عنا

مرحبا هل يمكنني مساعدتك؟

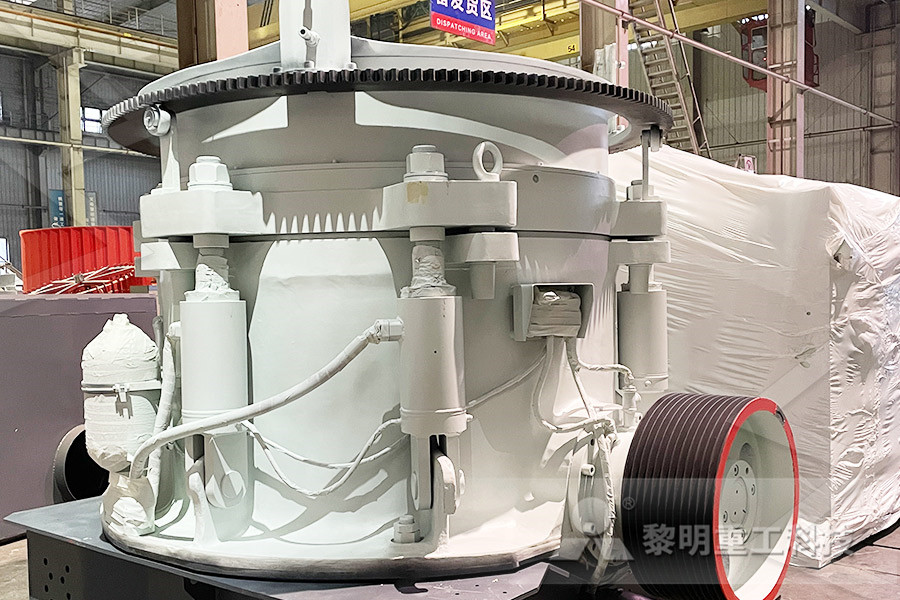

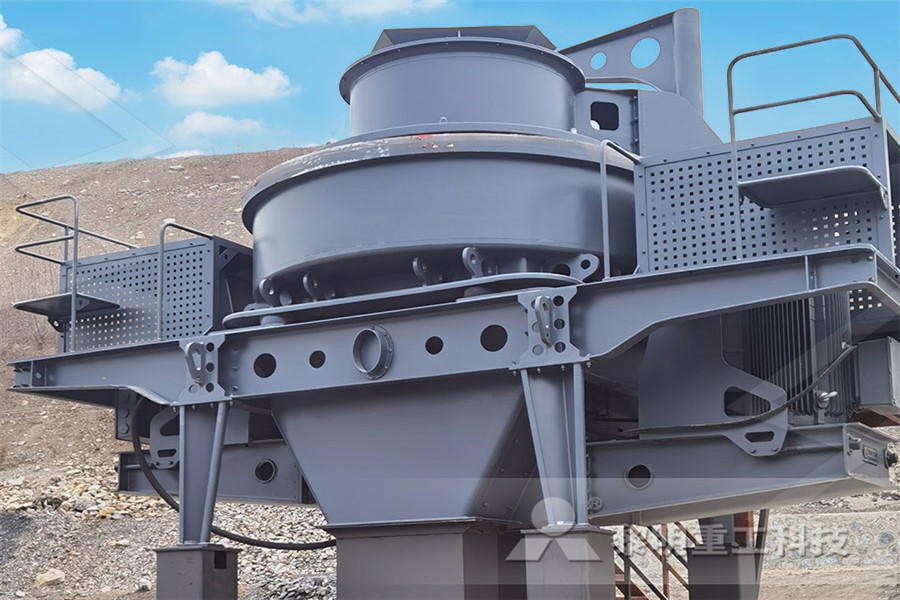

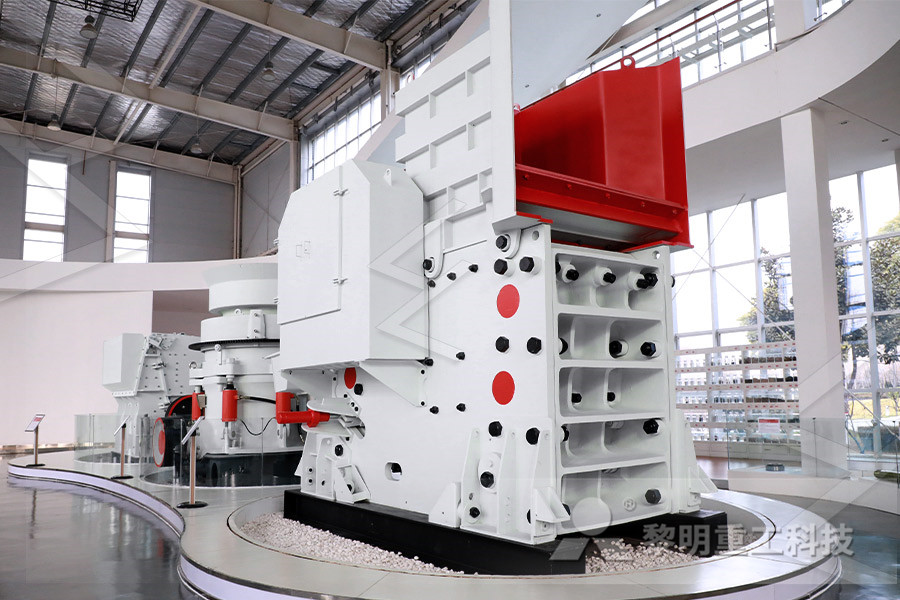

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

grinding of manufacture of cement

2022-06-02T17:06:06+00:00

The process of manufacture of cement consists of

The process of manufacture of cement consists of grinding the raw materials finely, mixing them thoroughly in certain proportions, and then heating them to about 1480 ° C in huge cylindrical steel rotary kilns 37–10 m in diameter and 50–150 m long and lined with special firebrick (The rotary kilns are inclined from the horizontal by about 3 ° and rotate on its longitudinal axis at a The cement grinding aids is additional material in liquid or solid form admixed in small amount during the cement clinker grinding process which can significantly improve the grinding efficiency and reduce energy consumption without compromising the performance of the cement The cement grinding is an energy intensive process The addition ofcost of grinding process in cement manufacture Cement manufacturing process what is cement made of, it can be discussed conveniently under two headings: Selection of Raw materials and manufacturing methods Raw Materials of Cement Most important raw materials (what is cement made of) required in the manufacture of Portland Cement Cement Manufacturing Process: What is Cement

ELEMENTAL CHEMISTRY: Manufacture of Cement

The essentials raw materials for the manufacture of cement are limestone and clay which supply all the four principal ingredients, such as CaO, Al 2 O 3, SiO 2, and Fe 2 O 3 Calcium oxide and iron oxide, these both substance are obtained from limestone, while silica and alumina are obtained from the clay Thus raw materials are two types Cement is delivered to consumers in automobiles and railway cement tanks in bulk, or in paper multilayer bags Fig (34) Dry Process The dry process for the manufacture of cement is preferred only in places where hard crystalline limestone Explain dry and wet process of cement manufacturing The entire manufacture of portland cement process in a modern plant is now control through a microprocessor base programmable logic control system to maintain a consistently uniform quality of cement and a high rate of production The entire operation of the plant is control centrally in a single control room and the plant employs minimum of manpower as compare to previous plants construct Manufacture of Portland Cement Process and

Cement Manufacturing Process Civil Engineering

In cement manufacture it is prime raw material and its usage would be 90 93% (2) Clay : It contains more of silica (SiO2) and its usage should be 2 to 3% in cement manufacture (3) Bauxite : It contains alumina (Al2O3) and it’s usage should be 2 to 3% in cement manufacture The flow diagram of cement manufacture is given below: Coal Requirement: In dry process 100 kg coal is required per ton of cement, while in wet process 350 kg coal is required for the same quantity of cement In 1998 there were 173 large cement plants in IndiaManufacture of Portland Cement: 3 Processes Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln In this process, the chemical bonds of the raw materials are broken down and then they are The Cement Manufacturing Process Advancing Mining

Manufacture Of Cement Grinding Unit

manufacture of cement grinding unit A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are The cement grinding aids is additional material in liquid or solid form admixed in small amount during the cement clinker grinding process which can significantly improve the grinding efficiency and reduce energy consumption without compromising the performance of the cement The cement grinding is an energy intensive process The addition ofcost of grinding process in cement manufacture Stage of Cement Manufacture There are six main stages of cement manufacturing process Stage 1 Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite The ore rocks are quarried and crushed to smaller pieces of about 6 inchesCement Manufacturing Process Civil Engineering

ELEMENTAL CHEMISTRY: Manufacture of Cement

The essentials raw materials for the manufacture of cement are limestone and clay which supply all the four principal ingredients, such as CaO, Al 2 O 3, SiO 2, and Fe 2 O 3 Calcium oxide and iron oxide, these both substance are obtained from limestone, while silica and alumina are obtained from the clay Thus raw materials are two types Cement is delivered to consumers in automobiles and railway cement tanks in bulk, or in paper multilayer bags Fig (34) Dry Process The dry process for the manufacture of cement is preferred only in places where hard crystalline limestone and shales are availableExplain dry and wet process of cement manufacturingIn cement manufacture it is prime raw material and its usage would be 90 93% (2) Clay : It contains more of silica (SiO2) and its usage should be 2 to 3% in cement manufacture (3) Bauxite : It contains alumina (Al2O3) and it’s usage should be 2 to 3% in cement manufactureCement Manufacturing Process Civil Engineering

Cement Extraction and processing Britannica

Cement Cement Extraction and processing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be dug directly by excavatorsCement, in general, adhesive substances of all kinds, but, in a narrower sense, the binding materials used in building and civil engineering construction Cements of this kind are finely ground powders that, when mixed with water, set to a hard massSetting and hardening result from hydration, which is a chemical combination of the cement compounds with water that yields submicroscopic cement Definition, Composition, Manufacture, Thamesport Cement has submitted a full planning application of its proposed site on the Isle of Grain, Kent, UK Backed by Francebased Cem’In’Eu, the company promises to bring “21st century cement manufacturing” to the UKThamesport Cement to build 05Mta grinding plant in

The process of manufacture of cement consists of

The process of manufacture of cement consists of grinding the raw materials finely, mixing them thoroughly in certain proportions, and then heating them to about 1480 ° C in huge cylindrical steel rotary kilns 37–10 m in diameter and 50–150 m long and lined with special firebrick (The rotary kilns are inclined from the horizontal by about 3 ° and rotate on its longitudinal axis at a The cement grinding aids is additional material in liquid or solid form admixed in small amount during the cement clinker grinding process which can significantly improve the grinding efficiency and reduce energy consumption without compromising the performance of the cement The cement grinding is an energy intensive process The addition ofcost of grinding process in cement manufacture2 天前 The manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and burning them to sintering in a kiln at a temperature of about 1350 to 1500 ⁰C During this process, these materials partially fuse to form nodular shaped clinker by broking of chemical Manufacturing of Portland Cement – Process and

types of grinding in cement manufacture

types of grinding in cement manufacture Cement mill Wikipedia, the free encyclopedia The emergence of Portland cement in the 1840s made grinding considerably more of specialized steel led to the development of new forms of grinding equipment, and The cement mills on a cement plant are usually sized for a clinker The essentials raw materials for the manufacture of cement are limestone and clay which supply all the four principal ingredients, such as CaO, Al 2 O 3, SiO 2, and Fe 2 O 3 Calcium oxide and iron oxide, these both substance are obtained from limestone, while silica and alumina are obtained from the clay Thus raw materials are two typesELEMENTAL CHEMISTRY: Manufacture of Cement PORTLAND CEMENT • Portland cement is the most common type of cement in general used around the world as a basic ingredient of concrete and mortar • It is a fine powder, produced by heating limestone and clay minerals in a kiln to form clinker, grinding the clinker, and adding small amounts of other materialsManufacturing of cement SlideShare

Manufacturing process Lafarge Cement, concrete

2 天前 The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km Cement is delivered to consumers in automobiles and railway cement tanks in bulk, or in paper multilayer bags Fig (34) Dry Process The dry process for the manufacture of cement is preferred only in places where hard crystalline limestone and shales are availableExplain dry and wet process of cement manufacturing The cement industry is particularly reliant upon particle size reduction Raw materials crushing and grinding seeks to reduce materials from roughly one meter cubes of blasted stone to a size where at least 80 percent of the raw material is less than 75 microns Finish grinding of clinker and other cementBreakthrough in Clinker Grinding

Thamesport Cement to build 05Mta grinding plant in

Using horizontal grinding mill technology, the plants are capable of producing up to 250,000tpa of cement Representing a significantlylarger investment, the proposed facility at Thamesport will have two mills and be capable of producing up to 485,000tpa