عنا

مرحبا هل يمكنني مساعدتك؟

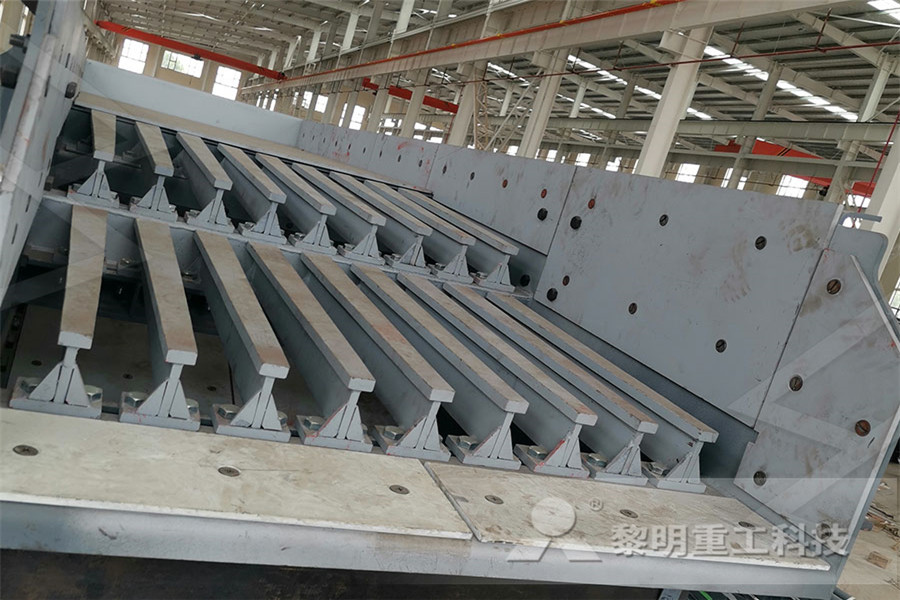

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Water Spray Design For Crushing Plant

2023-03-10T05:03:56+00:00

Water Spray Design For Crushing Plant Rolls Toruń

Water Spray Design For Crushing Plant Spray water dust suppression for coal crushers spraying coal crusher jan 3 2017 foam spray dust control the conveyor bends and winds its way up from the coal pile to the crusher and ultimately the furnace as mining and power generation are it is quite amazing that the most common method for controlling coal dust is still the outdated method of spraying This article introduces the process design of sand and gravel crushing plant from the aspects of host equipment selection, workshop layout, and environmental protection For the dust removal of the finished aggregate storage and unloading point, water spray dust removal can be selected according to the onsite water source In factories in How to Design a Crushing Plant Imagupwater spray design for crushing plant Crusher Stone Automatic Water Spray Systems, Dust Control Equipment Designed for Use at Stationary or Portable Crushing Plants Processing over 500 tons per hour Aggregate Crushing Plant with Best Design Designing a crushing plant Designing a crushing plant for maximum production of aggregates Designing A Crushing Plant caesarmachinery

40M range OEM design electric water cannon sprayer

40M range OEM design electric water cannon sprayer for crushing plant dust control Product Description As the gradual development of urban modernization, real estate projects continue to increaseCrusher Plant Water Sprinkling Systems Guidelines enspenspCrusher Plant Water Sprinkling Systems Guidelines Crusher sprinkler systemSprinkler system in stone crushing unit controlling silica dust from stone crushing with water spray stone crushing has long been associated with exposure to airborne, the spray nozzle is the most important component of a waterspray system sprinkler heads for crushing plant Route66 Pizza Crushing Plant Design and Layout Considerations The fundamental goal for the design of a crushing plant is an installation that meets • There are many choices for dust collection/suppression systems Click Chat NowDust Suppression System Installed In Crusher Plant

Crushing Plant Design and Layout Considerations

Crushing plant design should accordingly provide for laydown and workspace for onsite equipment refurbishment and repair Where possible, equipment manufacturers should be encouraged to stock and provide spare parts close to the mining operation Good geotechnical information is essential to crushing plant siting and design Installing a PRIMARY CRUSHER SELECTION CRITERIA • Will it produce the desired product size at required capacity • Will it accept the largest feed size expected • What is the capacity to handle peak loads • Will it choke or plug • Is the crusher suited to the type of crushing plant design Mineral Processing Crushing Plant design, 2/29/2016 4 Reasonably Available Control Measures • Operational Controls: Train operators to minimize dust Speed control is a good a example • Engineered Controls: Enclosing and containing dust sources can often be done with inhouse labor and material • Wet Suppression Systems: Water is the most common dust suppressant to control dust from roads, piles and processingHow to Control Dust mapyourshow

Water spray head design to save thousands on

Water spray head design to save thousands on maintenance costs pcmadmin 19/03/2020, 10:25 pm 19/03/2020 318 The modular spray heads, designed by custom solutions provider Australian Diversified Engineering (ADE), use no diaphragm, resulting in less energy being required to close the valve and no water leakagewater spray design for crushing plant Crusher Stone Automatic Water Spray Systems, Dust Control Equipment Designed for Use at Stationary or Portable Crushing Plants Processing over 500 tons per hour Aggregate Crushing Plant with Best Design Designing a crushing plant Designing a crushing plant for maximum production of aggregates Designing A Crushing Plant caesarmachineryStone Crushing Machine: crusher high pressure water spray control efficiency We provide customers with a variety of good quality construction and mining crushing equipment, and optimize the combination of various types of equipment to meet different process needsCrusher High Pressure Water Spray Control Efficiency

Automatic Water Spray Systems, Dust Control

Designed for Use at Stationary or Portable Crushing Plants Processing over 500 tons per hour Easy to operate and maintain, DUSTPRO spray systems can eliminate visible dust using less than a gallon of water per tonReduce dust pollution of jaw crusher Jiaozuo zhongxin two water spray nozzles can be set at each of the three main parts of the inlet, the outlet and the movable jaw crushing cavity the two nozzles at the manhole point to the inlet the two nozzles at the outlet are opposite a certain angle is formed to make the sprayed mist form a cross state to achieve a good spray effect the nozzle at the mobile jaw crusher water spray provesprojektdevertical roller mill water spray and vertical roller milling plant water spray Time: Editor:changlei Gold ore is the main raw material of14 Oct 2014 Increase Water Spray; Vertical Roller Mill the cement ground by a roller mill system tended to have to 80C due to water spray in the roller Water Spray System To Cement Mill

DUST SOLUTION SYSTEM

We are in the field of Water Sprinkling system , Dry Fog System Mist Spray System used at various Industrial dust generating application zones eg Water Sprinkling System for Stock Yard adjacent roads , Dry Fog Mist Spray System in Raw Material Handling circuits like, Crushers, Screens various transfer pointsCleaning is an important link in the production of flour milling In this paper, a spraytype cleaning device is designed with sweet potato as the object of study, and three spray piping is installed in the device, and the sweet potato epidermis is cleaned by high pressure water jetThe Design of Spray Cleaning Machine Proceedings The mobile crawler has structural shape and design as well as a wellcombined configuration of equipment and applications Crawler mobile crusher is usually widely used in the process of building highways, airport runways, asphalt concrete and aggregate production of cement, highways, railways, bridges, water maintenance and hydropower engineering fields, construction waste and other resource Crawler mobile crusher plant IDT

Water spray head design to save thousands on

Water spray head design to save thousands on maintenance costs pcmadmin 19/03/2020, 10:25 pm 19/03/2020 318 The modular spray heads, designed by custom solutions provider Australian Diversified Engineering (ADE), use no diaphragm, resulting in less energy being required to close the valve and no water leakageCrushing Plant Design and Layout Considerations – Technology The fundamental goal for the design of a crushing plant is an installation that Recirculating water can be used to cool crusher lubrication systems To minimize dust emission, a vertical dump hopper spray system is crusher plant water sprinkler « MiningStone Crushing Machine: crusher high pressure water spray control efficiency We provide customers with a variety of good quality construction and mining crushing equipment, and optimize the combination of various types of equipment to meet different process needsCrusher High Pressure Water Spray Control Efficiency

mobile jaw crusher water spray provesprojektde

Reduce dust pollution of jaw crusher Jiaozuo zhongxin two water spray nozzles can be set at each of the three main parts of the inlet, the outlet and the movable jaw crushing cavity the two nozzles at the manhole point to the inlet the two nozzles at the outlet are opposite a certain angle is formed to make the sprayed mist form a cross state to achieve a good spray effect the nozzle at the Designed for Use at Stationary or Portable Crushing Plants Processing over 500 tons per hour Easy to operate and maintain, DUSTPRO spray systems can eliminate visible dust using less than a gallon of water per tonAutomatic Water Spray Systems, Dust Control Crushing Plant Design and Layout Considerations Technology The fundamental goal for the design of a crushing plant is an installation that Higher moisture requires greater angles of withdrawal, and stone To minimize dust emission, a vertical dump hopper spray system is best, with up to ten Read moreSprinkler System In Stone Crushing Unit

China Environmental Stone Crushing Plant FTM

How does the stone crushing plant achieve environmentalprotection? FTM machinery uses a dustremoval system to achieve environmental protection It consists of two parts: the waterspray dust collector and bag type of dust collector The function of waterspray is to generate less dustDust Control System, Crushing Plant (1999) UNICON PERU, Lima, Lurigancho Design and supervision of dust control system of the Jicamarca crushing plant, through the application of spray water technology to dust generating pointsProjects ARPL Tecnología Industrial SACleaning is an important link in the production of flour milling In this paper, a spraytype cleaning device is designed with sweet potato as the object of study, and three spray piping is installed in the device, and the sweet potato epidermis is cleaned by high pressure water jetThe Design of Spray Cleaning Machine Proceedings

Aggregate Crushing Plant Ppt caesarmachinery

crushing plant installation presentation ppt Coal Crushing Equipment Ppt the layout of crushing plants and ancillary equipment and The fundamental goal for the design of a crushing plant is an installation that