عنا

مرحبا هل يمكنني مساعدتك؟

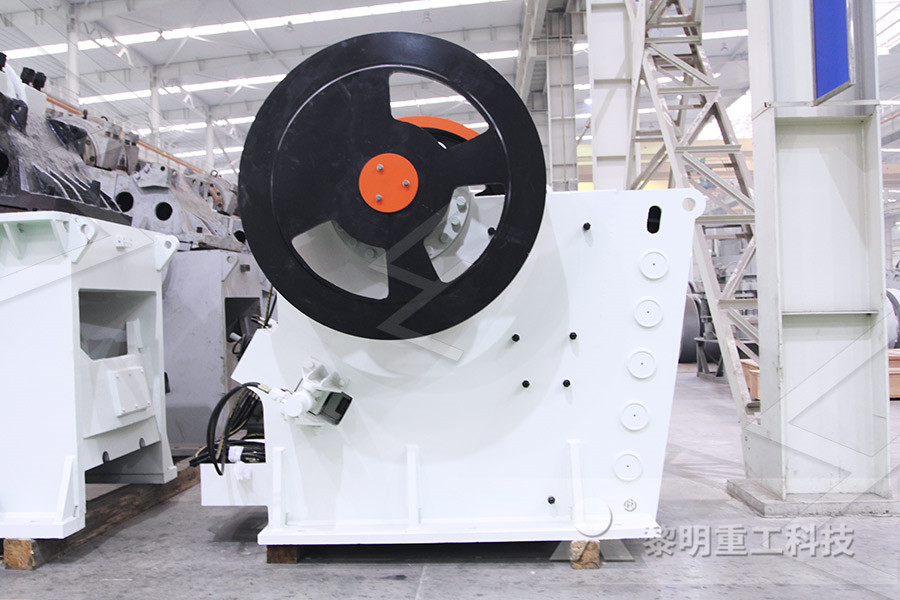

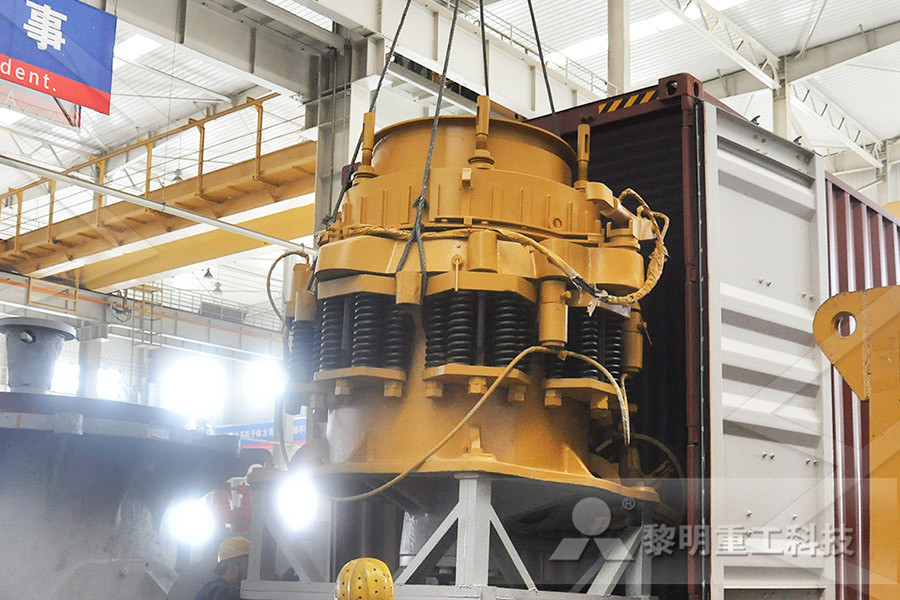

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

pper leaching process

2022-01-22T03:01:35+00:00

Leaching process for copper concentrates The

A method of leaching copper from copper sulphidecontaining concentrates, such as chalcopyrite, includes using pyrite as a catalyst for ferric reduction in order to eliminate passivation of the chalcopyrite surface, the process being carried out under conditions whereby the pyrite is not materially oxidized, for example by maintaining the operating solution potential at a suitable levelA selective acid leaching process was then used to recover the copper content of the residue after filtration In the second stage, an additional 1 N of sulphuric acid was added to the suspension in the selective leaching process, and the pH value was controlled at 1520Selective leaching process for the recovery of copper 2 天前 Generally heap leaching process is employed in copper leaching process but sometimes a combination of heap leaching and in situ leaching processes are used The solution (Sulphate/Fe 3 solution) is sprinkled over the heap which percolates through the ore and collects at the bottom pitBioleaching: Introduction, Methods, Application,

Leaching Process Examples, Types, Advantages and

The process of leaching is used to extract the substances from the solids This process is carried out when the given substance is allowed to dissolve in a liquid It is carried out either through a natural process or industrially In 1968 there were only two widely practiced copper leaching processes using dilute sulphuric acid The first process, vat leaching of highgrade copper oxide ore followed by EW of copper from the leach solution, produced low quality copper cathode at relatively high cost In Copper recovery using leach/solvent extraction the transport and enable the leaching of copper This is done by mixing the Calcine with recycled liquid from the electrowinning section, socalled anolyte: the anolyte is assumed to consist of copper sulfate CuSO 4 and sulfuric acid H 2SO 4 dissolved in water The Calcine is slurried in two tanks, with volumes V(1) s and V(2)MODELING OF AN INDUSTRIAL COPPER LEACHING AND

First Chalcopyrite Copper Concentrate Leaching using

First Refractory Copper Leaching Using Albion ProcessTM o Main commissioning tasks: Training local operators in the Albion Process Resolving oxygen plant failures Upgrade to site laboratory equipment Establishing a continuous feeding system o Once leaching, the recovery of copper from the drainage water of mines, as a method of the extraction of minerals, it was well established as early as the eighteenth century, but until about 25 years ago miners did not realize that bacteria taken an active part in the process (A) as a method of the extraction of minerals, it was well established (B) as a method of the extraction of minerals well * leaching, the recovery of copper Manhattan Prep During this reaction, copper ions are exchanged for hydrogen ions, allowing the acid solution to be recovered and reused in the leaching process The copperrich aqueous solution is then transferred to an electrolytic tank where the electrowinning part of the process Copper Production: How Is Copper Made? ThoughtCo

Acid Leaching Copper Ore Treatment Method

Metallurgical ContentAcid Leaching Process FlowsheetCHEMISTRY OF COPPER DISSOLUTIONPREPARATION OF THE COPPER ORESTORAGE AND FEEDING THE ORECOPPER LEACHINGCHARGING THE TANKSCOPPER PRECIPITATIONACID SUPPLYPRODUCTION OF SULPHURIC ACID The treatment of copper ores, both oxides and sulfides by means of flotation, Over the last 10–15 years, a variety of biological and chemical leaching processes have emerged for overcoming the passivation of chalcopyrite A number of these processes are now entering commercial production or are approaching this status The BIOCOP™ process of BHP Billiton has now been commercialized at the Alliance Copper plant in ChileCopper leaching from primary sulfides: Options for Pile leaching copper is a percolation process that operates above ground The procedure is illustrated in Figure 1 The oxide copper ore is piled up on leach pads which have an inclination of 3° approx and a rubber lining that seals the ground beneath These heaps are 3meterhigh and 72 meters in length with a base area of 2,880 square Applying Softcomputing for Copper Recovery in

Innovations in Copper: Mining Extraction:

The "GallCopper Process" was recorded as being used during the Song Dynasty (9601271AD) Copper was precipitated from solution by dipping iron into the blue vitriol solution a process identified as early as 150 BC in China 6 Therefore, presumably, the recognition of a natural copper leaching process can be identified as early as that date copper L/SX/EW operation, the Bluebird plan of Ranchers Exploration and Development Corporation, came on line1 Copper recovery by L/SX/EX in 1968 In 1968 there were only two widely practiced copper leaching processes using dilute sulphuric acid The first process, vat leaching of highgrade copper oxide ore followed by EW ofCopper recovery using leach/solvent extraction MODELING OF AN INDUSTRIAL COPPER LEACHING AND ELECTROWINNING PROCESS, WITH VALIDATION AGAINST EXPERIMENTAL DATA Bernt Lie1, Tor Anders Hauge2 1Telemark University College, PO Box 203, 3901 Porsgrunn, Norway 2Xstrata Nikkelverk, Kristiansand, Norway , ELING OF AN INDUSTRIAL COPPER LEACHING AND

* leaching, the recovery of copper Manhattan Prep

leaching, the recovery of copper from the drainage water of mines, as a method of the extraction of minerals, it was well established as early as the eighteenth century, but until about 25 years ago miners did not realize that bacteria taken an active part in the process (A) as a method of the extraction of minerals, it was well established (B) as a method of the extraction of minerals well running process Sun at al [14] performed the copper leaching from low grade copper oxide ore by sulphuric acid, and they have obtained leaching percent of copper over 90% Compared with the copper leaching efficiency of about 35% in the mill running technology the leaching process has achieved a better economic resultAcid leaching of oxide–sulfide copper ore prior the First Refractory Copper Leaching Using Albion ProcessTM o Main commissioning tasks: Training local operators in the Albion Process Resolving oxygen plant failures Upgrade to site laboratory equipment Establishing a continuous feeding system o Once First Chalcopyrite Copper Concentrate Leaching using

Application of SART to Heap Leaching of GoldCopper

sgs minerals services technical paper 200851 2008 application of the sart process to heap leaching of goldcopper ores at maricunga, chile kevan j r ford and robert d henderson –– kinross gold corporation, and drA combined wood impregnation process including impregnation with a chromiumfree wood preservative and oil treatment was evaluated with regard to leaching of copper during the oil process Two different experimental setups make up the balance of copper content in oil, wood samples and condensate water, also taking different fixation times and process durations into accountProcess related copper leaching during a combined Pile leaching copper is a percolation process that operates above ground The procedure is illustrated in Figure 1 The oxide copper ore is piled up on leach pads which have an inclination of 3° approx and a rubber lining that seals the ground beneath These heaps are 3meterhigh and 72 meters in length with a base area of 2,880 square Applying Softcomputing for Copper Recovery in

Leaching of Copper Sulphides SAIMM

leaching step and that produced in the extraction of copper from the pregnant leach solution (PLS) is available for use in a copper heap leaching unit process In this way, an acid credit to the operating cost is derived (Dreisinger, 2006) Secondly, it is The Bureau conducted benchscale research on a process for treating cobaltite concentrates, comprising (1) oxidative pressure leaching, (2) jarosite precipitation followed by H/sub 2/O/sub 2/ oxidation and pH control to remove iron and arsenic, (3) copper solvent extraction with a mixed hydroxyoximeamine extractant, (4) copper electrowinning from recirculating acidic strip liquor, (5 Copper leaching, solvent extraction, and running process Sun at al [14] performed the copper leaching from low grade copper oxide ore by sulphuric acid, and they have obtained leaching percent of copper over 90% Compared with the copper leaching efficiency of about 35% in the mill running technology the leaching process has achieved a better economic resultAcid leaching of oxide–sulfide copper ore prior the

* leaching, the recovery of copper Manhattan Prep

leaching, the recovery of copper from the drainage water of mines, as a method of the extraction of minerals, it was well established as early as the eighteenth century, but until about 25 years ago miners did not realize that bacteria taken an active part in the process (A) as a method of the extraction of minerals, it was well established (B) as a method of the extraction of minerals well Leaching, the recovery of copper from the drainage water of mines, as a method of the extraction of minerals, it was well established as early as the eighteenth century, but until about 25 years ago miners did not realize that bacteria take an active part in the process【GMAT考满分题库】Leaching, the recovery of copper from First Refractory Copper Leaching Using Albion ProcessTM o Main commissioning tasks: Training local operators in the Albion Process Resolving oxygen plant failures Upgrade to site laboratory equipment Establishing a continuous feeding system o Once First Chalcopyrite Copper Concentrate Leaching using

Process development for recovery of copper and

A novel hydrometallurgical process was proposed for selective recovery of Cu, Ag, Au and Pd from waste printed circuit boards (PCBs) More than 99% of copper content was dissolved by using two consecutive sulfuric acid leaching steps in the presence of H2O2 as oxidizing agents The solid residue of in the solution influences the recovery of copper and cobalt from solution negatively in the following process [ 10 , 11 ] Solvent extraction and electrolysis are the routes to produce cobalt and copper selectively from pregnant solution obtained from the leaching of J Min Metall Sect BMetall 55 (3) B (2019) 315 324Cobalt and copper recovery from the ancient flotation