عنا

مرحبا هل يمكنني مساعدتك؟

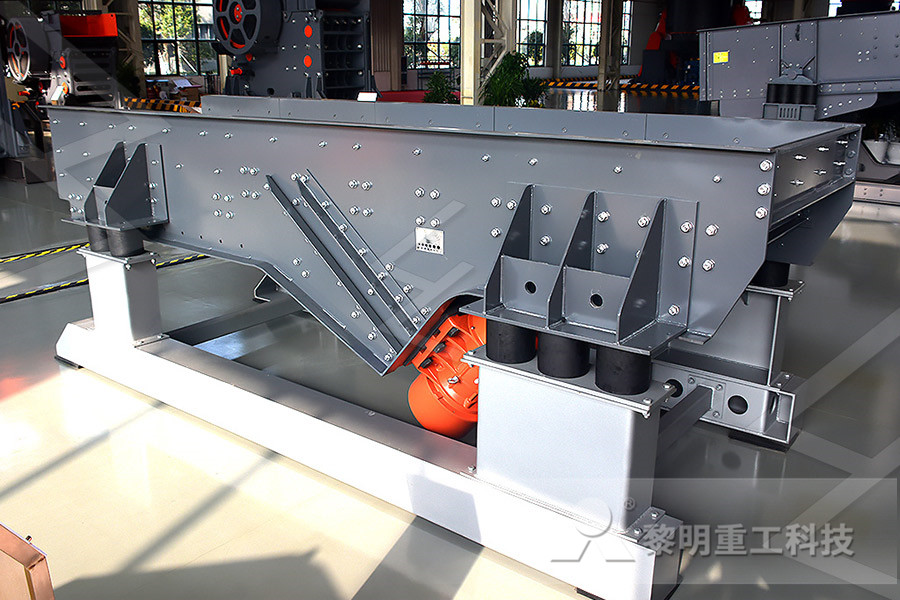

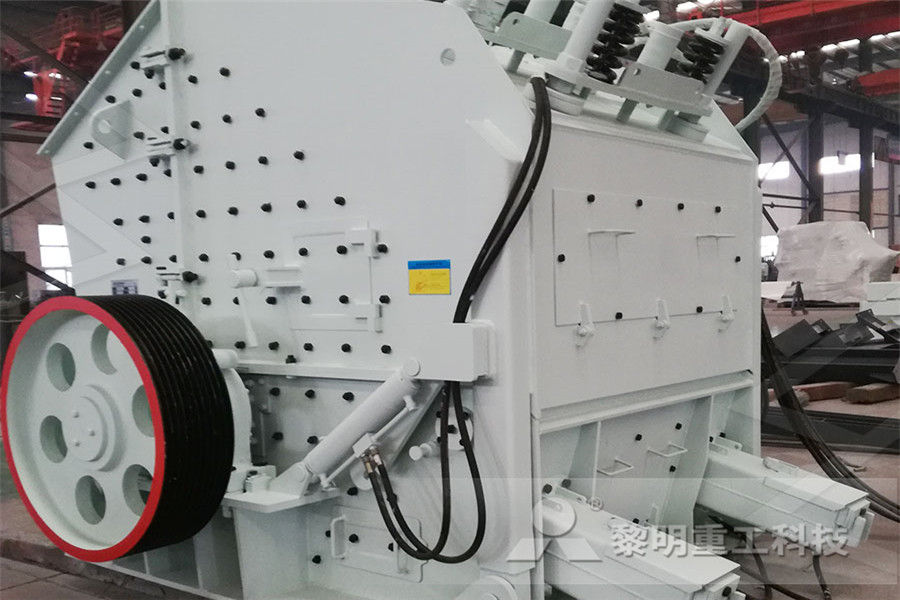

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

what is the cement mill

2021-07-31T12:07:16+00:00

What is a Cement Mill? (with pictures) wiseGEEK

A cement mill is used to make clinkers, which are key in many types of concrete The chief constituent of Portland cement is a sintering product of limestone and aluminosilicate known as clinker This hard, pebble like material is the ingredient in cement which causes it to “cure” and harden to form the mortar or concrete used so extensively in construction This mill is widely used in cement, silicate products, new building materials, refractory materials, fertilizer, black and nonferrous metal processing , glass ceramics production, and the other industries The mill components: 1 CylinderComponents Introduction of the Cement Mill kara liu 博客园Cement grinding Vertical roller mills versus ball mills patent and started selling an improved version of this mill all over the world For the cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grindingwhat is cement mill bossuytgrootkeukenbe

Cement Vertical Mill Vertical Grinding Mill Vertical

The cement vertical mill is a grinding equipment developed on the basis of similar grinding mills, so it has many irreplaceable advantages, such as high grinding efficiency, low power consumption (2030% less power than ball mill), large drying capacity (simultaneously dry and grind materials with moisture up to 10%), large particle size of grinding materials, simple grinding process, small cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grindingCement grinding Vertical roller mills versus ball millscement mill increase capacity cement mill increase capacity Cement mill Wikipedia OverviewHistoryMaterials groundTemperature controlBall MillsRoller millsHighpressure roll pressesCapacity of cement mills A cement mill (or finish mill in What Is Capacity Of Cement Mill restaurant

What Is The Cost Of Cement Mill Gasthof Rosenthal

The Cost Of Cement Mill fstechniek cost of cement mill azdoc what is cost of cement mill Cement mill Wikipedia A cement mill or finish mill in North American usage is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective Cement Manufacturing – A Wet Process with Flow CEMENT MANUFACTURING – A WET PROCESS WITH THE FLOW DIAGRAM Advantages: Raw material can be mixed easily, so a better homogeneous material can be obtained Capital cost (Cost of establishment) is comparatively less Disadvantages: Mixing of Raw materials in wash mill what is wash mill cement manufacture A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

Cement Roller Press Roller Press In Cement Plant

The cement roller press has a high energy utilization rate and remarkable energysaving effect in the material grinding process In cement plant, cement roller press is a kind of important cement equipment used for clinker grinding It is usually combined with a cement ball mill to form a highefficiency cement grinding system because the practice shows that the grinding process with small It is known that cement mill is the key equipment used to recrush the materials This mill is widely used in cement, silicate products, new building materials, refractory materials, fertilizer, black and nonferrous metal processing , glass ceramicsComponents Introduction of the Cement Mill kara liu 博客园The cement ball mill is a kind of cement grinding mill It is mainly used for grinding the clinker and raw materials of the cement plant, and also for grinding various ores in metallurgical, chemical and electric power enterprises It has the characteristics of strong adaptability to materials, continuous production, large crushing ratio and Cement Ball Mill Cement Grinding Machine

Raw Mill In Cement Plant,Cement Making Plant

The cement is delivered to endusers either in bags or as bulk powder blown from a pressure vehicle into the customer's silo In industrial countries, 80% or more of cement is delivered in bulk Our raw mill has been widely used in the cement making plant In a large number of customer feedback, we received a lot of enthusiasm and positive Ball Mill Cement 207 2003 Abyek Cement Iran Ball Mill Cement 315 2004 Holcim (Lanka) Sri Lanka Roll Press Dept Cement 330 2004 Kordestan Cement Iran Ball Mill Cement 595 2007 Mustehkam Cement Pakistan Cement 766 2010 Hu Nan Shaofeng China MLS3626 LV Classifier Cement 765 2010 NSCICement Mill 4 Malaysia CementCement Mill :: LV TECHNOLOGYCement mill 发布时间: 2015 11 30 Product purpose:Used for producing the cement clinker Technical features: 1It is suitable for different material grinding system, used with roller presser, can greatly increase production capacity and reduce the power consumption 2The equipment is stable and reliable, high operation rate, low maintenance costCement mill Tube Mill

Review on vertical roller mill in cement industry its

The cement mill is either a Ball mill with two chambers or Vertical roller mill with inbuilt classifier Material is ground till desired Blaine is achieved and then final product is stored in concrete silos for further blending In silos cement is stored separately according to their grades so that mixing doesn't happen , , , Cement extracted J M Gears Engineering Offering Cement Mill, सीमेंट कारख़ाना, New Items in Gudli, Udaipur, Rajasthan Read about company Get contact details and address ID: Cement Mill, सीमेंट कारख़ाना in Gudli, Udaipur , The OK™ mill has been ’s standard cement VRM since 1993 Since its introduction, the OK mill has proven to be the most efficient cement VRM available, with the highest reliability and ease of operation In 2017, introduced the OK raw mill, which is designed with the same proven technology and modular design as the OK cement OK™ mill The most reliable and efficient mill for raw and

Schwenk invests in cement mill and multichamber silo

Depending on the type of cement, the mill will have a capacity of up to 170tph and will partly replace existing more energyintensive mills The mill will be supplied by Christian Pfeiffer Maschinenfabrik GmbH, Germany The multichamber silo will be 60m high and have a capacity of 12,500t Cement Production Line In cement production line, rotary kiln, ball mill is the indispensable equipment rotary kiln and ball mill production by Henan Zhengzhou Mining Machinery Co, Ltd can improve the efficiency of the cement production, saving energy,help you get more economic interestsBall MillCement MillCement Kilngrind millrod mill The cement is delivered to endusers either in bags or as bulk powder blown from a pressure vehicle into the customer's silo In industrial countries, 80% or more of cement is delivered in bulk Our raw mill has been widely used in the cement making plant In a large number of customer feedback, we received a lot of enthusiasm and positive Raw Mill In Cement Plant,Cement Making Plant

Operation Guide for Vertical Roller Mill in Cement

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etcCement mill 发布时间: 2015 11 30 Product purpose:Used for producing the cement clinker Technical features: 1It is suitable for different material grinding system, used with roller presser, can greatly increase production capacity and reduce the power consumption 2The equipment is stable and reliable, high operation rate, low maintenance costCement mill Tube Mill The cement mill is either a Ball mill with two chambers or Vertical roller mill with inbuilt classifier Material is ground till desired Blaine is achieved and then final product is stored in concrete silos for further blending In silos cement is stored separately according to their grades so that mixing doesn't happen , , , Cement extracted Review on vertical roller mill in cement industry its

Cement Mill, सीमेंट कारख़ाना in Gudli, Udaipur ,

J M Gears Engineering Offering Cement Mill, सीमेंट कारख़ाना, New Items in Gudli, Udaipur, Rajasthan Read about company Get contact details and address ID: Cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Read More Exhibition Special Coverage More We sincerely invite you to participate La We sincerely invite you to participate La GGBSCement Plant,cement grinding mill,vertical Cement Production Line In cement production line, rotary kiln, ball mill is the indispensable equipment rotary kiln and ball mill production by Henan Zhengzhou Mining Machinery Co, Ltd can improve the efficiency of the cement production, saving energy,help you get more economic interestsBall MillCement MillCement Kilngrind millrod mill

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

The mill is designed to handle a total ball charge of 3245 t at 100% loading with a percentage filling of 295% in both the chambers Both the chambers of the cement mill were charged with 80% of the designed charge, which works out to 86 t in Ist chamber and 172 t in the IInd chamberPfeiffer is going to equip a grinding plant of Chettinad Cement Corp Pvt Ltd with an MVR 6000 C6 roller mill Gebr Pfeiffer supplied almost 150 MPS and MVR mills to India, with customers headquartered in Delhi, Mumbai, Kolkata, Hyderabad, Ahmedabad and Pfeiffer MVR cement mill for Southern IndiaThe MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements The MPS vertical roller mill built to last, reliable and energyefficient is the optimum solution when it comes to performing several process steps in one unitCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills