عنا

مرحبا هل يمكنني مساعدتك؟

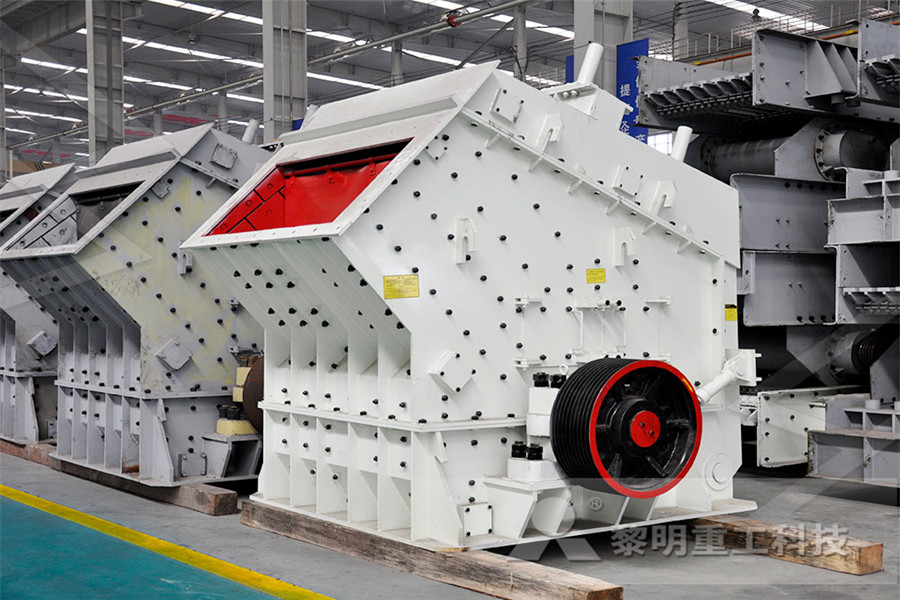

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

roll neck lubrication grinding

2023-05-01T08:05:23+00:00

Lubrication of Roll Neck BearingsFUWEI (LUOYANG

In blooming or shape steel rolling mills with centralized lubrication of the roll neck bearing, the specified amount of grease is supplied at a set interval When the grease filling method is employed as in the case of the roll neck bearing of a cold rolling mill, new grease is added until the old grease is pushed out slightly from the seal LUBRICATION ON PLTCM ROLL BEARINGS AND ROLL NECK QUAKERTEK™ CS 4602EP THE PRODUCT QUAKERTEK™ CS 4602EP is a unique lubricating grease that utilize an entirely new approach in thickener technology It provides exceptional lubricity, thermal stability, rust protection, and water washout resistance Its mechanical stability surpassLUBRICATION ON PLTCM ROLL BEARINGS AND ROLL That results in consistently high grinding quality on the roll Thanks to the combination of hydrodynamic and hydrostatic spindle lubrication, Herkules achieves a minimal bearing play for both very high and very low revolutions per minute and thus a precise Roll Grinders Traversing Grinding Saddle Herkules

A case study of the effect of lubrication and profile

Research and tests carried out by National Research Council of Canada, CSX Transportation and Loram Maintenance of Way, led to the development of a comprehensive lubrication and grinding program The lubrication emphasized friction control between the low railwheel interface The grinding method was changed from corrective to preventiveLUBRICATION Timken lubricants reduce friction, reduce wear and protect bearing surfaces from corrosion We offer a wide selection of lubricants, including Timken Mill Grease, which we formulated to perform in the dificult roll neck bearing environment Timken single and multipoint lubricators and lubrication deliveryTIMKEN ENGINEERING MANUAL More Effective Cooling, Lubrication for Grinding Coherentjet nozzles offer advantage over plastic and rigid tube nozzles for coolant delivery to grinding wheels In this example, coherentjet technology uses a combination of round nozzle tubes, collet More Effective Cooling, Lubrication for Grinding

when i roll my neck/shoulders, i feel/hear a cruching

when i roll my neck/shoulders, i feel/hear a cruching/grinding sound, what could this be? 1 doctor answer • 1 doctor weighed in Share Dr Donald Alves answered Emergency Medicine 24 years experience Muscle: It is likely muscle bands / spasms from tension or injury or overuse They rub over one another when rolling neck/shouldersSTATIC AND DYNAMIC BEHAVIOUR OF ROLL GRINDING MACHINES The working accuracy of a roll grinder is determined mainly by the deflexion between grinding wheel and roll at the cutting point These deflexions are dependent on: (a) dimensional accuracy of the grinder and its components; (b) accuracy of assembly; (c) static and dynamic response to static and dynamic forces generated during the cutting Some problems and experiences with roll grinding Crepitus or crepitation is the noise that may be heard during joint movements, such as a cracking, popping, snapping, or grinding These sounds and sensations can occur in the neck as well Most people at some point have experienced neck crepitus One example is feeling a cracking sensation in the neck Neck Cracking and Grinding: What Does It Mean?

Neck Crunching: Causes and Exercises for Relief MD

2 天前 Using your neck muscles, gently press your head forward while resisting this movement with the hands Hold for five seconds Now press your hands against the back of the head Lubrication 51 Purpose and effect 52 Lubrication method 521 Grease lubrication ring that is tightly fitted to the roll neck When a grinding allowance is provided for the inner ring raceway surface and ground together With the roll barrel after fitting to the roll neck, the roll runout can CATNo E9001b 2003 E9 nskFL Improved lubrication stations for grinding rollers Oct 29, 2013 Experience shows that improving the lubrication system of ATOX® mills can further enhance performance Lubrication of roll neck bearings 29 Grease mills To achieve a particularly good running accuracy, cylindrical roller bearings are sufficiently safe Ok Mill Roller Lubrication

Mounting and maintenance instructions Fourrow

Lubrication between the roll neck and inner ring with loose its Finishgrinding the inner rings and the roll body in the same setup allows closer control of bearing internal clearances, improving roll running accuracy and in turn, rolled product quality Should theLUBRICATION Timken lubricants reduce friction, reduce wear and protect bearing surfaces from corrosion We offer a wide selection of lubricants, including Timken Mill Grease, which we formulated to perform in the dificult roll neck bearing environment Timken single and multipoint lubricators and lubrication deliveryTIMKEN ENGINEERING MANUAL (1) Grinding method of roll surface with double row cylindrical roller bearings: The inner ring of cylindrical roller bearing grinding roll surface based on inner ring raceway becomes rigid component on roll neck through interference fit heat installation, and then the geometric precision of grinding roll surface based on raceway surface is Advantages of Modified Doublerow Tapered Roller

AHR International ball bearings roller bearings slewing

326 Cautions for assembly of the roll and chock assembly with the bearing 33 Fourrow cylindrical roller bearing, RV 331 Assembling the bearing into the chock 332 How to install and remove the inner ring 333 Installation onto the roll neck 334 Simultaneous grinding of the roll Some Problems and Experiences with Roll Grinding Machines in Cold Strip Mills 129 Two roll grinders were excited by an electrodynamic vibrator With an excitation force of 20 and 30 Ib resp, the roll grinding machine was excited absolutely at a steady, as shown in Fig 6, and at the wheel head and relatively between roll and wheel headSome problems and experiences with roll grinding Roll Surface Inspection System (RSIS) in operation The WS 1100 Monolith™ grinds backup rolls in chocks Herkules offers a series of grinders with travelling tables that unite a number of technological benefits, such as the possibility to control the grinding process on the flyTraversing grinding saddle Herkules USA

Table of Contents Rolling Mill Bearings

Four Row Cylindricalroller bearings are also popular roll neck bearings providing several benefits First, the inner ring is separable from the outer ring and rollers which allows the inner ring to remain with the roll during grinding processes This assures precise concentricity and negligible runout providing for high rolling accuracy2 天前 Arthritis of the neck orcervical osteoarthritis involves degenerative changes in the joints of the neck These are often due to wearandtear of normal aging As you grow older, the discs between the bones of the neck gradually wear down, lose lubrication, and become stiffNeck Crunching: Causes and Exercises for Relief MD In many rolling processes, the roll grinding process leads to a roll roughness with a pronounced lay, with asperities running along the rolling direction d b the diameter of backup roll neck, L w the halfwidth of work roll barrel, L b the halfwidth of backup roll barrel, F the bending friction, lubrication, heat transfer and roll Rolling Metal an overview ScienceDirect Topics

TIMKEN ENGINEERING MANUAL

LUBRICATION Timken lubricants reduce friction, reduce wear and protect bearing surfaces from corrosion We offer a wide selection of lubricants, including Timken Mill Grease, which we formulated to perform in the dificult roll neck bearing environment Timken single and multipoint lubricators and lubrication delivery 326 Cautions for assembly of the roll and chock assembly with the bearing 33 Fourrow cylindrical roller bearing, RV 331 Assembling the bearing into the chock 332 How to install and remove the inner ring 333 Installation onto the roll neck 334 Simultaneous grinding of the roll AHR International ball bearings roller bearings slewing Circulating oil lubrication :For grinding wheels and gliding surfaces Grinding wheel speed :Max 1000rpm Roll Call :Measuring devices Drives :Main spindle, traverse move, grinding wheels are AC motors, variable speed with frequency control Grinding wheel feed against the roll is manual Crowning :Max 8mm dia difference Dynamic balancing :No Roll Grinder, max 9000mm : Varaoke International Oy

Some problems and experiences with roll grinding

Some Problems and Experiences with Roll Grinding Machines in Cold Strip Mills 129 Two roll grinders were excited by an electrodynamic vibrator With an excitation force of 20 and 30 Ib resp, the roll grinding machine was excited absolutely at a steady, as shown in Fig 6, and at the wheel head and relatively between roll and wheel head Roll neck bearings Conditionsgoverning design 4 Fourrow tapered roller bearingsor a pair ofsphericalroller bearings generallyare loosefitted on a cylindricalrollneck Thusthe chockscan be easilyremoved; however, the field ofapplication of these bearing typesislimited due to the unsuitabilityofloose fitsfor highspeed rollingFAG Rolling Bearings for Rolling Mill Applications Roll Surface Inspection System (RSIS) in operation The WS 1100 Monolith™ grinds backup rolls in chocks Herkules offers a series of grinders with travelling tables that unite a number of technological benefits, such as the possibility to control the grinding process on the flyTraversing grinding saddle Herkules USA

轧机轴承安装维护图文百度文库

轧机轴承安装维护 Mounting and Maintenance of Roll Neck Bearings M Scharting Steel Symposium 2005 Sch “ s F12” Grinding of inner ring and roll body in one setting M Scharting Steel Symposium 2005 φ Dr Schaeffler Group Mounting of Roll Neck Bearings of installation and high performance in demanding roll neck applications Custom designs are available upon request for speciic applications Spherical roller bearings – Spherical roller bearings offer high radial and moderate thrust capacity together with maximum static and dynamic misalignment capabilityTIMKEN METALS PRODUCT CATALOGLoose fit on roll necks and helical groove in the bore In most rolling mill applications, fourrow tapered roller bearings are mounted with a loose fit on the roll neck This enables quick roll changes However, loose fits have the disadvantage that the inner rings turn on their seats under loadDesign considerations SKF