عنا

مرحبا هل يمكنني مساعدتك؟

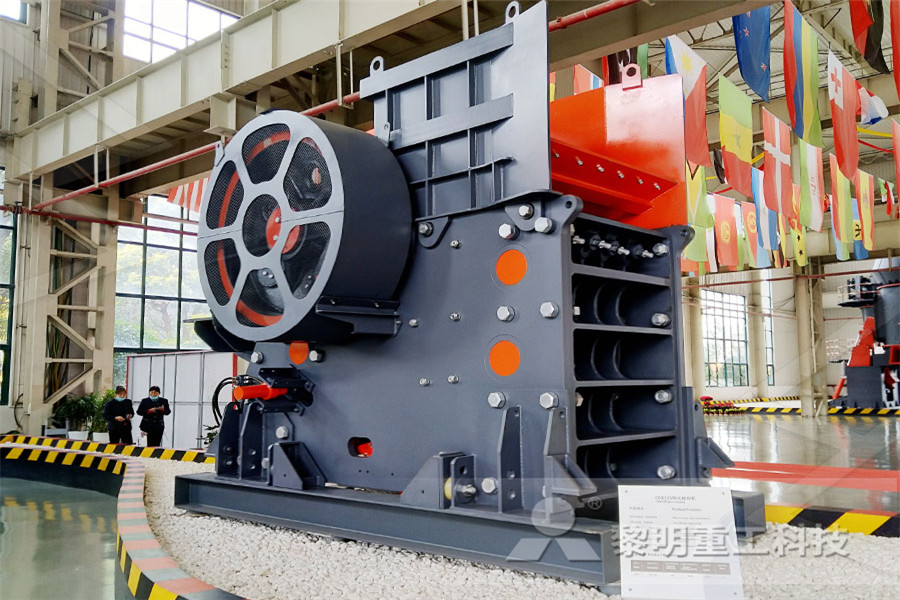

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

grinding media for minerals

2021-12-11T00:12:23+00:00

Grinding Media Balls for Mines and Minerals

GRINDING MEDIA FOR THE MINING INDUSTRY There is no standard solution for mineral industry and wear rate of grinding media varies from mine to mine, ore to ore and even for the same ore time to time Different alloys are recommended depending on ore type and mill particulars in order to arrive at the most cost economic solution Chemshun Ceramics grinding media for mining and mineral is small size ceramic balls or ceramic beads, used in high intensity stirred mills for fine and ultra fine grindingCeramic Grinding Media Balls for Mining Chemshun Middle density ceramic grinding media: CS32, CS36, CS38, CS40, which widely used in the grinding mill of mining and minerals and suitable for hard minerals, high density slurry of minerals The series media improve cost efficiency of customerCeramic grinding media for mining industryCeramic

Minerals Free FullText Grinding Media Motion and

The local grinding media concentration, velocity profiles, grinding media collisions and stress energies were compared for varied total grinding media fillings and stirrer speeds It was confirmed that the normalized grinding media velocity profile can be used to divide the grinding chamber into four types of zones that allow the modeling of the stress energy distributionThe work by Forssberg, Yuan and their collaborators found that the grinding of minerals with nonferrous medium, the pulp potential, conductivity and total sulfur concentration of sulfide minerals were higher than those ground with ferrous medium [ 6, 7, 8, 9, 10 ]Effects and Mechanism of Different Grinding Media Grinding of minerals are carried out in the mills There are different types of the grinding media used in grinding According to the geometric shape of grinding media there are: The balls of different diameters;TYPES OF GRINDING MEDIA energosteel

3 Types of Grinding Media for Ball Mills FTM

Electrochemical interactions between the grinding media and minerals, occur especially in wet grinding; resulting in media corrosion In the same ball mill, the corrosion rate on the surface of each medium will be the same regardless of the size of the millOne of the basic operations in minerals processing is grinding of the ore to the point where valuable minerals are liberated from the host rock Subsequent operations then separate the desirable minerals from the gangue or waste The grinding balls form the major portion of the consumable costs, and can be as high as 40% to 45% of the total costs of communition[PDF] Grinding media quality assurance for the GRINDING MEDIA QUALITY ASSURANCE FOR THE COMMINUTION OF GOLD ORES 27 Introduction One of the basic operations in minerals processing is grinding of the ore to the point where valuable minerals are liberated from the host rock Subsequent operations then separate the desirable minerals from the gangue or wasteGrinding media quality assurance for the comminution of

Stirred media mills in the mining industry: Material

These can be rod mills which are suitable for relatively coarse grinding, and ball mills which are practically capable of grinding down to finer sizes Both types use a rotating shell containing either rod or ball shaped grinding media, which are lifted and dropped as the mill rotates, grinding the charge down with impact and attrition forcesNumerous minerals, both hard and soft, must be finely ground before use in ceramic products Key Properties: Exceptional hardness density, wear resistance, uniform sizing, low end product contamination YTZ Zirconia YTZ Zirconia Grinding Media offers exceptional hardness and density, allowing manufacturers to achieve superior levels of Grinding Media RBH LtdRBH LtdGrinding of minerals are carried out in the mills There are different types of the grinding media used in grinding According to the geometric shape of grinding media there are: The balls of different diameters; Short cylinders — steel circle cut into the size; Steel bars TYPES OF GRINDING MEDIA energosteel

Grinding media / Grinding balls CIMAP

Mining operations require grinding media or grinding balls for crushing minerals or rock extracts in order to seperate them and obtain pure powders Crushing is done by contact between the grinding balls and the minerals which are placed together inside big mixing containers : the grinding balls crush the raw ore thanks to their weight and Grinding media have significant influence on the flotation of chalcopyrite and pyrite This effect is mainly related to the change in the surface properties of chalcopyrite and pyrite This paper investigates the influence of steel ball and nanoceramic ball grinding on the floatability of chalcopyrite and pyrite Flotation results, as wellscanning electron microscopy (SEM), Xray Frontiers Effect of Grinding Media on Grinding Grinding Media Proven in a wide variety of applications, eg as grinding beads in agitator bead mills for the finest comminution and dispersion of pigments, paints, minerals and ceramic powdersGrinding media High quality ceramic grinding beads

Tuning the Morphology and Surface Property of

Grinding of minerals for particle size reduction and liberation is a prerequisite for successful mineral flotation separation and powder modification Different grinding media produce mineral particles with different physical morphology and surface chemistry properties Different mill particles expose different proportions of cleavage surfaces which lead to different shape indexes and Cast High Chrome grinding media has been designed to effectively liberate a wide variety of minerals such as gold, silver, lead, zinc, copper, iron, etc during the comminution process The chemistries have been designed for use in mining applications to ensure optimal product performanceCast High Chrome MolycopGrinding balls from Forsbacka Kulverk are used by one of the world’s leading processors of iron ore products in their primary mill, just prior to flotation and magnetic separation Every month, ton after ton, the grinding media helps them to secure the costefficient production of ore pellets renowned for their high purity level Superior Superior grinding media from Forsbacka Kulverk

Grinding Equipment Systems Grinding Media

The materials and sizes of the grinding media of your equipment can be selected according to the different characteristics and requirements of the abrasive materials to achieve various results For example, larger abrasive media are suitable for grinding larger or denser structures, smaller abrasive media can grind fine particles to smaller (iii) In two sulphide mineralsmedia (pyrite/chalcopyrite/media) systems, pyrite is the noblest electrode acted as cathode and the grinding media always as anode whilst chalcopyrite with lower rest potential than pyrite but higher rest potential than the medium developed an Galvanic Interaction between Chalcopyrite and Pyrite Ceramics grinding media for Mining and Mineral Chemshun Ceramics grinding media for mining and mineral is small size ceramic balls or ceramic beads , used in high intensity stirred mills for fine and ultra fine grindingThe ceramic grinding beads is ideally suited as the cost effecient alternative for High Intensity Mills such as the Glecore IsaMill, Outotec HIGMill, SMD Mills,as well as Ceramic Grinding Media Balls for Mining Chemshun

Grinding media / Grinding balls CIMAP

Mining operations require grinding media or grinding balls for crushing minerals or rock extracts in order to seperate them and obtain pure powders Crushing is done by contact between the grinding balls and the minerals which are placed together inside big mixing containers : the grinding balls crush the raw ore thanks to their weight and GRINDING MEDIA QUALITY ASSURANCE FOR THE COMMINUTION OF GOLD ORES 27 Introduction One of the basic operations in minerals processing is grinding of the ore to the point where valuable minerals are liberated from the host rock Subsequent operations then separate the desirable minerals from the gangue or wasteGrinding media quality assurance for the comminution of One of the basic operations in minerals processing is grinding of the ore to the point where valuable minerals are liberated from the host rock Subsequent operations then separate the desirable minerals from the gangue or waste The grinding balls form the major portion of the consumable costs, and can be as high as 40% to 45% of the total costs of communition[PDF] Grinding media quality assurance for the

The Effect of Grinding Media and Environment on the

When sulfides and grinding media are in contact with each other, galvanic cells are formed and redox reactions take place due to the differences in the opencircuit potentials of sulfide minerals and grinding media The galvanic reactions are controlled by the mixedpotential principleGrinding media have significant influence on the flotation of chalcopyrite and pyrite This effect is mainly related to the change in the surface properties of chalcopyrite and pyrite This paper investigates the influence of steel ball and nanoceramic ball grinding on the floatability of chalcopyrite and pyrite Flotation results, as wellscanning electron microscopy (SEM), Xray Frontiers Effect of Grinding Media on Grinding Grinding Media Proven in a wide variety of applications, eg as grinding beads in agitator bead mills for the finest comminution and dispersion of pigments, paints, minerals and ceramic powdersGrinding media High quality ceramic grinding beads

About Keramos Grinding Media

Keramos is an Australian based and registered company with over 20 years experience in the manufacture and supply of exceptional quality cutting edge ceramic grinding media into the mining and minerals industriesGrinding of minerals for particle size reduction and liberation is a prerequisite for successful mineral flotation separation and powder modification Different grinding media produce mineral particles with different physical morphology and surface chemistry properties Different mill particles expose different proportions of cleavage surfaces which lead to different shape indexes and Tuning the Morphology and Surface Property of Zhiyong has developed a method to regulate the crystal surface exposure and hence particle reactivity of different minerals by optimizing the grinding media parameters Based on these fundamental studies, various new reagent schemes and grind technologies have been developed and utilized to optimize the currently used separation process and address key environmental and energyrelated 中南大学 高志勇 Central South University