عنا

مرحبا هل يمكنني مساعدتك؟

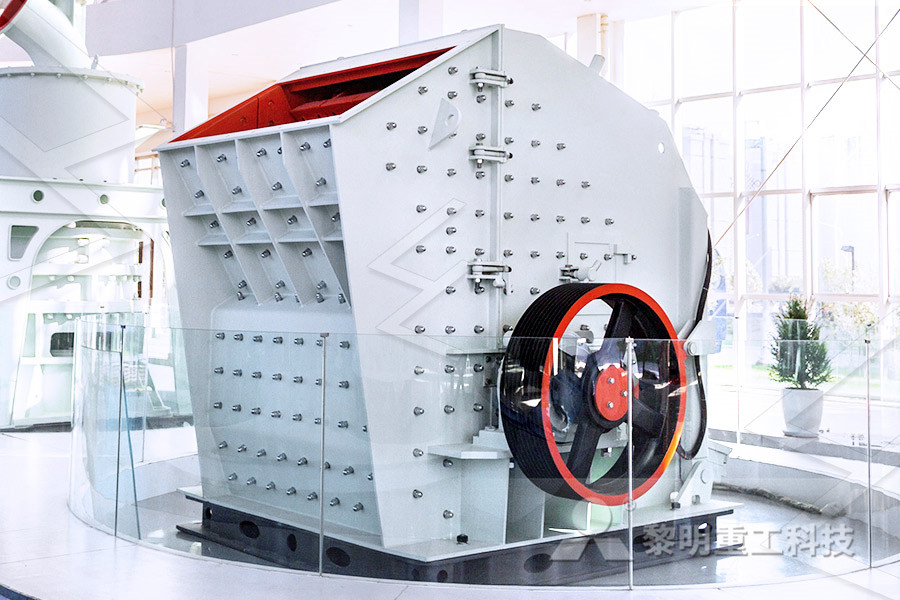

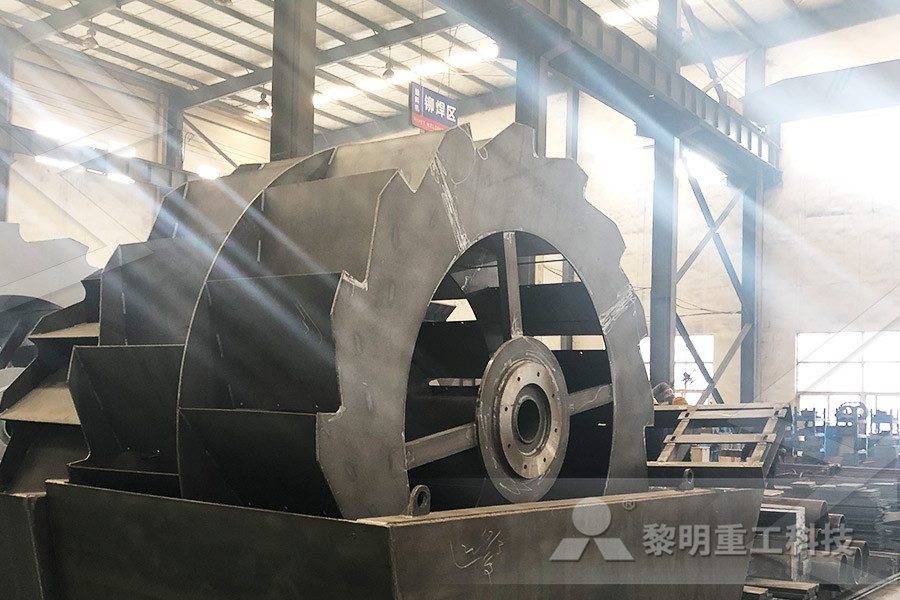

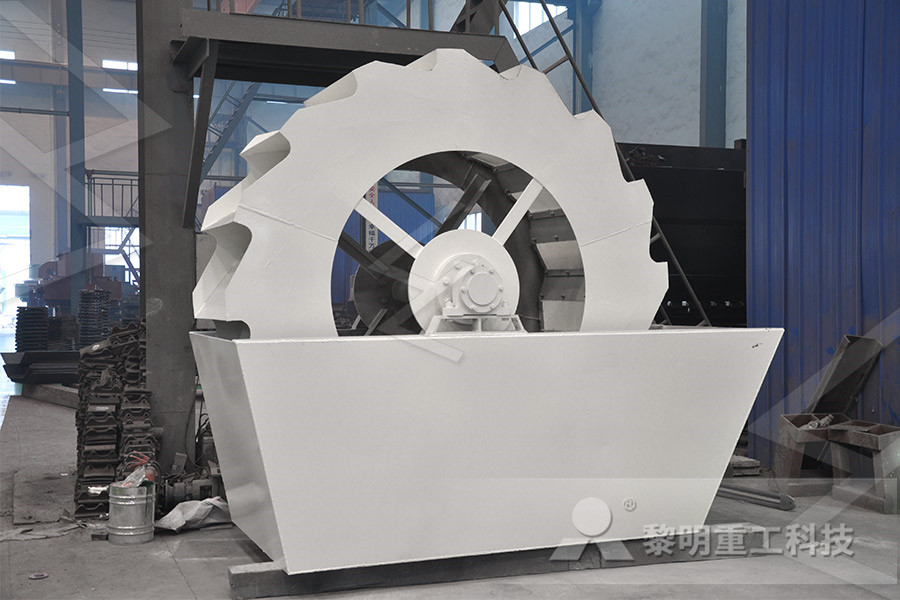

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Fine Mill With Rotor

2022-06-07T12:06:40+00:00

Fine Mill With Rotor balletuytenhovebe

Fine Mill With Rotor hotelplouhafr Fine Mill With Rotor As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of mineralsRotor Mills fine grinding with variable speed Rotor Mills The rotor mill series includes Ultra Centrifugal Mills, Rotor Beater Mills and Cross Beater Mills Depending on the particular instrument they are suitable for the preliminary and fine size reduction of soft, fibrous and also hard materialsRotor Mills fast easy sample preparation RetschPowerful and fast Rotor and Beater Mills are ideal for precrushing and fine comminution of soft to mediumhard, brittle, fibrous and temperaturesensitive materials in analytic laboratories or industry The sample is comminuted at high speed by impact and shearing forces The final fineness of the samples depends on the selected sieve insertRotor / Beater Mills – fritschde

Variable Speed Rotor Mill PULVERISETTE 14 premium line

Fast pre and finegrinding in one instrument The FRITSCH Variable Speed Rotor Mill PULVERISETTE 14 premium line offers impact, shearing and cutting comminution in one instrument – with a higher performance, better cooling and is significantly quieter than comparable instruments The rotor mill series includes Preliminary size reduction Sample dividers ultra centrifugal mills, rotor beater mills and cross beater mills Depending on the particular instrument they are suitable for the preliminary and fine size reduction of soft, fibrous and also hard materials A final fineness of down to 40 µm can often be achievedSize reduction with Rotor Mills McCroneThe combination of the FRITSCH Variable Speed Rotor Mill PULVERISETTE 14 classic line with the FRITSCH Cyclone separators is ideal for ultrafine grinding of temperaturesensitive samples like powder coatings and plastic samples or for smooth precrushingVariable Speed Rotor Mill PULVERISETTE 14 classic line

Variable Speed Rotor Mill PULVERISETTE 14 classic line

Effective comminution due to highest rotor speed The FRITSCH Variable Speed Rotor Mill PULVERISETTE 14 classic line is the ideal mill for fast, effective comminution of soft to mediumhard, brittle and fibrous materials as well as temperaturesensitive samples – The fine cutting mill CSZ for the size reduction of nonfriable and soft products By maximizing the cutting strokes (rotational speed of the rotor x number of rotor knives x number of stator knives) and the use of special screen inserts, highest finenesses can be achieved with this multiknife cutting mill The open rotor design increases the air CSZ Fine Cutting Mill NETZSCH Grinding DispersingFast pre and finegrinding in one instrument The FRITSCH Variable Speed Rotor Mill PULVERISETTE 14 premium line offers impact, shearing and cutting comminution in one instrument – with a higher performance, better cooling and is significantly quieter than comparable instruments Its powerful motor is ideal for the particularly fast comminution of soft to mediumhard, brittle as well as fibrous materials Variable Speed Rotor Mill PULVERISETTE 14 premium

OUTOTEC HIGMILL – ENERGYEFFICIENT HIGH

energyefficient fine and ultrafine grinding solution that relies on proven technology The mill takes advantage of gravitational forces and GrindForce™ rotor technology to produce a finer grind for mineral liberation OUTOTEC HIGMILL – ENERGYEFFICIENT HIGHINTENSITY GRINDING BENEFITS • High energy efficiency with patentedThe MPF Prallfiner enables the continuous processing of soft to mediumhard materials into slim fine flakes or wooden powder After passing the VC Vibration Conveyor, the permanent magnet drum and the HPS Heavy Particle Separator, the material is fed from the rear side into the grinding chamber where it is milled between the rotor beater ledges and the grinding trackRotor mill MPF series Dieffenbacher for wood / The Rotor Beater Mill SR 300 is suitable for coarse and fine size reduction, either in batches or continuously It can process dry, soft, mediumhard, organic and inorganic substances With its adjustable speed of 3,000 to 10,000 rpm the rotor beater mill SR 300 is intended for universal use: from sample preparation in laboratories up to Rotor Mills Glen Mills, Inc

Fine cutting mill All industrial manufacturers Videos

rotor mill PULVERISETTE 19 Rotational speed: 300 rpm 3,000 rpm CONDUX CSZ Fine Cutting Mill is the ultimate device used in the size reduction of nonfriable and soft products The device is capable of providing fine cuts, Rotor and Beater Mills are ideal for precrushing and fine comminution of soft to mediumhard, brittle, fibrous and temperaturesensitive materials in analytic laboratories or industry The sample is comminuted at high speed by impact and shearing forces The final fineness of the samples depends on the selected sieve insertRotor / Beater Mills – fritschdeFine Cutting Mill AFS from Hosokawa Alpine are commonly used in the size reduction of soft, mediumhard, fibrous and tough materials A rotor inside the mill revolves at high speed Different rotor geometries make mills adaptable to different material properties (mediumhard, soft, fibrous or elastic materials)Fine cutting mill Vekamaf industry experts

RoStar™ Vertical High Intensity Ultrafine Grinding

The mill has a compact design giving high power density (kW/m 3) connected with a small footprint The design of the RotorStator arrangement is unique amongst the range of ultrafine Fig Fine Impact Mill 315UPZ The UPZ is a highspeed impact type fine grinding machine that can be equipped with 4 different types of hammers and 3 types of liners/screens By equipping the machine with variations of the hammers and liners/screens, the machine can process various types of raw materials and achieve a wide range of particle sizesFine Impact Mill UPZ HOSOKAWAMICRON Rotor blades are easily replaced without further rotor balancing needed Prater Fine Grinders utilize a highspeed impact principle The feed material is metered into the center of the mill, where it is impacted by the rotor The feed material is then thrown outward where it impacts with other particles, aiding in the reduction process M Series Fine Ginder Commercial Dry Grinder

Impact Mill Condux NETZSCH Grinding Dispersing

Impact Mill Condux ® with integrated Classifier The newly designed Condux ® Impact Mill with an integrated dynamic air classifier is used when the desired final fineness cannot be achieved with conventional screenless pin mills or blast mills with screen inserts In contrast to conventional classifier mills, the grinding disc and classifier wheel are torqueproof connected to each other and (Page 1) Many branches of the chemical process industries (CPI) make use of impact comminution to process solid matter, such as minerals, foodstuffs, pharmaceutical products, and above all, products for the chemicals industry Impact comminution is also used for coarse crushing, but the focus of this article is fine grinding with endproduct particle sizes below 500 micronFine Grinding With Impact Mills Chemical rotor mill is a current super fine grinder which is suitable for grinding of inorganic and organic substance, it possess the most advanced mechanism of ultrasonic waves pulverization and spraying function, it can produce the high slight frequency vibration, and have dual function of drying and grinding simultaneouslyChina Customized OEM Rotor Mill Factory Produce

Rotor / Beater Mills – fritschde

Rotor and Beater Mills are ideal for precrushing and fine comminution of soft to mediumhard, brittle, fibrous and temperaturesensitive materials in analytic laboratories or industry The sample is comminuted at high speed by impact and shearing forces The final fineness of the samples depends on the selected sieve insertFine Cutting Mill AFS from Hosokawa Alpine are commonly used in the size reduction of soft, mediumhard, fibrous and tough materials A rotor inside the mill revolves at high speed Different rotor geometries make mills adaptable to different material properties (mediumhard, soft, fibrous or elastic materials)Fine cutting mill Vekamaf industry expertsUltrafine sand Thanks to the narrower milling gap and the higher circumferential speed of the rotor, the material in the RPMF rotor impact mill is exposed to more intense stress The result, in percentage terms, is a higher proportion of fine sand in the grainsize range from 0 to 2 mmRotor impact mill – sand maker with a vertical shaft

SR 300 Rotor Beater Mill Glen Mills, Inc

The Rotor Beater Mill SR 300 is suitable for coarse and fine size reduction, either in batches or continuously It can process dry, soft, mediumhard, organic and inorganic substances With its adjustable speed of 3,000 to 10,000 rpm the rotor beater mill SR 300 is intended for universal use: from sample preparation in laboratories up to Rotor diameter mm 300 500 Working width mm 600 1 000 Max speed min1 1 300 1 070 Rotor knife rows pcs 3/5 9/16 Stator knife rows pcs 4 6 9 Drive power kW 22 30 55 110 Inlet opening mm 190 x 650 300 x 1 000 Air volume (nom) m3 h1 1 080 2 800 Weight (approx) kg 2 200 6 500 NETZSCH Fine Cutting Mill CS 500/10007Z with niproll systemNETZSCH Fine Cutting Mill CSZRotor blades are easily replaced without further rotor balancing needed Prater Fine Grinders utilize a highspeed impact principle The feed material is metered into the center of the mill, where it is impacted by the rotor The feed material is then thrown outward where it impacts with other particles, aiding in the reduction process M Series Fine Ginder Commercial Dry Grinder

DE3A1 Fine mill and operating method

The present invention relates to a fine mill (1) comprising a cutting rotor (3) with a plurality of cutting blades (4), in particular distributed uniformly around its circumference, a cutting stator (5) surrounding the cutting rotor (3) with a plurality of stator blades (6) , a Mahlguteinlass (7) for Mahlgutzufuhr and a downstream in the direction of rotation of the cutting rotor (3) after Impact Mill Condux ® with integrated Classifier The newly designed Condux ® Impact Mill with an integrated dynamic air classifier is used when the desired final fineness cannot be achieved with conventional screenless pin mills or blast mills with screen inserts In contrast to conventional classifier mills, the grinding disc and classifier wheel are torqueproof connected to each other and Impact Mill Condux NETZSCH Grinding DispersingGMP fine milling for Pharmaceutical, Chemical and Food industries The HammerWitt Lab and the MFH Hammer Mills from Frewitt deliver the optimum crushing results at an excellent throughput for pharmaceutcial products, chemicals and food ingredients The Hammer Mill produces very fine particles and is particually suited for milling hard cyrstalline or fibrous productsFrewitt HammerWitt MFH Hammer Mill S3 Process