عنا

مرحبا هل يمكنني مساعدتك؟

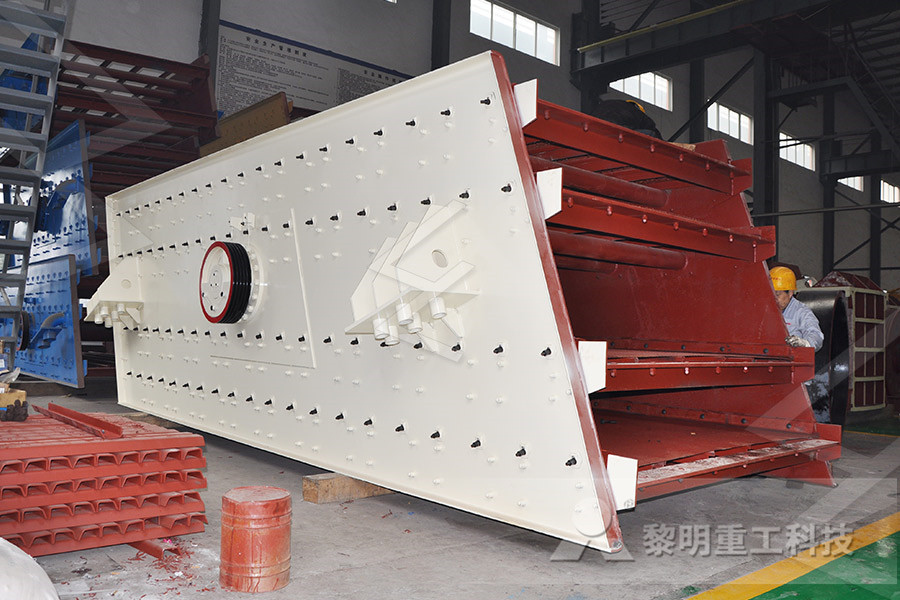

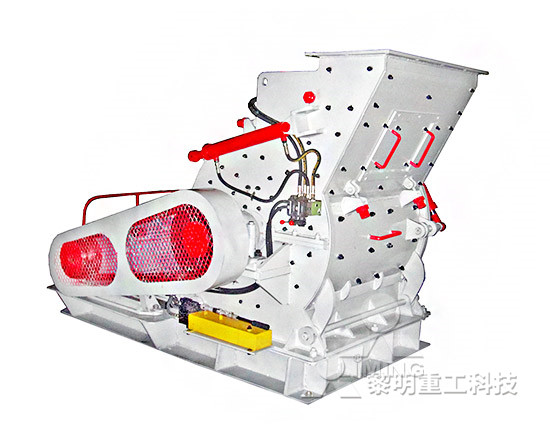

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

crusher machine maintenance

2023-03-01T12:03:18+00:00

Tips for Crusher Maintenance Thomasnet

Best Practices for Crusher Maintenance Regular maintenance is critical when it comes to the safe and effective operation of any milling or crushing machine These machines endure enormous amounts of stress for extremely long periods of Preventive means that by making regular checklist and inspections to keep crushers in good condition Maintenance checklist is usually set up on a daily (8 hours), weekly (40 hours), monthly (200 hours), yearly (2,000 hours) Only doing that, can you prolong the machine's life span and maximize its value in crushing process4 Types of Stone Crushers' Maintenance and Efficient The correct maintenance method is regular inspections and lubrication of the knives Once the knives are not sharp enough or damaged, they must be replaced as soon as possible The above are two points that need to be paid attention to in the maintenance of the plastic crusherMaintenance of Plastic Crusher Machine aumax

The Most Practical Jaw Crusher Repair and

The lubrication of the interface between the parts of the jaw crusher is very important It can minimize the friction generated during the operation, make the whole jaw crusher run smoothly, and extend its service life Unlike gyratory crushers, the main The jaw crusher should check the bearing temperature in time for normal operation If abnormal temperature occurs, there may be too much or insufficient grease, dirty grease or bearing damage; check the amount of grease or replace the grease and bearings jaw crusher maintenanceAnalysis of daily maintenance and maintenance crusher for another pass through the machine Efficiency of a multiple stage crushing plant can be maximized by operating a primary crusher at a setting which produces a satisfactory feed size for the secondary crusher and operating the secondary crusher (or the last stage crusher) in a closed circuit Glossary of TermsConstruction, Working and Maintenance of Crushers for

Regular crusher maintenance integral to reliability

Performing regular maintenance on crushers is integral to the reliability, performance and output they achieve Prevention is better than cure; by carrying out regular inspections operators will ensure their crusher runs for a longer period of time Maintenance of Jaw crusher Shut down the jaw crusher regularly and check the machine Check the interior parts wear condition at regular intervals, such as feeder pipe, impeller, circular guard plate, wearresistant block, etc Replace or repair wear parts on time Periodic inspection of the drive Maintenance and Repair of Jaw Crusher JXSC Mine Maintenance of Hydraulic System of Cone Crusher (2) When the temperature is high, the crusher machine can't run continuously for too long The crusher usually has a continuous working time of 4 hours under the condition that the temperature is higher than 30 °C (6) When the temperature is below 10 °C, the crusher should operate the Maintenance of Hydraulic System of Cone Crusher (2

Maintenance of Plastic Crusher Machine aumax

Maintenance of Plastic Crusher Machine Sep 27, 2020 With the development of industry and population increase, the amount of plastic products is increasing Waste plastic recycling has become a hot industry Plastic crushers are important equipment for recycling of waste plastics, attracting more and more people's investment Many customers Best Practices for Crusher Maintenance Regular maintenance is critical when it comes to the safe and effective operation of any milling or crushing machine These machines endure enormous amounts of stress for extremely long periods of time, relentlessly crushing incredibly hard materials down to Tips for Crusher Maintenance ThomasnetSometimes, impact crusher (sand making machine) equipment is required according to the process requirements Where, in the stone production line, most of the maintenance work of the equipment is for the maintenance work of the crusher equipment Doing this part of the work will make the maintenance work of the stone production line smoothly Crusher equipment maintenance Hongsheng

Avoid Unplanned Downtime: 5 Crusher Maintenance

Preventative maintenance is often viewed as unnecessary but minimizes downtime because the machine is getting repaired before failure Predictive means using historical service life data to determine when a machine will likely breakdown and then taking the necessary steps Before the maintenance of jaw crusher machine, all electrical control devices and electric motors should be power outages, locked, and posted with maintenance of identity When the equipment operation, not to carry out lubrication, cleaning, repair or maintenance work Jaw Crusher Maintenance Dragon Machinery Maintenance plays an important role in the whole operation Maintaining the crusher machine rationally can maximize the working efficiency, and here are the maintenance tips of the main parts Concave During the crushing process, there is a great impact on the concave which makes the filled zinc layer be out of shapeCone Crusher Tips of Operation and Regular

Jaw crusher maintenance : Pit Quarry

“Successful jaw crusher maintenance requires the right resources, the right tools and the right approach,” says Bill Macini, a Telsmith service technician Certainly when an operation is down, whether for preventive maintenance or component failure, there is always the pressure to get the plant up and running as soon as possibleHome » Crusher Service Genuine Service Solutions CMS Cepcor® are accepted as the leading multibrand crusher service provider, from routine maintenance to full crusher rebuilds, we have a costeffective solution for youCrusher Service Maintenance Servicing CMS Cepcor Jaw Crusher Maintenance and Inspection author:dahua time: please stop the machine and have a inspection to shot the problem Inspection methods should be: if there has thermometer on the bearing, we can exactly read the current temperature, if there is no temperature for reading, then use hand back to touch on the bearing shell Jaw Crusher Maintenance and Inspection Luoyang

5 Types Of Stone Crushers Application and

The crushers machine are widely used in industries of mining, building materials, roads, railways, water conservancy, and chemical The types of jaw stone crusher: single toggle jaw crusher and double toggle jaw crusher Routine Maintenance During the maintenance of the jaw crushers, wear part is a common occurrenceSometimes, impact crusher (sand making machine) equipment is required according to the process requirements Where, in the stone production line, most of the maintenance work of the equipment is for the maintenance work of the crusher equipment Doing this part of the work will make the maintenance work of the stone production line smoothly Crusher equipment maintenance Hongsheng Maintenance plays an important role in the whole operation Maintaining the crusher machine rationally can maximize the working efficiency, and here are the maintenance tips of the main parts Concave During the crushing process, there is a great impact on the concave which makes the filled zinc layer be out of shapeCone Crusher Tips of Operation and Regular

Maintenance Tips For Jaw Crusher Machine

Regular maintenance and servicing is important if you want to ensure that your machine keeps working as it should for a long period of time You will save a lot of time and money by giving the jaw crusher the attention it needs Here are a few tips to help you maintain your jaw crusher machine Aimix Jaw Crusher Machine Tip One MAINTENANCE OF JAW CRUSHER 1 In order to guarantee normal operation of machine and prolong service life, inject lubrication oil is needed regularly 2 About 50% to 70% of volume of all bearing housings should be filled with grease Change the grease each 36 month, clean the roller bearing carefully 3MAINTENANCE OF JAW CRUSHERLiming Heavy “Successful jaw crusher maintenance requires the right resources, the right tools and the right approach,” says Bill Macini, a Telsmith service technician Certainly when an operation is down, whether for preventive maintenance or component failure, there is always the pressure to get the plant up and running as soon as possibleJaw crusher maintenance : Pit Quarry

Maintenance method during use of jaw crusher Sanme

Maintenance method during use of jaw crusher In the jaw crusher, the wear of the dynamic and static jaw plates can cause the crusher to not operate normally and lose its crushing capacity To ensure the normality of the jaw plate can ensure the normal production of the jaw crusher Jaw Crusher Maintenance and Inspection author:dahua time: please stop the machine and have a inspection to shot the problem Inspection methods should be: if there has thermometer on the bearing, we can exactly read the current temperature, if there is no temperature for reading, then use hand back to touch on the bearing shell Jaw Crusher Maintenance and Inspection Luoyang maintenance plan is recommended for the salt crusher machine II M ETHODOLOGY A Collecting Failure Time Data Collecting Crusher Machine failure data and its components during the specified period, in this case, the year 2016, is done by using the daily logbook of the maintenance personnel After that, the failure time dataReliability Analysis for Preventive Maintenance of Salt

5 Types Of Stone Crushers Application and

The crushers machine are widely used in industries of mining, building materials, roads, railways, water conservancy, and chemical The types of jaw stone crusher: single toggle jaw crusher and double toggle jaw crusher Routine Maintenance During the maintenance of the jaw crushers, wear part is a common occurrenceCrusher Machine For Sale in the Philippines Crusher machine for sale is the mechanical equipment used to crush minerals Generally, a crushing machine can crush different materials, such as river pebbles, granite, limestone, basalt, ore, rock, stone, gypsum, coal, etcAccording to the feed particle size and discharge size, the process of crushing includes three stages, coarse crushing, medium Crusher Machine For Sale in Philippines