عنا

مرحبا هل يمكنني مساعدتك؟

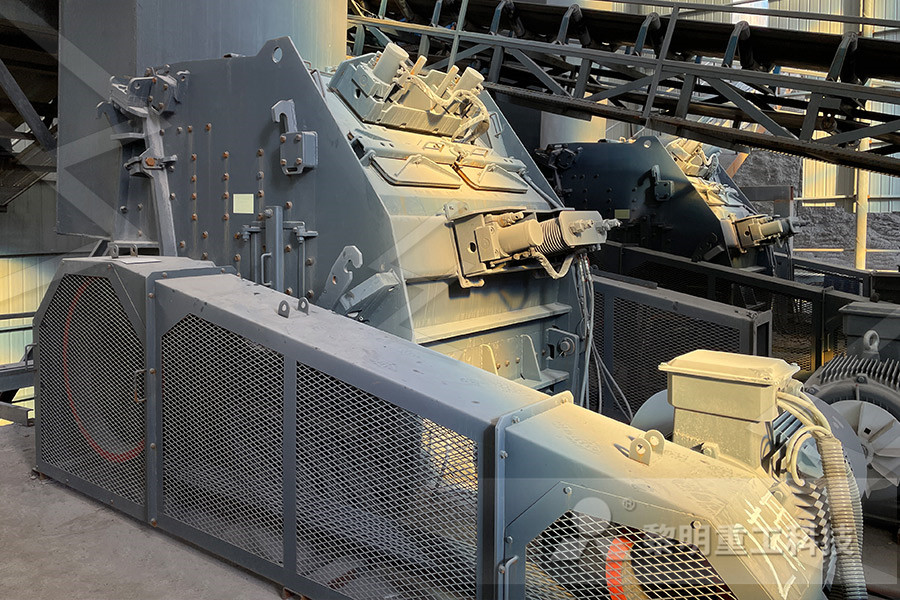

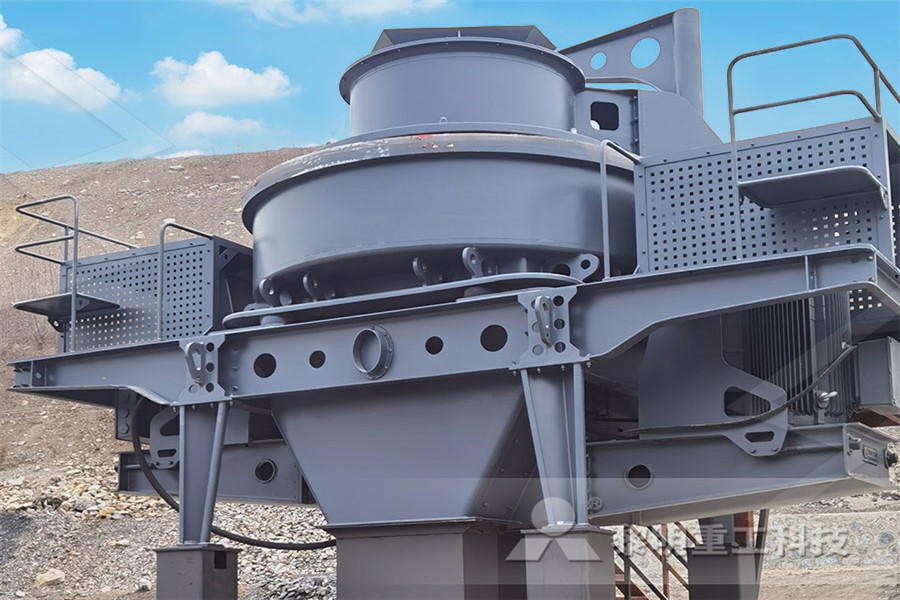

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Brick From Mining Waste

2021-04-11T11:04:55+00:00

(PDF) Utilization of Mining Wastes in Manufacturing

In order to reduce adverse impacts of iron ore wastes, which are mine waste, it is used as aggregate for manufacturing of bricks Mixture was made of iron ore waste; sand and cement with fourWaste Based Brick StoneCycling is engaged in the design, development and manufacturing of building materials from mineral construction waste Depending on the composition, the Waste Based Bricks are available in different colors and textures and are named according to their appearance for example „Wasabi“ or „Salami“Waste Based Brick – Urban Mining and Recycling Malaysian scientists at the Tenaga National University have produced prototype bricks using waste from the mining, coal and steel industries They mixed the materials — including quarry dust, the iron oxide that forms on steel during production, and ash from furnaces — with cement and waterResearchers make bricks from waste, desert sand

Mining Waste Recycling Titan Brick and Block

Mining Waste Recycling Waste from extractive operations (ie waste from extraction and processing of mineral resources) is one of the largest waste streams all around the world It involves materials that must be removed to gain access to the mineral resource, such as topsoil, overburden and waste rock, as well as tailings remaining after minerals have been largely extracted from the oreFurther, building blocks/bricks from mine waste is ecofriendly as it utilizes waste and reduces air, land and water pollution It is energy efficient and also cost effective as reported by various(PDF) Utilisation of mine waste in the construction the firing process This provides a durable color that never transportation, by recycling of process waste, by fades or diminishes reclaiming land where mining has occurred, and by taking • Brick shrink during the manufacturing process as measures to reduce plant emissions Most brick are used vitrification occursManufacturing of Brick

Recycling Of Mining Waste Into Bricks

Anglo American Gypsum turning mining waste into lowcost homes May 26, 2011 Anglo American's Gypsum housing project is turning mining waste into lowcost for the Guardian Sustainable Business waste and recycling award of gypsum a day – mining waste can reduce the cost of brick production due to high silica and calcium oxide contents in gold and limestone mining waste respectively [12,14,15] Thus, utilization of mining waste can(PDF) Incorporation of gold and limestone mining The waste produced from this process – 200 tons of gypsum a day – is being made into bricks to build homes that will enable workers moving away from mine villages to buy affordable homes The plant is the first of its kind in the mining industry, recovering 995% of its water and providing 80,000 people with drinking waterAnglo American Gypsum Turns Mining Waste Into

Bricks and concrete removal

Less waste in our landfills and environmental damage caused by mining is reduced Weight of bricks and concrete By weight, bricks and concrete make up the majority of waste generated from demolition activities Choosing reuse or recycling options can be As a result, there is the potential to use large amounts of waste of suitable composition produced from mining processing as raw materials in the ceramic industry For example, the granite processing industry produces large amounts of waste containing feldspar, quartz, mica, metallic dust and limeProducing Ceramics from Mining WasteThrough an innovative manufacturing process, a real masonry brick is created that’s composed entirely of refuse including materials rescued from landfills, open pit mining byproducts and plant refuse, processed sewage wastes, recycled iron oxides, recycled glass, mineral tailings and other virgin ceramic scrapUsing Waste to Create Newly Potomac Valley Brick

Utilization of Solid Waste from Brick Industry and

The huge amount of solid waste from the brick manufacturing industry can be used as a cement replacement However, replacement exceeding 10% causes a reduction in strength due to the slowing of the pozzolanic reaction Therefore, in this study, the pozzolanic potential of brick waste is enhanced using ultrafine brick powder with hydrated lime (HL) Waste Management Bill (in preparation) Sand mining and brick production at Onambango Village 7 Legislation considered Aspect of Project particles, the proponent should implement the necessary mitigation measures to limit dust emissions to air Public Health Act (Act NoEXISTING SAND MINING BRICK MAKING FACILITY, Key Words: Reuse, waste materials, Brick properties, Industrial waste, Environmental pollution 1 INTRODUCTION Housing is one of the basic requirements for human survival Masonry is an inevitable component of housing Among different types of masonries, brick masonry is one of the mostECOFRIENDLY BRICK CONSTRUCTION USING WASTE

SUSTAINABLE CLAY BRICK PRODUCTION – A CASE STUDY

Brick fired with fossil fuels 700 2,52420 Brick fired with renewable fuels 700 910 The brick fired with renewable fuels features the least energy content of all building products available on the market today 3 2 Land for mining Traditional brick production requires extensive mining operations using land The term “land use” is used to The brick body is quickly hardened after high pressure pressing molding With good utility, the bricks need not be immersed when used in building walls, while the appearance is neat Compared with traditional red brick production, it has the following characteristics: 1 utilizing waste, saving soil and energy 2 Extensive sources of raw Advantages of making brick from construction waste Less waste in our landfills and environmental damage caused by mining is reduced Weight of bricks and concrete By weight, bricks and concrete make up the majority of waste generated from demolition activities Choosing reuse or recycling options can be Bricks and concrete removal

Reuse of mining waste into innovative geopolymeric

Red clay brick and tungsten mining wastebased alkaliactivated binder: Microstructural and mechanical properties Author(s): Naim Sedira, João CastroGomes, Manuel Magrinho Published in: Construction and Building Materials, Issue 190, 2018, Page(s) 10341048, ISSN 09500618 DOI: 101016/jconbuildmat201809153Through an innovative manufacturing process, a real masonry brick is created that’s composed entirely of refuse including materials rescued from landfills, open pit mining byproducts and plant refuse, processed sewage wastes, recycled iron oxides, recycled glass, mineral tailings and other virgin ceramic scrapUsing Waste to Create Newly Potomac Valley BrickAs a result, there is the potential to use large amounts of waste of suitable composition produced from mining processing as raw materials in the ceramic industry For example, the granite processing industry produces large amounts of waste containing feldspar, quartz, mica, metallic dust and limeProducing Ceramics from Mining Waste

Utilization of Solid Waste from Brick Industry and

The huge amount of solid waste from the brick manufacturing industry can be used as a cement replacement However, replacement exceeding 10% causes a reduction in strength due to the slowing of the pozzolanic reaction Therefore, in this study, the pozzolanic potential of brick waste is enhanced using ultrafine brick powder with hydrated lime (HL)Our range of specialty products have been developed in house targeted directly at the many unique problems that Brick Cleaners Mining AGent Sales Services has enjoyed a long, productive relationship with the Western Australian mining sectorBrick Cleaning Company Mining Industry Western of brick is reduced compare with nominal brick Efflorescence values were low than the normal brick The bricks are likely to add energy efficiency in buildings and help create economic value to manufacturers, thereby, encouraging the ecosystem of plastic waste management involving all actors in Study of Plastic Bricks Made From Waste Plastic

SUSTAINABLE CLAY BRICK PRODUCTION – A CASE STUDY

Brick fired with fossil fuels 700 2,52420 Brick fired with renewable fuels 700 910 The brick fired with renewable fuels features the least energy content of all building products available on the market today 3 2 Land for mining Traditional brick production requires extensive mining operations using land The term “land use” is used to Turkey has lowcalorie coal deposits and excessive BA resulting from its use We address the reusing of this waste through beneficial recovery mechanisms The manuscript reports successful fired brick production from C NKR substituted with BA GFCNF (0, 10, 20, 30 and 40%) byEcoFriendly Fired Brick Produced from Industrial Ash