عنا

مرحبا هل يمكنني مساعدتك؟

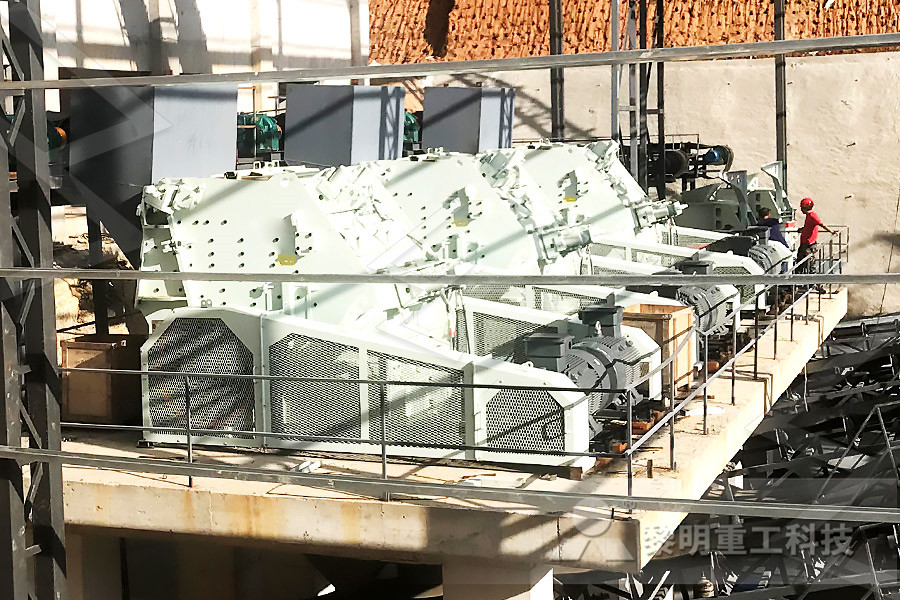

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

sand for foundry mold

2022-06-14T17:06:40+00:00

Introduction to Foundry Sand American Foundry

2 天前 What is foundry sand? Most metalcasting sand (FS) is high quality silica sand with uniform physical characteristics It is a byproduct of the ferrous and nonferrous metal casting industry, where sand has been used for centuries as a molding material because of its unique engineering properties Foundry sand is clean, uniformly sized, high quality silica sand, used in foundry casting processes The sand is bonded to form molds or patterns used for ferrous (iron and steel) and nonferrous (copper, aluminum, brass) metal castings Shakeout sand from completed metal casting are often reclaimed back into the foundry sand processWhat is foundry sand? Solex Sand casting is a metalworking process in foundry that uses sand as the molding material, allowing for lowcost casting of unique metal shapes Sand casting molds are the indispensable parts in the sand casting process and play the vital role in casting a range of industry applicationsInstructions for Making Sand Casting Molds in detail

FOUNDRY SAND COMPOSITION FOR CORES AND

A foundry sand composition for cores and molds comprising a wet mixture of foundry sand, and the following components based on 100 parts by weight of said foundry sand: 2 to 5 parts of an aqueous resin consisting essentially of (a) the reaction product of phenol and formaldehyde wherein the molar proportion to formaldehyde is 1:18 to 1:30 and the pH is more than 10, or (b) the reaction product of Sand cutters that operate over a heap on the foundry floor may be used instead of mullers Delivery of the sand to the molding floor may be by means of dump or scoop trucks or by belt conveyors During the process of casting, the sand is formed into Foundry Sand: Life of a Casting Reliance Foundry The sand mold is in an uncured state as the metal is being poured Sand casting using green sand is quick and inexpensive since the sand can be reused The downside is that the sand is a soft mold and can collapse or shift during casting, The 3 Types of Sand Used for Sand Casting Patriot

Sand Casting Reliance Foundry Co Ltd

Sand molds can be formed to create castings with fine exterior detail, inner cores, and other shapes Nearly any metal alloy can be sand cast Hollows are made in moistened sand, filled with molten metal, and left to cool What is Molding Sand? EZ Kote™ 65 Foundry Core and Mold Coating Foundry Core and Mold Coating for Green Sand Metalcasting Foundry Hill and Griffith EZ KOTE™ core and mold coating are water based refractory coating formulated for ferrous and nonferrous castings The formulation permits the product to be used on small intricate cores up to heavy cores and moldsEZ KOTE™ 65 Green Sand Metalcasting Foundry Core Place the mold cavity shell—without the wall—into a flask (the reinforcement tooling, typically boxshaped, used to contain molds in foundry casting) and pack it with foundry Foundry Says Robotic Sand Printing a “Game

Ceramic Molding Sand Foundry Sand Midvale

Ceramic Molding Core Sand Improve your casting quality by using a Silica Free Ceramic Mold and Core Sand This ceramic sand is made from bauxite base material which creates hard particles and will last longer than other ceramic media on the market Available in multiple sizes including AFS 55, 70 and 80 Major BenefitsAdditive manufacturing of sand molds for metalcasting may implement any of the same foundry sands as green sand processes, but uses a furan binder instead of the traditional mixture of bentonite Thermal Properties of Foundry Mould Made of Used The first step is to create the mold for the casting A sand mold is formed by packing sand into each half of the mold (learn more about types of sand used in sand casting) The sand is packed around the pattern, which is a replica of the external shape of the casting When the pattern is removed, the cavity that will form the casting remains Foundry Sand Casting Process: Simple Step by Step

Foundry casting Foundry steps Foundry Sand

Sand foundry is the oldest and most commonly used method for the foundry of aluminum, steel and other metals and has a low investment advantage with flexible casting design, a wide selection of alloys and easy design change In this method of foundry, a piece in Sand foundry mold is formedChina Foundry Casting Sand manufacturers Select 2021 high quality Foundry Casting Sand products in best price from certified Chinese Green Sand Casting Foundry manufacturers, Casting Item suppliers, wholesalers and factory on MadeinChinaChina Foundry Casting Sand, Foundry Casting Sand Sand casting, or sand mold casting, is a popular method of producing nonferrous alloy casts Invented over 6,000 years ago, this process has undergone a number of changes and modernizations over the years, but the basic principals have remained the sameThe 3 Types of Sand Used for Sand Casting Patriot

Mold Seal Green Sand Casting Foundry Sealant

Foundry Sealant for Green Sand Metalcasting Foundry Hill and Griffith MOLD SEAL is a unique compound that is specifically designed for use in a high production molding environment APPLICATION MOLD SEAL is a low viscosity material that can be used in a handsqueeze bottle Contains no asbestos; Nonsilica based material; Seals rapidly with minimum time and effortLarge Antique Foundry Pattern Sand Mold, Park Garden Bench Legs, Ends, 4' x 38" $35000 Local Pickup 15 watching Antique Industrial Foundry Wood Sand Cast Mold Pattern Boat 90 Stantion Parts $7500 $4020 shipping or Best Offer 25” INDUSTRIAL FOUNDRY VALVE GEAR, Atq Vtg Wood Mold Pattern Wheel Wall Art $26500Foundry Mold for sale eBaySAND MOLD CASTINGS The practice of sand casting involves the use of sand as a mold material to perform metal casting The process is one of the most ancient methods used in manufacturing metal parts and items Nowadays, sand casting remains one of the most widely employed casting techniques Several reasons account for the popularity of sand Sand Mold Castings – Custom Machined, Forged, Cast

Foundry K H Precision

The Sand Mold casting process is an ageold process in its purest state Over the years it has morphed in several directions At KH we use fine nobake sand and a urethane binder giving us the ability to expand to a broader range of possibility in process typical partsUsed foundry sand (UFS) (Fig 41) is a discarded material coming from ferrous (iron and steel) and nonferrous (copper, aluminium, and brass) metalcasting industry to create molds and cores About 1 ton of foundry sand for each ton of iron or steel casting produced is used (Siddique and Noumowec, 2008) Typically, suppliers of the automotive Foundry Sand an overview ScienceDirect Topics The flowsheet shown in this study is particularly adapted to the requirements of the average foundry to reclaim foundry sand for reuse Any foundry whose new sand delivered costs is too high should seriously consider reclamation with the flowsheet as illustrated This reclaimed sand is usually equal to, or better than the original sand Foundry sand once used must be thoroughly water scrubbed Recycling Sand from Foundry Casting Molds

Thermal Properties of Foundry Mould Made of Used

Additive manufacturing of sand molds for metalcasting may implement any of the same foundry sands as green sand processes, but uses a furan binder instead of the traditional mixture of bentonite Ceramic Molding Core Sand Improve your casting quality by using a Silica Free Ceramic Mold and Core Sand This ceramic sand is made from bauxite base material which creates hard particles and will last longer than other ceramic media on the marketCeramic Molding Sand Foundry Sand Midvale The first step is to create the mold for the casting A sand mold is formed by packing sand into each half of the mold (learn more about types of sand used in sand casting) The sand is packed around the pattern, which is a replica of the external shape of the casting When the pattern is removed, the cavity that will form the casting remains Foundry Sand Casting Process: Simple Step by Step

Foundry casting Foundry steps Foundry Sand

Sand foundry is the oldest and most commonly used method for the foundry of aluminum, steel and other metals and has a low investment advantage with flexible casting design, a wide selection of alloys and easy design change In this method of foundry, a piece in Sand foundry mold is formedSand casting, or sand mold casting, is a popular method of producing nonferrous alloy casts Invented over 6,000 years ago, this process has undergone a number of changes and modernizations over the years, but the basic principals have remained the sameThe 3 Types of Sand Used for Sand Casting Patriot We are ALBCO Foundry and Machine For more than 60 years, industries across the country have come to know and trust us for superior quality, service and value Our stateoftheart production facility provides complete foundry capabilities in zincaluminum, graphite mold, ZA12 and copperbased alloy sand ALBCO Foundry Premier NonFerrous Sand

Casting Defects Sand Mold, Metal Casting Iron

Casting Defects Sand Mold, Metal Casting Introducing various metal casting defects with many pictures by Dandong Foundry in China These are the common sand casting defects on the surface and inside of cast iron and cast steel parts 1 Blowhole and Pinhole This is a kind of cavities defect, which is also divided into pinhole and subsurface blowholeOnce the Perlite mixture dries, remove the wooden box halves to reveal the new mold How to build an even larger foundry Note that a larger foundry, suitable for melting large pieces of metal, can be made using a large steel drum and a 5gallon paint bucket The construction process is the same as the method used to build the small foundryHow to build a simple foundry (forge) and mold metal