عنا

مرحبا هل يمكنني مساعدتك؟

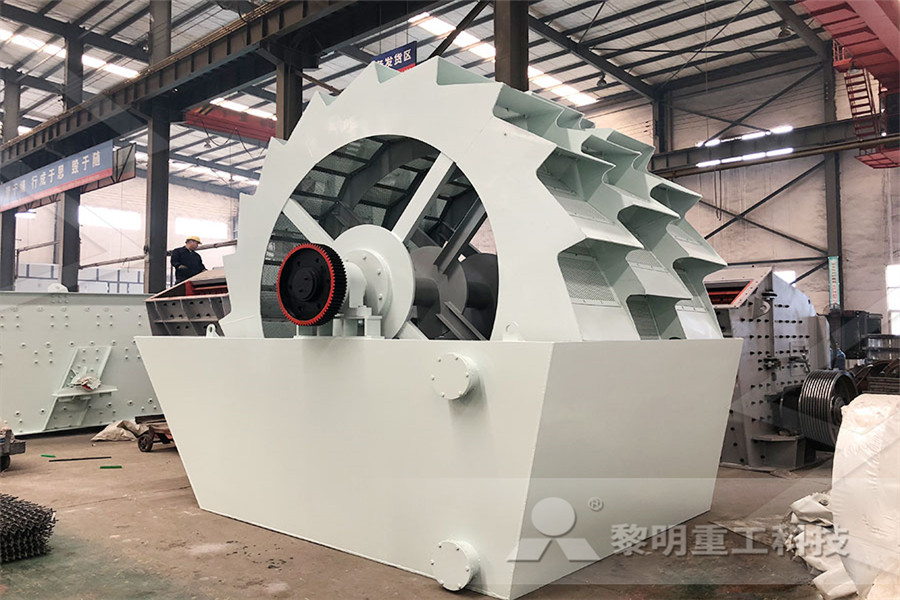

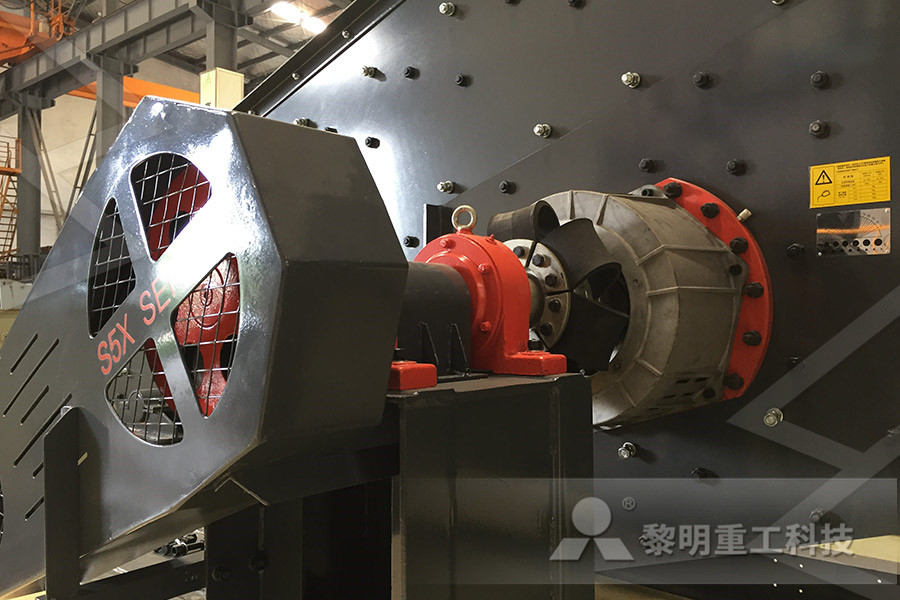

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

barium sulfate depositing

2022-05-14T01:05:48+00:00

Barium Sulfate Scale Formation in Oil Reservoir During

The general purpose of the laboratory test was to investigate permeability reduction by deposition of barium sulfate in a porous medium and knowledge of solubility of barium sulfate and how its solubility are affected by changes in salinity, temperature and pressureThere are two main production processes for depositing barium sulfate: Glauber's salt methodcommonly known as black ash method and sulfuric acid method; the socalled Glauber's salt method is natural barite ore plus coal calcined into barium sulfide, and then reacts with Glauber's salt (sodium sulfate) to form a deposit Barium sulfate and byproduct sodium sulfide; the sulfuric acid method converts barium Precipitated barium sulfate manufacturers By depositing a ferric oxide layer on barium sulfate particles a novel pigment with better optical and functional performance is obtained This pigment in various coating systems improves(PDF) The preparation and characteristics of surface

The preparation and characteristics of surface treated

By depositing a ferric oxide layer on barium sulfate particles a novel pigment with better optical and functional performance is obtained This pigment in various coating systems improves physicochemical performance and acts as an active barrier and functional performance is obtained by depositing a thin layer of ferric oxide on Barium Sulfate particles This pigment in various coating system improves physicochemical performance The treated Barium Sulfate extender pigment acts as an active barrier5 The experimental techniques of surface treatment have beenSynthesis and Characterization of Ecofriendly Barium Most ofthe reduction in core permeability was caused by crystals depositing along andgrowing perpendicular to the pore surface They observed that doubling thesupersaturation ratio of both barium and strontium sulfate produced an increasein the quantity of scale formed inside the pores and a change in the morphologyof the crystalsBarium and Calcium Sulfate Precipitation and

Thermally Stable Catalyst Carrier Comprising Barium

The amount of barium sulfate deposited on the porous support material ranges from greater than 0% to about 20% by weight In one embodiment, the barium sulfate is present an amount ranging from 05% to 10%, 1% to less than 10%, 25% to 75%, 3% to 7%, or 3% to 5% by weight In an embodiment, the barium sulfate is present at about 35% by weightBaSO4based mineral coating was deposited on the surface of the PARO membrane by alternate soaking process (ASP) using aqueous solutions containing barium chloride (BaCl2) and sodium sulfateSurface mineralization of commercial thinfilm A method of preventing barium sulfate scale from depositing in underground petroleum containing formations and upon equipment used to inject barium sulfate scale forming waters which contains at least 1,000 ppm hardness into such formations which comprises treating such waters with a barium sulfate scale inhibiting amount of an acrylic acid polymer which contains from 095 mole percent of Phosphonatecontaining polymers for controlling

Surface mineralization of commercial thinfilm

BaSO4 based mineral coating was deposited on the surface of the PARO membrane by alternate soaking process (ASP) using aqueous solutions containing barium chloride (BaCl 2) and sodium sulfate (Na2 SO 4), respectively Membranes with different mineralization degrees were prepared by varying the number of ASP cyclesCrystals depositing along and growing perpendicular to the pore surfaces caused most of the reduction in core permeability They observed that doubling the supersaturation ratio of both barium and strontium produced an increase in the quantity of scale formed inside the pores and a change in the morphology of the crystals Barium sulfate Barium Sulfate Scale Formation in Oil Reservoir During Provided are barium and an aqueous coating and aqueous ink composition containing the same Deposited by hydroxides and / or oxides (1) of one or more metal elements selected from Al, Si and Zr, and / or phosphates (2) of one or more metal elements selected from Mg, Ca, Sr and Ba It is related with the ultrafine particle barium sulfate KRA Ultrafine Barium Sulfate, Aqueous

Synthesis of Barium Sulfate Nanoparticles and

Supersaturated reverse micelles and microemulsions containing either AOT (sodium bis(2ethylhexylsulfosuccinate)), C12EO4 (poly(oxyethylene4dodecyl ether)), or DDAB (didodecyldimethylammonium bromide) surfactants have been used as organized reaction microenvironments for barium sulfate precipitation Nanoclusters of amorphous barium sulfate, 2−4 T1 Barium and strontium sulfate solid solution formation in relation to North Sea scaling problems AU Todd, A C AU Yuan, M D PY 1988 Y1 1988 N2 This paper presents the results of laboratory experiments carried out to investigate barium sulphate and strontium sulphate solid solution formation in multipressure tapoed coresBarium and strontium sulfate solid solution formation Barium sulfate Basic information Chemical Properties Imaging diagnostic agents Dosage Adverse reactions Precautions Solubility in water (g / 100ml) Chemical Properties Uses Production method Category Toxicity grading Acute toxicity Explosives and hazardous properties Flammability and hazard characteristics Storage Characteristics Professional HENAN SUNLAKE ENTERPRISE CORPORATION

Phosphonatecontaining polymers for controlling

We claim: 1 A method of preventing barium sulfate scale from depositing in underground petroleum containing formations and upon equipment used to inject barium sulfate scale forming waters which contains at least 1,000 ppm hardness into such formations which comprises treating such waters with a barium sulfate scale inhibiting amount of an acrylic acid polymer which contains from 095 mole Disclosed is a method of producing highpurity lithium carbonate and barium sulfate from discarded lithium secondary batteries, including: a first process for producing highpurity lithium phosphate from a discarded battery; and a second process for producing lithium sulfate from the lithium phosphate and producing lithium carbonate and barium sulfate from the lithium sulfateMETHOD OF PRODUCING HIGHPURITY LITHIUM Barium sulfate/regenerated cellulose composite fiber with Xray radiation resistance Measuring the thermophysical properties of porous fibrous materials with a new unsteadystate method Robust ultraviolet shielding and enhanced mechanical properties ofVersatile and ductile cotton fabric achieved via layerbylayer

Scale Inhibitors Shrieve

Shrieve are developing an effective Barium Sulfate Solvent for oilfield applications BIOSCALE 2000 A partially neutralized polyacrylate scale inhibitor designed to prevent calcium carbonate, calcium sulfate, and certain iron scales from precipitating out of solution BIOSCALE 2000 is stable at high temperatures The ratio is controlled via small periodic additions of sulfuric acid; in the event of too much sulfate, additions of barium carbonate are made to precipitate the excess sulfate The "efficiency" of this plating bath is very poor, maybe 1012% [this means that only 1012% of the applied electricity goes towards depositing chrome, and the other FAQ: Hard chrome plating catalysts sulfuric acid vs The most popular approach to address the barium sulfate scale problem has been retarded or prevented the formation of this scale in the first place [6]Many case histories of oil well scaling by calcium carbonate, calcium sulfate, strontium sulfate, and barium sulfate have been reported [7](PDF) Studies on Scale Deposition in Oil Industries

The Effect of Magnetic Treatment on Retarding Scaling

Key Words: Barium sulfate (BaSO4), Calcium Carbonate (CaCO3), Calcium Sulfate (Ca SO4), Magnetic Treatment Introduction Magnetic water treatment (MWT) is a proposed method of water treatment The manufacturers of water treatment devices have claimed that powerful magnetic fields can affect the properties of solutes passing throughSupersaturated reverse micelles and microemulsions containing either AOT (sodium bis(2ethylhexylsulfosuccinate)), C12EO4 (poly(oxyethylene4dodecyl ether)), or DDAB (didodecyldimethylammonium bromide) surfactants have been used as organized reaction microenvironments for barium sulfate precipitation Nanoclusters of amorphous barium sulfate, 2−4 Synthesis of Barium Sulfate Nanoparticles and Barium sulfate Basic information Chemical Properties Imaging diagnostic agents Dosage Adverse reactions Precautions Solubility in water (g / 100ml) Chemical Properties Uses Production method Category Toxicity grading Acute toxicity Explosives and hazardous properties Flammability and hazard characteristics Storage Characteristics Professional HENAN SUNLAKE ENTERPRISE CORPORATION

InNest Behavior of the Carpenter Bee, Xylocopa

barium sulfate Since barium sulfate strongly absorbs Xrays, it is visible on the viewing screen and the Xray plates In this way we were able to distin guish easily between the marked mother and her newly emerged and as yet unmarked progeny During the nesting season, we recognized the teneral bees by their different silhouettes and Xray Soluble sulfate ions in nuclear waste can have detrimental effects on cementitious wasteforms and disposal facilities based on Portland cement As an alternative, Ba(OH)2–Na2SO4–blast furnace slag composites are studied for immobilisation of sulfatebearing nuclear wastes Calcium aluminosilicate hydrate (C–A–S–H) with some barium substitution is the main binder phase, with barium Characterisation of Ba(OH)(2)Na2SO4blast furnace The percentage of sulfate is then calculated from the weight of barium sulfate, this include the molarity and concentration of sulfate, SO 4 2, in g/L 32 Reaction In the experiment, dilute barium chloride is added to an unknown sulfate solution slightly acidified with concentration HClQuantitative Determination of Sulphate UKEssays

ACUMER™ 1000 Midsouth Chemical

Dispersing activity, which prevents precipitated crystals or other inorganic particles from agglomerating and depositing on surfaces AntiPrecipitation Performance ACUMER 1000 polymer is a general purpose scale inhibitor as it is effective to inhibit precipitation of calcium carbonate, calcium oxalate, calcium sulfate, barium sulfate, and The ratio is controlled via small periodic additions of sulfuric acid; in the event of too much sulfate, additions of barium carbonate are made to precipitate the excess sulfate The "efficiency" of this plating bath is very poor, maybe 1012% [this means that only 1012% of the applied electricity goes towards depositing chrome, and the other FAQ: Hard chrome plating catalysts sulfuric acid vs ACUMER 4300 contains maleic and a unique combination of other functionalities to provide both superior calcium carbonate and calcium sulfate inhibition, also outperforming HEDP Preventing calcium sulfate scale is important in water systems treated with sulfuric acid for pH control or ACUMER™ 4300 Midsouth Chemical