عنا

مرحبا هل يمكنني مساعدتك؟

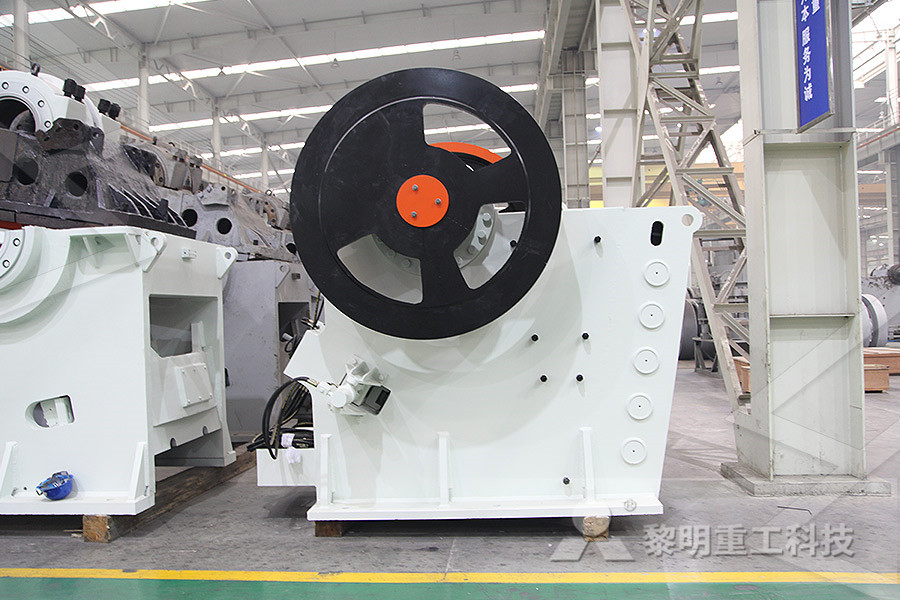

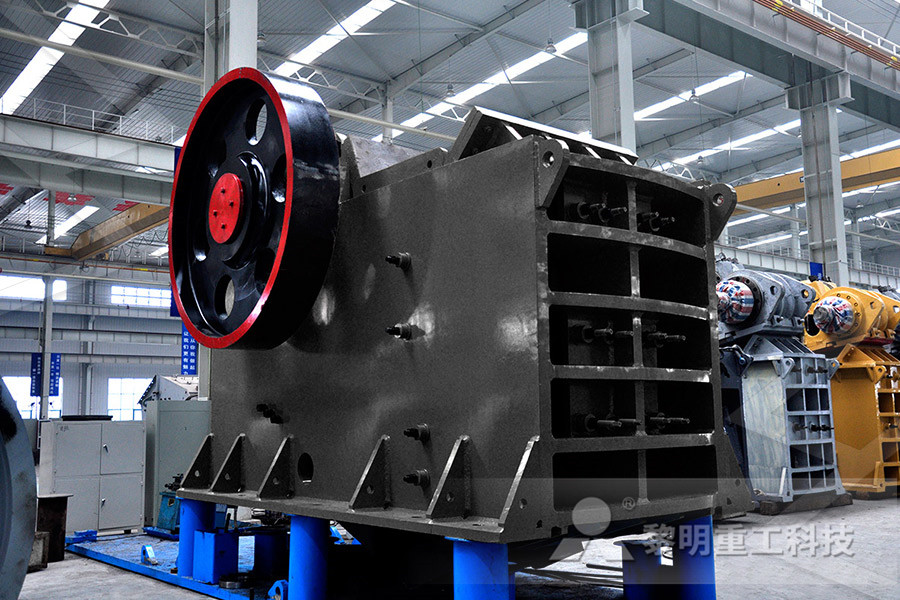

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

fine grinding ore mills

2020-01-19T22:01:51+00:00

Ore ultra fine grinding mill (Isa mill)Sinonine

Working principle of ore ultra fine grinding mill The ultra fine grinding mill is composed of a main shaft, a dispersing disc, a reflecting cage and a bushing During operation, the mechanical energy generated by the rotation of the dispersing disc is transmitted to the grinding medium through the rotation of the main shaft, so that the material is ground and dispersed uniformlyGrinding The ore is ground into a fine powder by large rotating mills The two types used in the Mission South Mill are called SAG (semiautogenous grinding) mills and ball mills SAG mills use larger pieces of ore to break up the smaller pieces (autogenous — does it fine grinding ore mills wczasyaugustow ultra fine grinding mills for gold ore FL Grinding Read about all the different types of grinding mills that FL offers Inquiry Online SIC Codes and Descriptions Numeric Sequence SIC Codes and Descriptions To search for a company's SIC Code use your web browser's "Find" tool which is usually found in your web browser's Edit menuultra fine grinding mills for gold ore

Laboratory Grinding Mill 911Metallurgist

2 天前 Ore Grinding Mills are used for the fine grinding as the last step in the reduction of an ore prior to concentration (gravity or flotation) or cyanidation Practice varies, depending upon the type of ore and the amount of reduction required 1 Introduction11 Background With the continual depletion of high grade simple ore bodies, more complex, finely disseminated ore bodies are being processed, which has led to an increase in the prevalence of fine grinding (Sinnott et al, 2006)This has been evident in the platinum group element (PGE) industry in South Africa, where the Bushveld Complex hosts 70% of global PGE reservesFine grinding: How mill type affects particle shape The fine grinding of ores is increasing due to the depletion of coarse grained, easily processed ore bodies and the increased need to process disseminated, fine grained depositsFine Grinding in a Horizontal Ball Mill Request PDF

ultra fine grinding mills gold ore

Ore testing Swiss Tower Mills Minerals AG We are an innovative company in the regrind, fine and ultrafine grinding industry the well proven fine grinding technology of industrial minerals to the mining industry Concentrate regrinding (gold, copper, moly, platinum, lead, zinc, summary of this fine grinding technology Fine grinding technology use in the mineral process industry has increased over the last 10 years This can be mainly attributed to processing finer grained mineral structures, which requires a finer grind for valuable mineral liberation An example of an ore body with different mineral structureOutotec HIGmills; A Fine Grinding Technology The medium filling rate is the volume ratio of the medium and grinding cavity, moves in throwing and falling state in a ball mill The throwing motion medium is used to smash large ore, and the medium of falling movement mainly plays the role of grinding The filling rate of the fine grinding mill is about 5% lower than that of the coarse grindingFactors Influence Ore Grinding Mill Efficiency JXSC

Swiss Tower Mills Minerals AG

KMF is a leading company specialized in tilting rotary furnaces, mills and grinders, special machinery, plant construction, process engineering and contract manufacturing KMF has over 40 years’ experience in manufacturing fine grinding mills for the industrial minerals industry 1 Introduction11 Background With the continual depletion of high grade simple ore bodies, more complex, finely disseminated ore bodies are being processed, which has led to an increase in the prevalence of fine grinding (Sinnott et al, 2006)This has been evident in the platinum group element (PGE) industry in South Africa, where the Bushveld Complex hosts 70% of global PGE reservesFine grinding: How mill type affects particle shape Mills Used For Fine Grinding Of Ore Ore Grinding Mills Mineral Processing Metallurgy Ore Grinding Mills are used for the fine grinding as the last step in the reduction of an ore prior to concentration gravity or flotation or cyanidationPractice varies, depending upon the type of ore Mills Used For Fine Grinding Of Ore

ultra fine grinding mills gold ore

Ore testing Swiss Tower Mills Minerals AG We are an innovative company in the regrind, fine and ultrafine grinding industry the well proven fine grinding technology of industrial minerals to the mining industry Concentrate regrinding (gold, copper, moly, platinum, lead, zinc, Swiss Tower Mills Minerals AG develops fine and ultrafine grinding mill products, using an innovative technology A range of services is available from consulting, conceptual and detail engineering to production, site assembly and lifecycle service supportSwiss Tower Mills Minerals AGHCH ultrafine grinding mill is especially suitable for ultra fine grinding After a long period of market application practice and user authentication, the device HC1395 model was certified by the China Association of calcium carbonate for energysaving equipment in China's calcium carbonate ultrafine processing industryHCH Ultrafine Grinding Mill Grinding Mills, Ultrafine

Introduction of Alternative Mills for Fine and Ultra

As a consequence, grinding is not economical In this study, alternative fine and ultrafine grinding mills for coal and ore preparation plants, were introduced and their operating principles is explained, in detail the mills that have enhanced their performance THE ISAMILL TECHNOLOGY IsaMill is a major development in grinding technology jointly invented by Mount Isa Mines of Australia and Netzsch Feinmahltecknik GmbH of Germany for ultrafine and fine grinding duties in the minerals industry The IsaMill was introduced by MIM over a period of 9 years, as ISAMILL FINE GRINDING TECHNOLOGY AND ITS Fine grinding media inside the mill are agitated or rotated by a stirrer, which typically comprises a central shaft to which are attached pins or discs of various designs Stirred mills find application in fine (15 40 m) and ultrafine (15 m) grindingChapter 7: Grinding Mills Engineering360

Factors Influence Ore Grinding Mill Efficiency JXSC

1 Ore particle size In the most grinding process of the concentrator, the construction investment and production and operation cost of grinding operation is much higher than those of crushing operation, so it is necessary to reduce the grinding particle size as much as possible The grinding machine was a laboratoryscale ball mill made of stainless steel with the dimensions 200 × 200 mmThe grinding media were stainless steel balls with a density of 8000 kg/m 3 and with three different diameters (ie, 2, 3, and 4 cm) Powder density was found to be 23 g/cm 3The grinding experiment was performed as a batch process; after each test, all media and ground samples An experimental study on the ultrafine grinding of Mills Used For Fine Grinding Of Ore Ore Grinding Mills Mineral Processing Metallurgy Ore Grinding Mills are used for the fine grinding as the last step in the reduction of an ore prior to concentration gravity or flotation or cyanidationPractice varies, depending upon the type of ore Mills Used For Fine Grinding Of Ore

RoStar™ Vertical High Intensity Ultrafine Grinding

Typical Applications or RoStar Ultrafine Grinding Ultra Fine Grinding of Refractory Mineral Concentrates Leachox process™ In this application a refractory gold orebody, typically a pyrite/arsenopyrite ore, is ground to approximately 80100% 74 microns in Rod mill Description: Rod mill is known as the grinding medium in the cylinder body is steel bar,rod mill is generally use the wet overflow type and can be widely used as the first level open grinding in artificial sandstone,beneficiation, chemical industry The product size characteristics of rod mill is related to crushing ,In the grinding process ,it first crush the coarse grain, and then rod mill china,ultra fine grinding mills,grinding As a consequence, grinding is not economical In this study, alternative fine and ultrafine grinding mills for coal and ore preparation plants, were introduced and their operating principles is explained, in detailIntroduction of Alternative Mills for Fine and Ultra

Fine Grinding Technology for Mines and

A paper in Minerals Engineering ("Comparison of Energy Efficiency Between Ball Mills and Stirred Mills in Coarse Grinding", Vol 22 (2009) 673680) reported the energy use of ball mills versus vertical tower and horizontal stirred mills Both coarse and fine grinding applications were investigated Fine grinding media inside the mill are agitated or rotated by a stirrer, which typically comprises a central shaft to which are attached pins or discs of various designs Stirred mills find application in fine (15 40 m) and ultrafine (15 m) grindingChapter 7: Grinding Mills Engineering1221 Three features of stirred mills that transform the economics of fine grinding are : the high intensity attrition grinding environment the ability to use fine grained media (eg 1 mm) to suit to the fine grained feed the ability to use cheap natural products (local sand, slag, ore) as grinding mediaFine Grinding as Enabling Technology – The IsaMill

MicroGrinding Systems, Inc EnergyEfficient

The VibroKinetic Energy (VKE) Mill is designed to fill the need for a fine to ultrafine grinding mill which is both low cost and economical to operateOptional features include air classification while dry grinding, which greatly improves the efficiency of the mill Wet grinding with hydrocyclone recycle for accurate sizing, and use of vibratory table for concentration of ore values is also Grinding mills used in iron ore grinding Ball mill is used as iron ore grinding mill In iron ore concentrator, ball mill and regrinding ball mill is used to grind iron ore into fine powder Iron ore crushing plantAlmost all of the iron ore that is mined is used for makingIron Ore Crushing and Grinding Machines liajones 博客园Crushed ore is fed into Mills in which the ore is mixed with water and may be ground down to a particle size, in the case of gold and copper, of about 75 microns (0075mm) The fine, powdered ore emerges from the mills mixed with water in a thin, wet paste called Pulp or SlurryMilling Mineral Processing Extractives Hub