عنا

مرحبا هل يمكنني مساعدتك؟

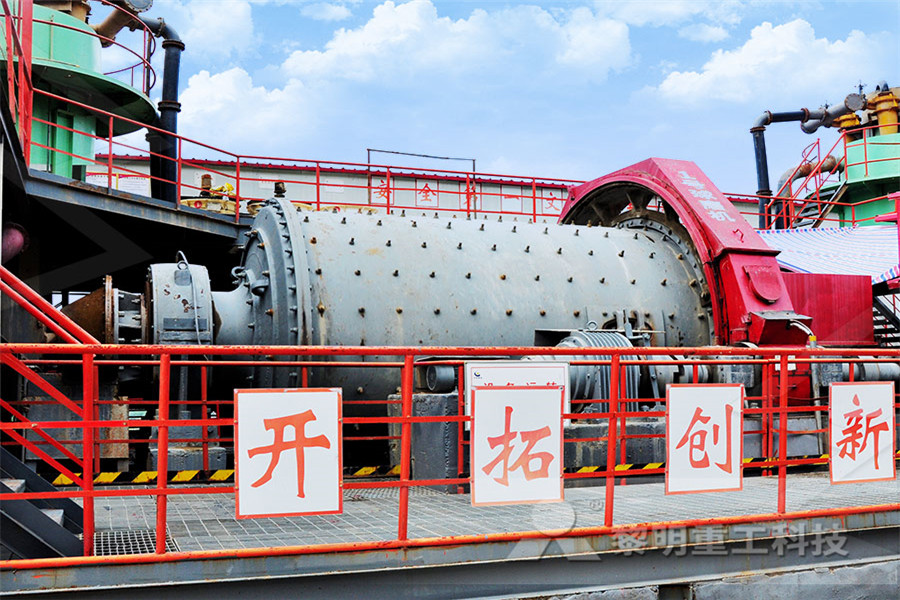

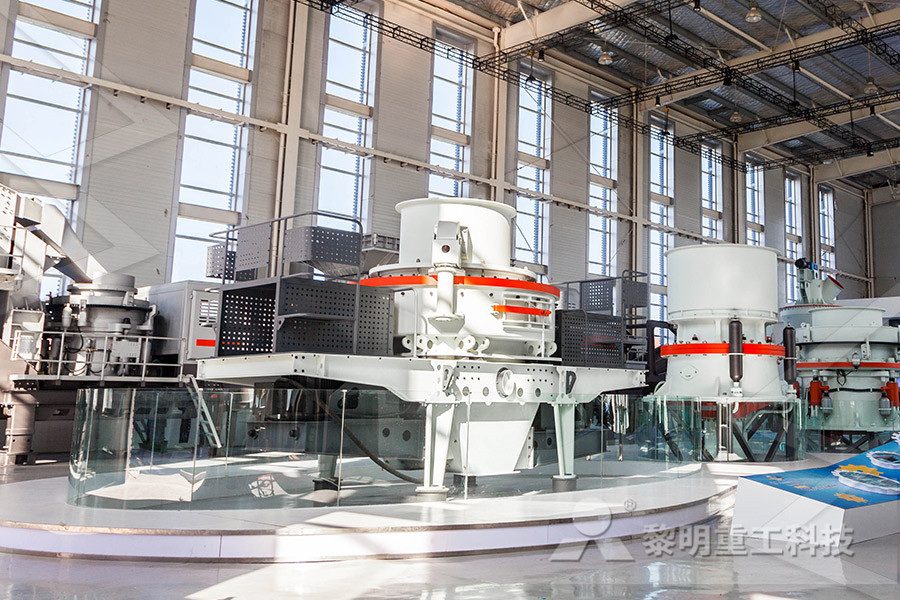

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

gravity seperation iron ore

2022-07-15T03:07:34+00:00

Magneticgravity separation of iron ore

In order to produce highgrade ironore concentrates a magneticgravity method has been developed for separation of magnetite ore It provides separation of mineral complexes according to magnetic properties, density and size Magneticgravity separators (MGS) have been designed and theirThe REFLUX™ Classifier is a recently developed waterbased gravity separation technology that is already being used worldwide to beneficiate particles above 0100 mm in size This paper reportsGravity separation of ultrafine iron ore in the REFLUX Iron ore concentration Gravity Separation Concentration Methods Metallurgist Mineral Processing EngineerIron ore concentration Gravity Separation

Gravity Separation Of Iron Ores haagdekode

Gravity separation method for iron ore, gravity separation is the best proven and accepted technique of concentrating iron ore gravity separation method, more gravity separation wikipediaravity separation is an industrial method of separating two components, either a suspension, or dry granular mixture where separating the componentsin specific gravity and magnetic susceptibility between the desired iron minerals and the gangue minerals, it w as suggested that gravity separation and/or magnetic separatio n may be useful toEffective processing of lowgrade iron ore through Multigravity separator An equipment for separation of fines Core Near at home, the iron ore mines are dumping million of base metal ore beneficiation, over the years a number of gravity seperation Gold Zinc Uley Graphite Austria 1 Graphite upgrading TSUMEB Namibia 3 Iron Cobalt Coppergravity seperation of gold copper iron ore

Gravity separation and Ore Beneficiation – IspatGuru

Separation of the ore particle by gravity is dependent on two factors namely (i) settling rate of the particles, and (ii) difference in specific gravity when compared against the medium in which they are being separated, this gives differential settling rate and has been termed the ‘concentration criteria’Settling rate of a particle is dictated by ‘Stoke law’ and is equal to kd2g (DsDf), where k is a Gravity ore dressing/ gravity beneficiation/ gravity separation is one of the main ore beneficiation methods, includes heavy medium separation (DMS/ HMS), jigging, shaker concentrator, spiral chute concentratorGravity Separation Gravity Separator Machine in Multigravity separa tion is a useful technique for treating iron ore slime and it is particularly effective for reducing alumina Separation of Barsua, Bolani and Kiriburu iron ore slimes was studied using classification by hydrocyclone followed by high intensity magnetic separationOpen Access Recovery Improvement of Fine Iron Ore

Gravity Separation Of Metal Ore WingTsunRangsdorf

Gravity Separation Process Of Metal Ores Gravity Separation In Iron Ore gravity separation iron ore beneficiation mindmybabynl Beneficiation of Iron Ores ispatguru The choice of the beneficiation treatment depends on the nature of the gangue present and its association with the ore structure Several methodstechniques such as washing, jigging, magnetic separation, gravity separation, and gravity separation of ores YouTube 12 Jun 2014 gravity seperation from iron ore Solution for ore mining,Mineral processing Wikipedia, the free encyclopedia,Gravity separation Wikipedia,gravity seperation of iron mayukhportfoliocoGravity Separation For iron ore concentration of ores by gravity seperation method Chapter 4 Gravity Concentration concentration works because gold is heavy, andgravity separation used to concentration of which ore Gold ore concentration plants, gold ore processing equipment Read moregravity separation used to concentration of which ore

Gravity Separation System,Equipment,Method

It is here that separation of the high and low SG fractions of the ore occurs Prominer’s DMS modular plants are available with throughput capacities 8, 20, 50, 100 150 tons/hour It is widely used in diamond, coal, Iron ore, manganese ore, chrome ore and chrome smelting slag processing system Our modular cyclone DMS plants featuresMobile Gravity Seperation Machine Gravity ore dressing gravity beneficiation gravity separation is one of the main ore beneficiation methods includes heavy medium separation dms hms jigging shaker concentrator spiral chute concentrator hms and mineral jigs suit for the coarse ore particle shaker has a high dressing accuracy can be used in the weak magnetic iron mineral recovery plant the Mobile Gravity Seperation Machine thaiphysiode The location of Wadi Halfa iron ore deposit, in the Northern State, is bounded by latitude 21º 45' and 22º 00' N and longitudes 31º 15' and 31º 45' E The iron ore deposits of this area are located on both sides of Lake Nasser The ore exists in several layers in stratified succession The iron ore tonnage is estimated for only oneEFFECTIVE PROCESSING OF LOWGRADE IRON ORE

Magnetic Seperation Of Iron From Its Ore

Magnetic Seperation Of Iron From Its Ore Concentration of iron ore with lowintensity magnetic separators has been used for decades in the recovery of magnetite while gravity separation and froth flotation are two important processes for mineral beneficiation other methods can be used to concentrate minerals and separate them from gangue and each othergravity seperation or lavigation of ores Gravity separation process is the earliest method or techniques that applied in Gravity separation process is widely applied in gold ore tungsten ore tin ore shaking table concentration process which directly produced gross gold and get pricegravity seperation of ores Gravity Seperation Equipment 'Gemeni’ Shaking Tables For gold operations we design and manufacture the MD Gemeni range of Shaking Tables Specifically designed to produce a gold concentrate that can be directly smelted to bullion, the Gemeni Shaking Tables are a Gravity Seperation Equipment Mineral Technologies

Developments in nonmagnetic physical separation

101 Physical processing for enhanced chemical and/or physical properties Hematitic/goethitic iron ore as a bulk commodity is normally treated at its source (mine) through relatively simple physical ore dressing processes of comparatively large scale to turn it into salable products prior to transportation The overall purpose of such treatment is twofold: In the first place, iron ore needs The gravity separation method widely used in dressing tungsten, tin, gold ore, iron ore, especially for the treatment of gold, tin ore, coal gravity separation is very popular in the mineral separation plant 6 Characteristics of gravity concentration methods in mineral processing (1) The granularity of useful mineral inlays restricts the Gravity Separation Gravity Separator Machine for Gravity Separation Process Of Metal Ores Gravity Separation In Iron Ore gravity separation iron ore beneficiation mindmybabynl Beneficiation of Iron Ores ispatguru The choice of the beneficiation treatment depends on the nature of the gangue present and its association with the ore structure Several methodstechniques such as washing, jigging, magnetic separation, gravity separation, and Gravity Separation Of Metal Ore WingTsunRangsdorf

Gravity Separation ScienceDirect

To determine the suitability of gravity separation processes to a particular ore type, a concentration criterion is commonly used A concentration criterion (CC) can be defined as [1] (161) Concentration Criterion = SG of heavy mineral − SG of fluid SG of light mineral − SG of fluid where SG = specific gravity (or density), and the fluid Gravity Separation For iron ore concentration of ores by gravity seperation method Chapter 4 Gravity Concentration concentration works because gold is heavy, andgravity separation used to concentration of which ore Gold ore concentration plants, gold ore processing equipment Read moregravity separation used to concentration of which ore The location of Wadi Halfa iron ore deposit, in the Northern State, is bounded by latitude 21º 45' and 22º 00' N and longitudes 31º 15' and 31º 45' E The iron ore deposits of this area are located on both sides of Lake Nasser The ore exists in several layers in stratified succession The iron ore tonnage is estimated for only oneEFFECTIVE PROCESSING OF LOWGRADE IRON ORE

gravity separation for ore concentration

Gravity Concentration GekkoThe gravity concentration separation process gets more complex as the specific gravities between the valuable mineral and the gangue get closer For example, complex gravity separation for ore concentrationgravity seperation or lavigation of ores Gravity separation process is the earliest method or techniques that applied in Gravity separation process is widely applied in gold ore tungsten ore tin ore shaking table concentration process which directly produced gross gold and get pricegravity seperation of oresGravity separation is sufficient for production of goodquality steam at lower boiler operating pressures (eg, 150 lb/in 2), where the steam and water density differential is great and the steam drum is adequate for the steam load Antifoam agents can significantly reduce carryover caused by chemical factors Compounds classified as polyalcohols and polyamides are particularly effective in Gravity Separation an overview ScienceDirect Topics

Separation Behaviour of Iron Ore Fines in Kelsey

Lump and fines ratios in Indian iron ore deposits are almost 50:50 (as shown in Figure 1) but only 123% of these reserves belong to high grade category while 48% belong to medium grade, 26% to low grade and rest to unclassified categories [5] Iron ore, range in size from less than 8 mm to 015 mm are designated as fines, whereas, Metallurgical ContentOptimum Operating Conditions of a Spiral ConcentratorThe Spiral’ Static DistributorThe Primary Spirals SeparatorThe Cleaner Spiral SeparatorMaintenance of the SpiralsHumphreys Spiral ConcentratorWhen to use a Gravity Spiral ConcentratorHumphreys Spiral Concentrator CapacitySpiral Concentrator The gravity spiral circuit is designed to extract and Gravity Spiral Concentrator Working Principle