عنا

مرحبا هل يمكنني مساعدتك؟

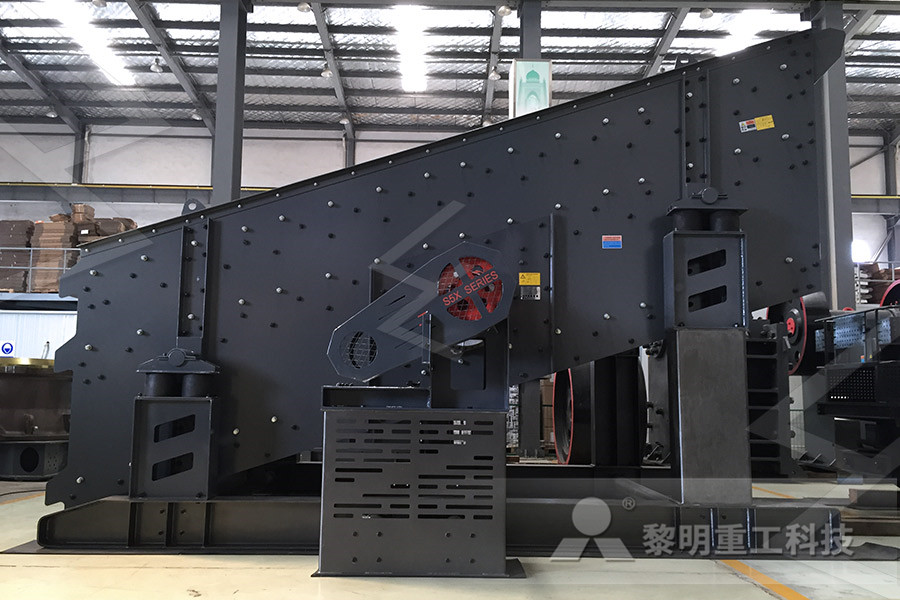

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Process Of Two Roll Mill

2021-12-26T16:12:54+00:00

Roll Mill an overview ScienceDirect Topics

James L White, Kyonsuku Min, in Comprehensive Polymer Science and Supplements, 1989 932 Tworoll Mills The tworoll mill was used in industrial operations of various types well into the dimmest pastIt was, however, only with the 1836 patent of Chaffee 31 that roll mills began to be used in the polymer industry Chaffee 32 sought to use roll mills and calenders in place of the solution Tworoll mills Strongly designed TwoRoll Mills of any size and for any application are ready to our customer´s disposal Many years experience on this field is transferred on very powerful equipment Having a full control on manufacturing process on the mill rolls give us a large advantageTwoRoll Mills BUZULUK asThe process is mixing is carried out between two contrary rotors The wicks of the both the rotors are arranged in parallel manner and posses different speeds Due to the difference in tangential speed and nip constriction, rubber compound experiences Two Roll Mixing Mill Two Roll Rubber Mixing Mill

PROCESS OF ROLLING MILLS LinkedIn

Many shapes and sections are possible to roll by the steel rolling process The difficulty in the removal of the heat from the roll is the result of two factors The goal of mill and the Roll selection for a mixing mill is of decisive importance for the quality of many hightech products manufactured by the rubber industry Open tworoll mills in rubber processing are recommended when quick cooling for the batch being mixed is sought, say for example in final mix compoundsTwoRoll Mill Rubber Tyre Machinery WorldSantec's Two Roll Mixing Mills are widely used for mixing and kneading raw rubber, synthetic rubber, thermoplastics or EVA with chemicals into even materials The even materials can be fed to calender, hot presses or other processing machinery for Two Roll Mixing Mills Two Roll Rubber Mixing Mills

Rolling Process: Working, Application, Defects, Type of

Rolling is the deformation process of a metal that is widely used in the metal forming process in opposite directions In this mill, between the first and the second rolls, the material passes If the second roll rotates in a direction then the bottom roll rotates in another direction In this type of rolling mill, there are two 1 Two High Rolling Mills It contains two heavy rolls fixed one over the other The rolls are supported in bearing housed in sturdy upright frames (called stands) which are grouted to the rolling mill floor The vertical gap between the roll is adjustable The Rolling Mills: 6 Different Types of Rolling Mills [Images During the course of my 25yearlong experience of endless discussions about rolls, roll application and roll failures with customers and fellow colleagues from other roll producers I found my performance often miserable or worse, frequently due to a lack of common understanding of the basic material science of my subjectA BASIC UNDERSTANDING OF THE MECHANICS OF

Practical Roll Techniques Grinding Balancing

As an integral part of a modern roll maintenance program, roll grinding and balancing uses machinery with accurate inspection and measurement equipment This paper provides practical tips on roll inspections, balancing, grinding and grooving In addition, we discuss proper roll handling during removal, storage, transport, and reinstallation Many shapes and sections are possible to roll by the steel rolling process The difficulty in the removal of the heat from the roll is the result of two factors The goal of mill and the PROCESS OF ROLLING MILLS LinkedInthe mixing Process of the two roll mill Two roll mill in the mixing process relies mainly on two opposite rotation of the roller on the rubber 2017/08/27 Two roll mill Specifications Two moll mill specifications with the "roller working part diameter × roller working part length" to Lab Mill Lab two roll mill Two roll mill Roll mill

Simulation of a TwoRoll Straightening Process and

Tworoll straightening process in a roll mill was simulated by large commercial finite element software The change of stress in tworoll straightening process and the distribution of residual stress after straightening was revealed The surface residual stress of bar A laboratory tworoll mill is used to handprocess plastics and the like It looks like an old fashioned "wringer" from a washing machine mounted horizontally, but it isn't The rolls counterrotate, to be sure, but they do so at different rates to create a shearing action in the trough formed between them"Tworoll Mill" "Poiesis Research, Inc"Rolling is the deformation process of a metal that is widely used in the metal forming process in opposite directions In this mill, between the first and the second rolls, the material passes If the second roll rotates in a direction then the bottom roll rotates in another direction In this type of rolling mill, there are two Rolling Process: Working, Application, Defects, Type of

[PDF] Simulation of a TwoRoll Straightening Process

Residual stress was an important factor for subsequent machining accuracy of bar Tworoll straightening process in a roll mill was simulated by large commercial finite element software The change of stress in tworoll straightening process and the distribution of residual stress after straightening was revealed The surface residual stress of bar after straightening was tested by blindhole Two Roll Rubber Mill sizes from 110 to 200 mm Models : LRMRS110, 150, 200 / Oil or Water Bench Top Two Roll Mill Type Model : LRMM100 The Micro Scientific Bench Top Two Roll Mills type LRMM100 is intended mainly for learning institutes and for laboratories where a LabTech Two Roll Mills Midwestlabtech1 Two High Rolling Mills It contains two heavy rolls fixed one over the other The rolls are supported in bearing housed in sturdy upright frames (called stands) which are grouted to the rolling mill floor The vertical gap between the roll is adjustable The rolls rotate in opposite directions and are driven by electrical motorsRolling Mills: 6 Different Types of Rolling Mills [Images

A BASIC UNDERSTANDING OF THE MECHANICS OF

During the course of my 25yearlong experience of endless discussions about rolls, roll application and roll failures with customers and fellow colleagues from other roll producers I found my performance often miserable or worse, frequently due to a lack of common understanding of the basic material science of my subject Lunn bar, fitted parallel to the mill rolls and positioned so that the operator works over it The Lunn bar has proved effective in reducing the number of fata l and serious maiming injuries at two roll mills from their historical level of about 20 per year in the 1950s 60s, Operators drawn towards the nip will move the trip barIntroduction to rubber processing and safety issues Many shapes and sections are possible to roll by the steel rolling process The difficulty in the removal of the heat from the roll is the result of two factors The goal of mill and the PROCESS OF ROLLING MILLS LinkedIn

Lab Mill Lab two roll mill Two roll mill Roll mill

the mixing Process of the two roll mill Two roll mill in the mixing process relies mainly on two opposite rotation of the roller on the rubber 2017/08/27 Two roll mill Specifications Two moll mill specifications with the "roller working part diameter × roller working part length" to Rolling is the deformation process of a metal that is widely used in the metal forming process in opposite directions In this mill, between the first and the second rolls, the material passes If the second roll rotates in a direction then the bottom roll rotates in another direction In this type of rolling mill, there are two Rolling Process: Working, Application, Defects, Type of cluster mill diagram The cluster mills consist of two working rolls with small diameter and four or more backup roll with larger diameter The number of back up rolls high as 20 or more depends upon the support heeded for the working roll It cluster mill is used for cold rolling process Application of rolling process:rolling operation or roll mill its types and application

Types Of Rolling Process In Manufacturing Industry

A rolling mill is a complex machine having two or more supporting rollers, working rollers, drive motor, roll stands, working rollers, coupling gear, flywheel, etc According to the requirement of the process and technical issues, these rolling machines are available in different shapes and sizes Each rolling mill consists of a minimum of two Product Performance of Lab Two Roll Mill: * Steel roller is driven by a branded motor and the speed control is stable * The surface of the steel roller is plated with hard chrome and mirror polished * Protective cover automatic shutdown protection device * The scope of work can be adjustedLab Two Roll MillLab two roll mill1 Two High Rolling Mills It contains two heavy rolls fixed one over the other The rolls are supported in bearing housed in sturdy upright frames (called stands) which are grouted to the rolling mill floor The vertical gap between the roll is adjustable The rolls rotate in opposite directions and are driven by electrical motorsRolling Mills: 6 Different Types of Rolling Mills [Images

What are main Types of Rolling mill? mech4study

Rolling mills are used to perform rolling process These machines are available in different shapes and size according to requirement of the process and due to technical issues Every rolling mill consist minimum two rolls These numbers can extend according to the process requirementUsed Stewart Bolling 6" x 12" Pilot Two Roll Mill Approximate 6" diameter x 12" long chrome cored rolls Driven by 5 hp, 3/60/220/440 volt gear motor, single speed, fixed gear ratio Unit has front and back knee safeties, and over the roll safety cage Two point manual adjustment, split end guides Serial# 2560Used 2 Roll Mills Buy Sell Used MillsUsed Farrel two roll mill, 60" wide x 22" diameter rolls, cored rolls, unitized base, 150 HP 480 Volt AC 450 RPM motor, 1515576:1 ratio Hansen gearbox rated to 222 HP max with a 15 service factor, 15 hp hydraulic unit, Farrel serial# 79A117122" X 60" Farrel Two Roll Mill Federal Equipment