عنا

مرحبا هل يمكنني مساعدتك؟

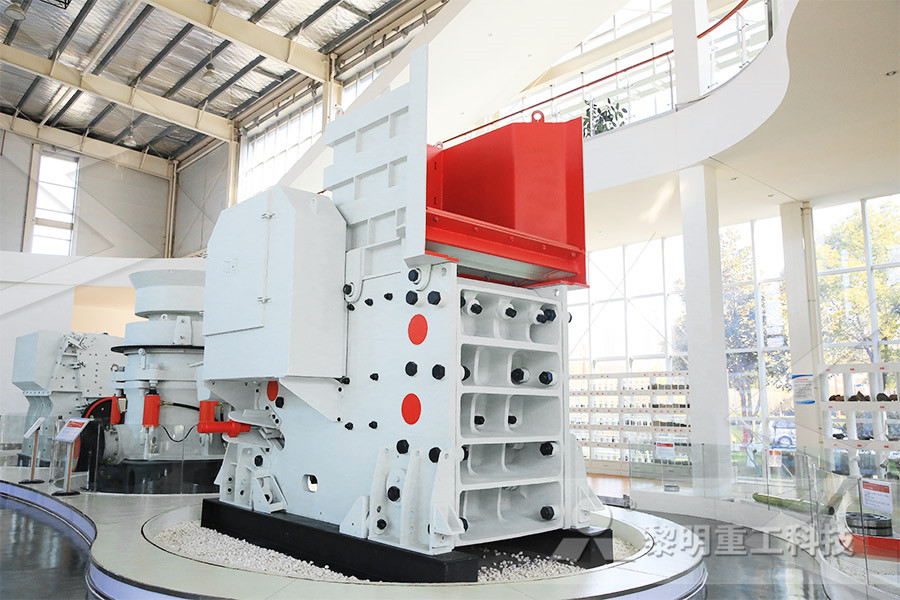

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Mineral Processing Crushed

2021-07-01T21:07:15+00:00

Mineral Processing Silver

Mineral Processing The mined ore is crushed and milled before the flotation process to desired grain size Crushing is done in two phases followed by milling in the bar and ball mills The flotation process is conducted in the stages The first stage is the silvergoldlead flotation which is followed by the zincsilver flotation and pyrite Modern mineral processing techniques typically use mechanized unit processes to separate minerals from ore The first process is typically comminution, which can consist of crushing or grinding an ore This procedure can break minerals out of What is Mineral Processing? (with pictures)The Purpose Of Crushing In Mineral Processing Mineral Processing is crushing and separating ore into valuable substances or waste by any of a variety of techniques Most ores, however, are made up of hard, tough rock masses that must be crushed before the valuable minerals can be released get price ore is crushed so that the mineral can be releasedore is crushed so that the mineral can be released

Mineral processing metallurgy Britannica

2 天前 Alternative Titles: mineral dressing, ore dressing Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in Nonmetallic mineral processing plants are commonly referred to as rock crushers These plants use equipment to crush or grind any nonmetallic minerals wherever located, including lime plants, power plants, steel mills, asphalt concrete plants, Portland cement plants or any other facility processing nonmetallic mineralsNonmetallic Mineral Processing Plants "Crushers" emission factors for pulverized mineral processing operations Pulverized mineral processing operations share the same extractive, crushing, and screening processing operation with crushed stone plants Pulverized mineral operations continue to process the material to produce materials having an extremely small particle size distributionResponse to Comments, AP42 Section 11192 Crushed

Mineral Sampling ScienceDirect

Mineral Processing Design and Operations Mineral Processing Design and Operations (Second Edition) An Introduction 2016, Pages 131 A gold ore was crushed in a jaw crusher down to 3 mm and to 1 mm in a cone crusher and finally in a rod mill to minus 75 μm and sampled at each stage The standard deviation at the first stage was ±10 ppm AP 42 Section 11192 Crushed Stone Processing and Pulverized Mineral Processing Response to Comments The information in this document has been funded by the National Stone, Sand and Gravel Association (NSSGA) for the US Environmental Protection Agency (EPA)AP 42 Section 11192 Crushed Stone Processing and Category: Mineral processing Henan Dewo Machinery Mining Construction Solutions such as aggregates processing, construction waste recycling, mineral processing ore introduction: It mainly includes three processes of crushing, grinding and beneficiationGenerally, the ore is crushed to 6~0mm or 10~0mm, and then grouped, the coarse level Mineral processing – Mining Machinery Mobile Rock

mineralprocessing NTNU

At the Mineral Processing Laboratory, ores and mineral based raw materials are crushed and ground in order to liberate the individual phases These particles can then be separated to recover valuable minerals, remove contaminating components or divide the material into different size fractions The separation is based on differences in the how is gold crushed in mineral processing samples of the crushed stones riiaplicada samples of the crushed stones iihed samples of the crushed stones samples of the crushed stones white stone calcium inc Quarrying Crushers are mainly Inquiry Online The Mineral Talc Uses Properties Photoshow is gold crushed in mineral processingThe primary operations are comminution and concentration, but other essential operations in a modern mineral processing plant include sampling and chemical, mineralogical and particle size analysis However, the common factor in minerals processing plant involves the primary crushing of extracted natural materials; a highly efficient process MINERALS PROCESSING

Some Problems in the Crushing and Grinding Stage of

However,there are quite a few mineral processing plants with the disadvantage of incompatible crushing and grinding equipment and technology: guaranteeing the size of crushed products cannot guarantee the output, while guaranteeing the output may lead that the size of crushed products is too large AP42 SECTION 11192 CRUSHED STONE PROCESSING AND PULVERIZED MINERAL PROCESSING NOTICE The information in this document has been funded by the National Stone, Sand and Gravel Association (NSSGA) for the US Environmental Protection Agency (EPA) It has been reviewed by the EPA Office of Air Quality Planning and Standards and hasResponse to Comments, AP42 Section 11192 Crushed Mineral processing in the digital age the process whereby rocks are crushed or ground into smaller fragments, is one of the most energy intensive processes on a Mineral processing in the digital age Australian Mining

(PDF) Comminution in mineral processing

The aim of mineral processing is to get the mineral from rock or Ore that has good economic value in the market Generally, the ability of treating crude material from excavation into mineral A Gupta, DS Yan, in Mineral Processing Design and Operation, 2006 613 Roll Crusher Circuit Design Roll crushers are generally not used as primary crushers for hard ores Even for softer ores, like chalcocite and chalcopyrite they have been used as secondary crushers Choke feeding is not advisable as it tends to produce particles of irregular sizeCrusher an overview ScienceDirect TopicsCrushing in Mineral Processing In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocksmineral processing and crushing technonogy

mineral processing does a crushed mineral maintain

mineral processing news and technology bulkinsidelearn about innovations and news from the mineral processing industry and mineral are required to prepare and classify ores before the valuable materials can be separated crushing, grinding, milling, and vibration (feeding) are examples of they all need to keep up to date with the latest mineral processing news(pdf) minerals recovery and AP 42 Section 11192 Crushed Stone Processing and Pulverized Mineral Processing Response to Comments The information in this document has been funded by the National Stone, Sand and Gravel Association (NSSGA) for the US Environmental Protection Agency (EPA)AP 42 Section 11192 Crushed Stone Processing and 2 天前 Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other important operations Mineral processing metallurgy Britannica

how is gold crushed in mineral processing

how is gold crushed in mineral processing samples of the crushed stones riiaplicada samples of the crushed stones iihed samples of the crushed stones samples of the crushed stones white stone calcium inc Quarrying Crushers are mainly Inquiry Online The Mineral Talc Uses Properties PhotosMineral Processing Overview Mankind has successfully extracted metals from ore for thousands of years This topic provides an overview of the typical processing activities which may be found on mine sites today Very few mines extract products directly from excavations for sale without some form of processingMineral Processing Mineral processing typically involves the crushing and grinding of hard rock ore Crushed ore is introduced to semiautogenous grinding (SAG) mills, also known as primary mills, where grinding media is released like hammers to assist in the ore cracking / grinding processSino Grinding Mineral Processing

(PDF) SIZE REDUCTION BY CRUSHING METHODS

crushed until it is small enough to fall out thr ough the gap between the two surfaces Mineral processing involves two major categories of processing One is comminution and the other one is Mineral processing in the digital age the process whereby rocks are crushed or ground into smaller fragments, is one of the most energy intensive processes on a Mineral processing in the digital age Australian Mining Mineral Processing Design and Operations Mineral Processing Design and Operations (Second Edition) An Introduction 2016, Pages 131 A gold ore was crushed in a jaw crusher down to 3 mm and to 1 mm in a cone crusher and finally in a rod mill to minus 75 μm and sampled at each stage The standard deviation at the first stage was ±10 ppm Mineral Sampling ScienceDirect