عنا

مرحبا هل يمكنني مساعدتك؟

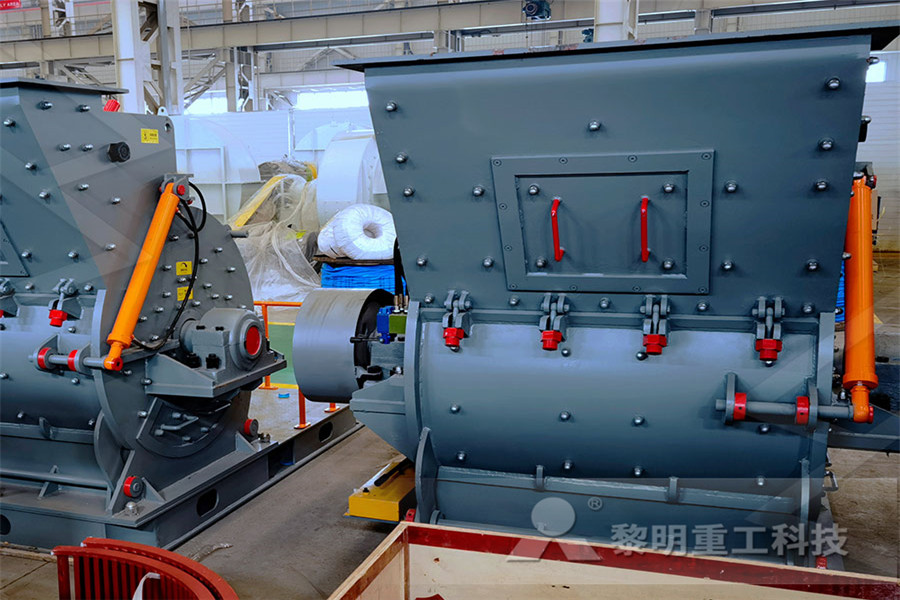

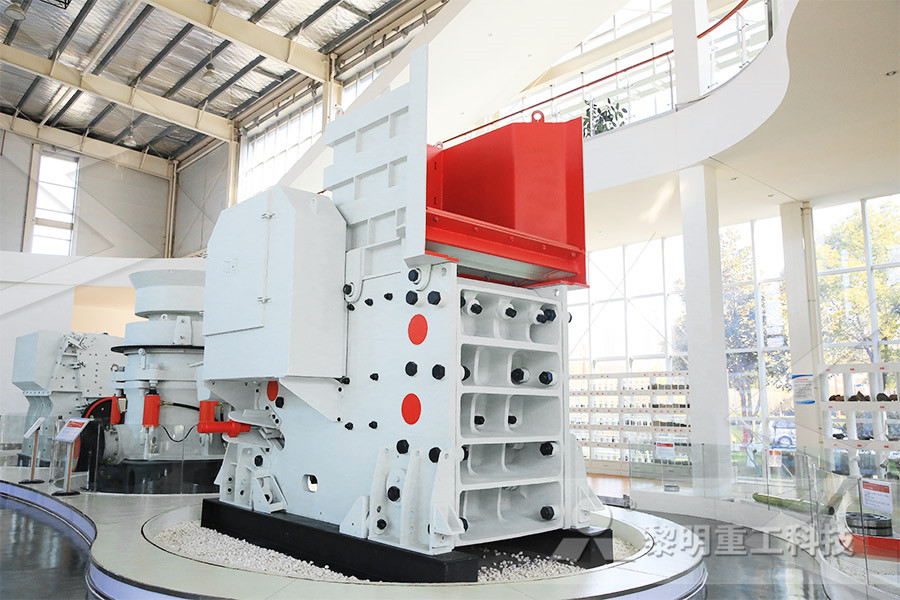

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

production of fine aggregate from earth

2019-09-18T18:09:26+00:00

5 Aggregate Production INgov

aggregate physical properties, and, in particular, gradation (size control) Establishing a stable production process may reduce variability of the product EXTRACTION With the exception of slag and other manufactured aggregates most materials for aggregate production come from bedrock or unconsolidated deposits In this research, the production of stabilized earth bricks with cement using different percentages of soil, and sand has been studied Earth brick are used as a replacement of fired clay bricks and concrete bricks To estimate the effect of these different percentages of component, four percentages with (40% sand, 50% soil, 10% cement), (30% sand, 60% soil, 10% cement), (10% sand, 80% soil The effect of using different percentages of soil and Fine aggregate is one of the ingredients of concrete that needs to get considerable attention in the production of green concrete, and it usually comprises up to 30% to 35% of the total volume of concrete Natural or river sand is the most commonly used fine aggregate in the production of concreteSuitability of Scoria as Fine Aggregate and Its Effect

FineAggregate Concrete Article about Fine

Fineaggregate concrete is used in highway and airfield construction because of the high tensile strength that results from its finegrained structure The absence of coarse aggregate (crushed stone or gravel) substantially facilitates the preparation, transport, and placing of the concrete, particularly when concrete pumps are used The production of conventional concrete is achieved by the use of thereby leading to the reduction in the readily available construction materials on the earth surface Sachin et al (2012) expressed the fact that, to meet the requirements Replacing fine aggregate in the concrete with waste materials such asPARTIAL REPLACEMENTS OF FINE AGGREGATE WITH 2 TYPES OF PRODUCTION Aggregate production is classified into two groups according to the methods of operation Commercial production is defined as production from a permanently established location that supplies aggregate to both commercial consumers and contractors performing KDOT work Some producers may operate in56 AGGREGATES 1 GENERAL 2 TYPES OF PRODUCTION

(PDF) A Review on Artificial Aggregates

The production of artificial lightweight coarse aggregate using fly ash has potential for its largescale utilization in the construction industry and this is an area that merits attention in many SEA SAND AS FINE AGGREGATE FOR CONCRETE PRODUCTION SAMRAJ P ME (CMASE) Under the guidance of DrVNAGARAJAN OBJECTIVE • To find out a suitable method to reduce the salinity in the sand to the permissible level and to study the properties of concrete made with sea sand(PDF) SEA SAND AS FINE AGGREGATE FOR CONCRETE The first stage of aggregate processing involves quarrying where a large deposit of desirable aggregate is identified and extracted from the ground Hardened substances are either blasted or cut into smaller manageablesized rubble and transported by truck or conveyor belts to the processing areaThe Aggregate Manufacturing Process General

Use of pumice fine aggregate as an alternative to

The purpose of this study is to evaluate the possibility of using granulated pumice as an alternative to fine aggregate in production of lightweight cement mortar The cement/pumice fine aggregate ratio is 1:3 for pumice aggregate mortar The water content is determined by flow table test The production of conventional concrete is achieved by the use of thereby leading to the reduction in the readily available construction materials on the earth surface Sachin et al (2012) expressed the fact that, to meet the requirements Replacing fine aggregate in the concrete with waste materials such asPARTIAL REPLACEMENTS OF FINE AGGREGATE WITH The analysis was focused on the aggregate production for the concrete manufacture: fine and coarse aggregate, coming from crushed virgin limestone, and recycled coarse aggregate, obtained from the trituration and classification of concrete debris Limestone is the most common in the study region (Yucatán México)Carbon Footprint of Recycled Aggregate Concrete

Suitability of Ambo Sandstone Fine Aggregate as an

Likewise, the cost of production of the fine aggregate of the Ambo Sandstone quarry site is 140 ETB per cubic meter, while the price of river sand from Legeher Market is 300 ETB400 ETB per cubic meter Therefore, Ambo Sandstone Fine Aggregate (ASFA) is cheaper than the river sandFeldspar is the most common ore in the earth crust and it even appears on the moon and in the aerolite As a material of glass making, feldspar is also used as ceramics industry raw materials, this part takes 30% of the whole dosage Other feldspar is used in chemical, project report on manufactured sand as fine The waste bricks as obtained from garbage of a broken building were collected and pulverized to get the particle passing 475 mm sieve and retained on 0075 mm sieve to get the grading of fine aggregate 5, 10, 15, and 20% brick powder is used as replacement of fine aggregate in the experimentsThe aim of the experiment was to assess the A DETAILED STUDY ON PARTIAL REPLACEMENT OF

Aggregates for Concrete GreenSpec

Fine aggregates are usually sand or crushed stone that are less than 955mm in diameter • Typically the most common size of aggregate used in construction is 20mm A larger size, 40mm, is more common in mass concrete • Larger aggregate diameters reduce the quantity of cement and water needed 20 mm aggregate Common aggregates The other basic components of concrete are sand, gravel (fine and coarse aggregate) and water Chemicals — called admixtures — are sometimes added during the concrete production stage to trap air, remove water, change the viscosity, and alter other performance propertiesHow Cement And Concrete are Made Rediscover The production of conventional concrete is achieved by the use of thereby leading to the reduction in the readily available construction materials on the earth surface Sachin et al (2012) expressed the fact that, to meet the requirements Replacing fine aggregate in the concrete with waste materials such asPARTIAL REPLACEMENTS OF FINE AGGREGATE WITH

Suitability of Ambo Sandstone Fine Aggregate as an

Likewise, the cost of production of the fine aggregate of the Ambo Sandstone quarry site is 140 ETB per cubic meter, while the price of river sand from Legeher Market is 300 ETB400 ETB per cubic meter Therefore, Ambo Sandstone Fine Aggregate (ASFA) is cheaper than the river sandFeldspar is the most common ore in the earth crust and it even appears on the moon and in the aerolite As a material of glass making, feldspar is also used as ceramics industry raw materials, this part takes 30% of the whole dosage Other feldspar is used in chemical, project report on manufactured sand as fine 1119 Construction Aggregate Processing12 The construction aggregate industry covers a range of subclassifications of the nonmetallic minerals industry (see Section 1124, Metallic Minerals Processing, for information on that similar activity) Many operations and processes are common to both groups, including mineral extractionAP 42 1119 Construction Aggregate Processing

Aggregates for Concrete GreenSpec

Fine aggregates are usually sand or crushed stone that are less than 955mm in diameter • Typically the most common size of aggregate used in construction is 20mm A larger size, 40mm, is more common in mass concrete • Larger aggregate diameters reduce the quantity of cement and water needed 20 mm aggregate Common aggregates Wellgraded sand (ie particle size ranging from fine to coarse and free of silt and clay grains) is used as fine aggregate in Portland cement concrete Finetomedium grained sand (preferably with low fines content to increase workability) is used in mortar Fine sands are used in plaster Sand of various qualities and grain sizes is also usedConstruction materials Earth Resources Constituents: coarse aggregate, fine aggregate, cement (limestone and clay), and water “The most bountiful resources on the Earth” Therefore, concrete is the second most consumed material on the Earth after water at present: more than 20 billion tons 1950: 2 billion tonsTCGJSCE Joint Seminar (Sakai)

Mechanical Properties of Concrete Using Steel Slag

Concrete is the most widely used material on earth after water Many aspects of our daily life depend directly or 13 NEED FOR OPTIMIZING AGGREGATE PACKING From the production of concrete, cement is the most expensive material and can account for upto 60% of the slag and replacement of natural fine aggregate with granular slag The Aggregate Designing Buildings Wiki Share your construction industry knowledge Aggregate is the term given to material frequently used in construction as a means of stabilising and reinforcement Aggregates are widely used in drainage applications and as base material under foundations and roads In the 10 years ending in 2010, 25 billion tonnes of aggregates were consumed by the UKAggregate Designing Buildings Wiki aggregate and may be used in other applications Sometimes referred to as #57 aggregate Pleasanton 3/8” Crushed Pleasanton 3/4” X #4 A 3/8” crushed aggregate which must have 100% passing the 1/2” sieve and may have material retained on the 3/8” sieve Typically, an asphalt aggregate but can also be used in concrete and may be used in Environmental Product Declaration ASTM International