(PLS), lean electrolyte flow rate, F(LE), lean electrolyte copper concentration, c(LE), and the flow rate Jun 28, 2017 Most current copper extraction processes burn sulfide minerals in air, which produces sulfur dioxide, a harmful air pollutant that has to be captured and reprocessed, but the new method produces elemental sulfur, which can be safely reused, for example, in fertilizers The researchers also used electrolysis to produce rhenium and molybdenum A new way of extracting copper MIT News Massachusetts Oct 06, 2020 Finally, by describing the studies on copper extraction from the resulting pregnant solutions, the applicable extraction agents have been reviewed Flow sheet of Kennecott plant Flow (PDF) Ammonia Leaching: A New Approach of Copper Industry