عنا

مرحبا هل يمكنني مساعدتك؟

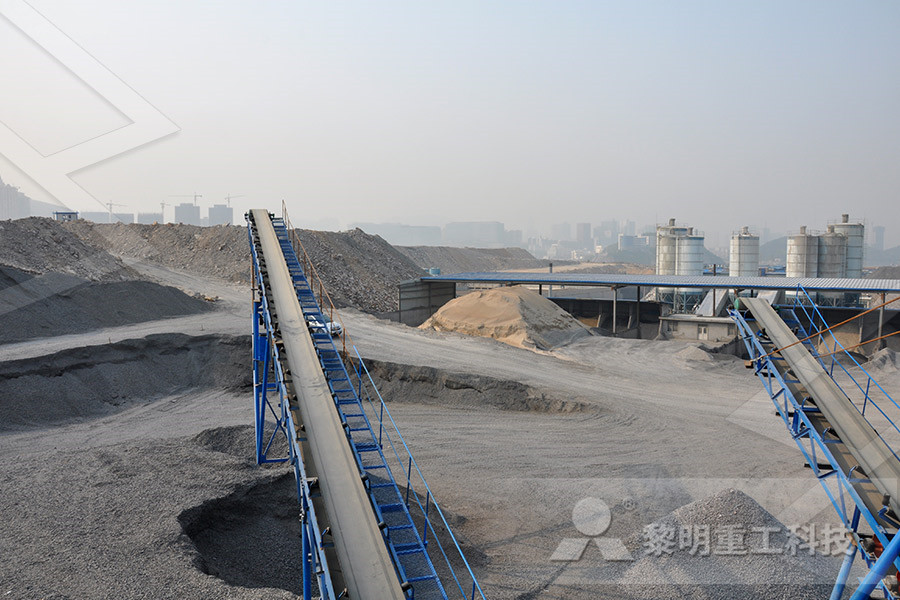

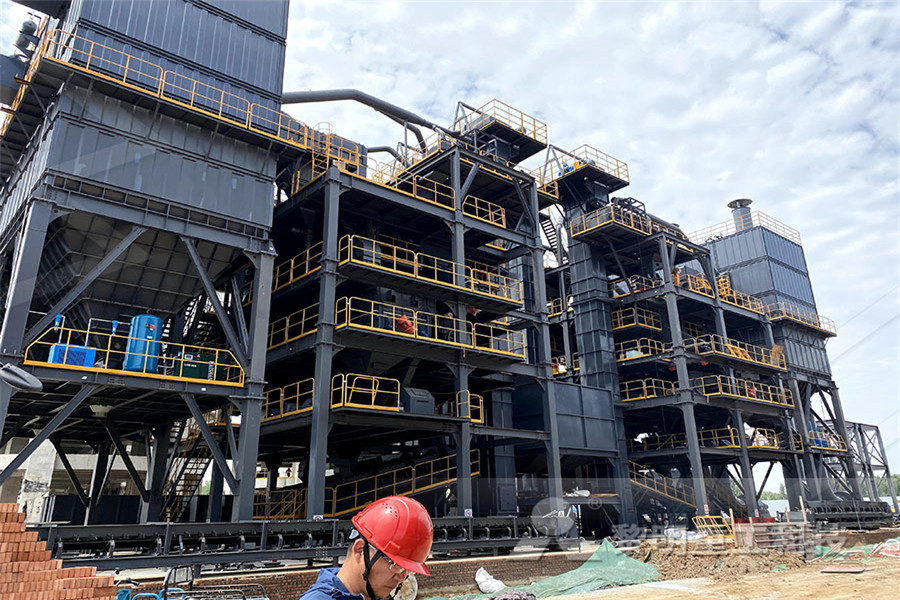

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

limestone desulfurization equipment

2019-09-17T08:09:37+00:00

limestone desulfurization, limestone desulfurization

Wet desulfurization process limestone circulating slurry pump for power plant US $21000 $21000 / Set Innovations: firstly, the limestone powder aerodynamic field will be optimized, include the situation, angle and speed of jet to make mix fully so that improve the desulfurization efficiency Secondly, that is the steam return, it means that ash from high temperature separator on boiler exit and desulfurizer return to furnace by steam so that New Type Efficient Desulfurization Equipment by Or electrostatic precipitator collection Lime/limestonegypsum wet desulphurization technology: after dedusting flue gas, lime or limestone slurry is used as desulfurizer China Flue Gas Desulfurization Equipment

China Desulfurization Technology, Flue Gas Treatment

The limestone/gypsum flue gas desulfurization technology is mature, easy to operate, management maturity; 2 The equipment has some advantages on desulfurization efficiency is as high as 95% above, the applicability of coal is strong and it can use any kind of sulfur coal, which is the most effective way of desulfurization;We specialize in Flue Gas Desulfurization System Crusher, Jaw crusher, China Crusher, Grinding Machine Top manufacturers of Crushers (Breaker), Jaw Crusher, Impact Crusher (Impactor), Ball Mill, Grinding Mill, Raymond Mill, Sand Making Machine, Sand Washing Machine Limestone desulfurization technology Mining Horizontal ball mills have dominated as the equipment of choice for limestone grinding functions within wet flue gas desulfurization (WFGD) systems crushing, screening, washing, grinding equipment in Limestone desulfurization mill Mining Quarry Plant

Desulfurization equipment worldcrushers

Desulfurization equipment Posted on May 27, 2013 by shuijing Flue Gas Desulfurization (Acid Gas Removal) Systems Granite Limestone Basalt Pebble Gravel Gypsum Marble Barite Quartz Dolomite Gold Ore Copper ore Other: Message: (As: Output 010,1015,1520mm for Crushing or 75 microns(200 mesh) for Grinding;) Limestone/limestonegypsum flue gas desulfurization uses limestone or lime as the desulfurization absorbent Limestone is crushed and ground into powder and mixed with water to form absorption slurry When limestone is used as absorbent, lime powder is digested and added with water to form absorbent slurryLimestone FGD – Ammonia FGD Technology Limestone Desulfurization Of Flue Gases Flue Gas Desulfurization Processes The process of FGD (Flue Gas Desulfurization) is designed to absorb the sulfur dioxide in the flue gas before it is released This is accomplished through either a wet or a dry processLimestone Desulfurization Of Flue Gases Grinder

PAPER OPEN ACCESS Progress of Desulfurization and

311 Wet flue gas desulfurization (1)Limestone/LimeGypsum Flue Gas Desulfurization The maximum efficiency of wet limestonegypsum desulfurization can reach 99%, which basically ensures that the SO2 concentration in the flue gas can meet the requirements of China Air Pollutant Emission Standard for Thermal Power Plants Innovations: firstly, the limestone powder aerodynamic field will be optimized, include the situation, angle and speed of jet to make mix fully so that improve the desulfurization efficiency Secondly, that is the steam return, it means that ash from high temperature separator on boiler exit and desulfurizer return to furnace by steam so that New Type Efficient Desulfurization Equipment by The limestone/gypsum flue gas desulfurization technology is mature, easy to operate, management maturity; 2 The equipment has some advantages on desulfurization efficiency is as high as 95% above, the applicability of coal is strong and it can use any kind of sulfur coal, which is the most effective way of desulfurization;China Desulfurization Technology, Flue Gas Treatment

Lime And Limestone Slurry Gas Desulfurization System

High quality Lime And Limestone Slurry Gas Desulfurization System Absorb Reactioncalcium Sulfite from China, China's leading biogas desulphurization equipment product, with strict quality control biogas purification equipment factories, producing high quality biogas purification equipment products pH equipment is used to control the feed rate of these chemicals PROCESS After fly ash removal, the flue gas (seen in Figure 1) is bubbled through the scrubber, and the slurry is added from aboveThe lime or limestone reacts with the SO 2 in the flue gas to create insoluble calcium sulfite (CaSO 3) as in the equations below Limestone: CaCO 3 Lime / Limestone Wet Scrubbing System for Flue Gas Desulfurization equipment Posted on May 27, 2013 by shuijing Flue Gas Desulfurization (Acid Gas Removal) Systems Granite Limestone Basalt Pebble Gravel Gypsum Marble Barite Quartz Dolomite Gold Ore Copper ore Other: Message: (As: Output 010,1015,1520mm for Crushing or 75 microns(200 mesh) for Grinding;)Desulfurization equipment worldcrushers

Limestone desulfurization mill Mining Quarry Plant

Limestone is important raw materials for cement industry First of all, you need vertical mill to pulverize limestone into 200mesh ~ 325mesh kefid will offer you best Wet Flue Gas Desulfurization (FGD) Systems – Gas Absorbers Limestone desulfurization technology BY admin March 27th, 2013 0 Wastewater Treatment for Flue Gas Desulfurization (FGD) at Wastewater Treatment for Flue Gas Desulfurization (FGD) At Electric Power Plants Wastewater Treatment for Flue Gas Desulfurization (FGD) at Electric Limestone desulfurization equipment Limestone desulfurization technology Mining The maximum efficiency of wet limestonegypsum desulfurization can reach 99%, which basically the old ammonium desulfurization equipment has been difficult to meet the desulfurization requirements, and the total dust of flue gas after desulfurization exceeds the standard (3) Dualalkali flue gas desulfurization PAPER OPEN ACCESS Progress of Desulfurization and

Corrosion evaluation of one wet desulfurization equipment

Corrosion evaluation of one wet desulfurization equipment – Flue gas desulfurization unit Fuel Processing Technology ( IF 4982Pub Date : , DOI: Yi Gong, ZhenGuo Yang A detailed process model of the wet limestone flue gas desulfurization system has been presented This model can be used to calculate indispensable parameters for estimating costs and next to minimize capital and operating costs The process model describes most important stage of SO2 removal running in an absorber and a holding tank It includes absorption of sulfur dioxide, oxidation Model of the Wet Limestone Flue Gas Desulfurization Innovations: firstly, the limestone powder aerodynamic field will be optimized, include the situation, angle and speed of jet to make mix fully so that improve the desulfurization efficiency Secondly, that is the steam return, it means that ash from high temperature separator on boiler exit and desulfurizer return to furnace by steam so that New Type Efficient Desulfurization Equipment by

Limestone Mill for Desulfurization Kefid Machinery

Limestone gypsum flue gas desulfurization wet process medium for the limestone powder, so the preparation of limestone powder has become a thermal power plant, steel desulfurization, improve the efficiency of desulfurization prerequisites Kefid after years of research and use, developed desulfurization milling equipment and technology Using limestone powder as desulfurizer of limestone gypsum wet desulphurization process high efficiency of desulfurization Using limestone powder as desulfurizer of limestone gypsum wet desulphurization process high yield Using limestone powder as desulfurizer of limestone gypsum wet desulphurization processLimestone Flue Gas Desulfurization System SupplierDesulfurization equipment Posted on May 27, 2013 by shuijing Flue Gas Desulfurization (Acid Gas Removal) Systems Granite Limestone Basalt Pebble Gravel Gypsum Marble Barite Quartz Dolomite Gold Ore Copper ore Other: Message: (As: Output 010,1015,1520mm for Crushing or 75 microns(200 mesh) for Grinding;)Desulfurization equipment worldcrushers

grinding mill for limestone desulfurization in power

The limestone powder produced by the grinding mill of has been applicate in desulfurization of various power plants well, and customers have achieved good economic benefits For different limestone flour, we can provide you with different solution and relevant grinding equipmentOptimization of the wet limestone (calcite) flue gas desulfurization (FGD) process is described, with the focus on the layout of subprocesses and equipmentTechnology Optimization of Wet Flue Gas The particle size of limestone powder for desulfurization is 250 mesh or 325 mesh (45 μ m), and the desulfurization effect of 325 mesh limestone powder is better To prepare such fine limestone powder, the mill mainly adopts Raymond mill, pendulum mill, ball mill or European mill In the past, Raymond mills and ball mills were used moreParticle size of limestone powder for desulfurization

Corrosion evaluation of one wet desulfurization equipment

Corrosion evaluation of one wet desulfurization equipment – Flue gas desulfurization unit Fuel Processing Technology ( IF 4982Pub Date : , DOI: Yi Gong, ZhenGuo Yang Abstract:This paper presented the analysis and process of one therm al power corporation 300MW coal—fired units of limestone— gypsum wet flue gas desulfurization equipment imposed anticorrosion absorber oⅡ.and that plug the limestone slurry nozzles湿法烟气脱硫装置效率低的原因及措施 North China GGH equipment itself and the direct investment it relates to, including gas duct, civil structures and auxiliary systems, account for 20% of the investment in desulfurization system (2) The pressure drop of GGH is normal about 1000 Pa together with the pressure loss of gas duct, the total increase in pressure loss is about 1200 PaResearch on desulfurization wastewater evaporation